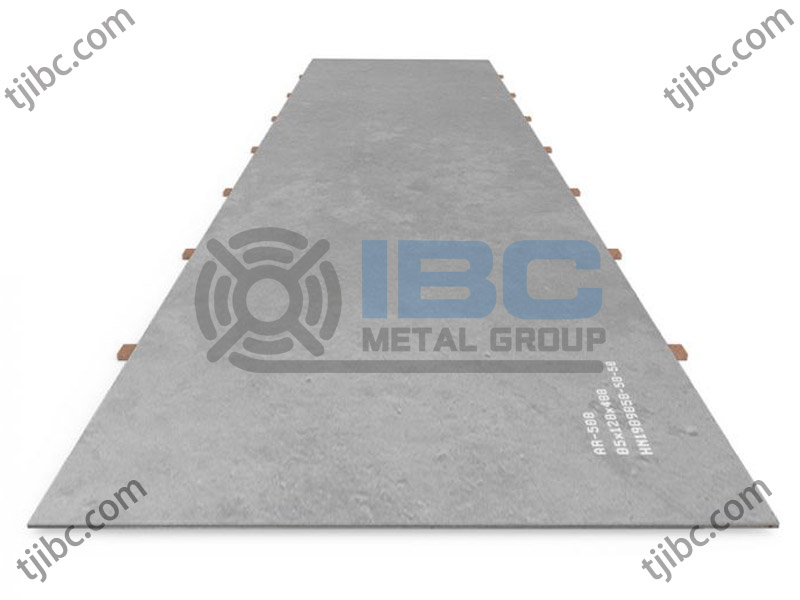

IBC Metal Group supplies wearalloy 500, a leading product of AR500 steel plate. Our experienced team is available to help you find the perfect solution for your wear issue, and our plate offers numerous advantages compared to other carbon-steel items. From ½ to 4 inches thick, the 500 grade steel is tough and lightweight, providing a higher durability than many other materials. It also withstands extreme conditions, making it an ideal choice for any application that requires abrasion resistance. Thanks to its membership in the AR family, this steel plate will protect against substantial amounts of wear and abrasion.

Sizes Offered

AR500 Steel Plate comes in a wide range of thickness and grades that offer maximum protection for all your application needs.

- Thickness: 1/8” thru 4”

- Widths: 48” thru 96”

- Lengths: 96” thru 288”

Other sizes could according to your customized.

For more information, or you need this product in your projects, please contact with us today!

What is Wear-alloy AR500?

Wearalloy 500, or AR500, is a specific type of abrasion resistant steel that is created by a heat treatment that through-hardens the steel to create a high impact structure. It is a grade of abrasion resistant (AR) steel plate that is known for its hardness, toughness, and resistance to wear and tear. This grade has one of the highest levels of hardness out of the common AR steel plate grades – with a Brinell Hardness Number (BHN) of between 460-544 – and is typically used in high-wear and impact applications. AR500 steel plate meets ASTM E10 specifications for Brinell hardness testing.

Properties

The high-carbon composition and additional chemical alloys included in AR500 steel give the material enhanced hardness and wear resistance. However, the addition of high amounts of carbon also reduces the formability and strength of AR500 as compared to other steel plate grades.

Compared to mild carbon steel grades and HSLA steel grades, AR500 is also more rigid and, therefore, less machinable. A heat-treatment process known as quenching and tempering further enhances the properties of AR500 for high-wear applications. The heat treatment process makes steel tougher and bitterer by changing the grain structure of the material.

Benefits of Wear-alloy AR500 Steel

AR500 steel lasts 3 times as long as other carbon-alloy steel. The toughness of the steel is what makes the AR500 stand out from other hard steels. It has high weldability and formability without losing its differential properties. The light design can take heavy blows without the risk of deformity, cracking, and other propagation if a local crack does occur. Additional benefits AR500 steel offers that include:

- Improves the longevity of products by reducing erosion

- Extremely reliable

- Maximizes production

- Cost-effective in the long run

- Requirements for AR500 Steel

The main benefit of AR500 steel plate, like any abrasion resistant steel, is its ability to resist wear and abrasion. Because of this, it can lead to less down time and can improve the longevity of your equipment by reducing erosion and wear. All of this, in turn, can lead to maximized production time.

AR500 steel plate is extremely tough and hardwearing, making it ideal for applications that require materials able to withstand considerable wear. Its durability also provides significant cost savings, as the material does not need to be replaced as often as those of lesser abrasion resistance. Learn more about abrasion-resistant steel and the differing qualities of AR400, AR450, and AR500.

Industries & Applications

AR500 is often employed in applications that require an exceptionally resilient material to resist wear and impact. In material handling, such as concrete handling machines, and other industrial manufacturing uses, AR500’s durability is advantageous. Ablation resistance also makes this steel ideal for mining, construction, and other industries that necessitate prolonged exposure to destitute conditions. AR500 plates are frequently employed in the creation of truck beds, buckets, chutes, hoppers, bulldozers, excavators, underground miners’ equipment, truck plows and dump liners.

Our AR500 steel plates meet all flatness and thickness requirements the 50% standards that are specified in ASTM A-6. All of the mechanical properties for the abrasion resistance steel matches the ASTM E10.

Other Applications List

| Chain Conveyors | Shakeout Liners | Crusher Plates | Wear Guides | Hammers |

| Mixer Components | Truck Bed Liners | Cutting Edges | Coal Chutes | Screens |

| Inspection Plates | Ballistic Targets | Bucket Liners | Impact Pads | Fan Blades |

| Various Hoppers | Chipper Blades | Screw Flights | Wear Rings | Levelers |

Available services: drilling and machining; Shearing and Punching; Forming Fabrication; AR500 steel plates are versatile and can be used in critical components in industries such as: Aggregation; Asphalt; Cement; Mining; Power; Pulp / paper; Sand & gravel; Scrap; Slag.

Conclusion

IBC (Tianjin) Industrial Co., Ltd produce & export AR500 steel plate to all over the world. We use Abrasion resistant steel plate grade in high-wear applications, such as in mining equipment and concrete handling. Due its surface hardness can range between 470-540 BHN. Possesses excellent resistance to slide wear, rub wear and heavy wear. Abrasion Resistant 500 Steel Plate can withstand high-impact stresses, even at extremely low temperatures. Its composition and hardening processes differ between mills. Mill test reports are supplied with each order. There are is no limit to the applications that can use AR500 steel. For more information, please contact with IBC Metal Group.

Contact with IBC Metal Group!