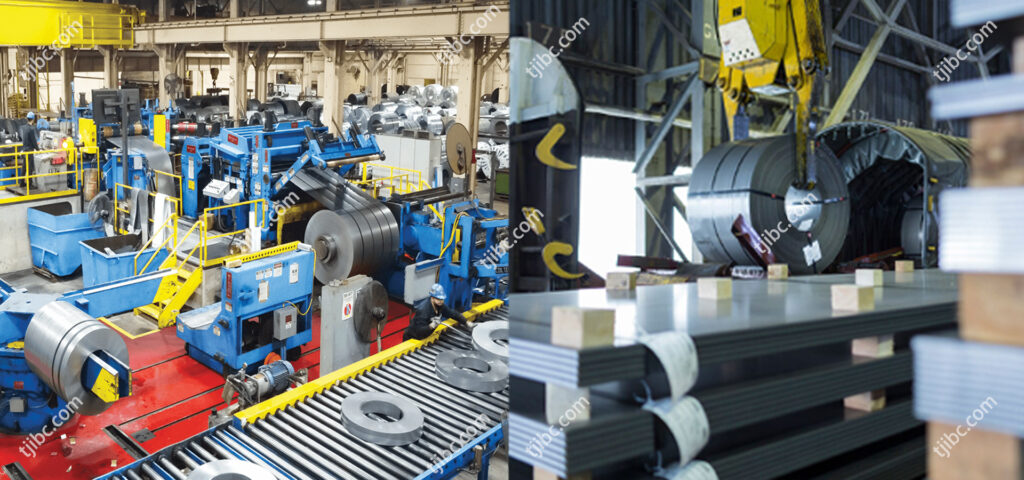

Automotive Steel Coil Manufacturer & Supplier

For the past decades, hot rolled steel products and cold rolled steel products have been the most important materials in the automobile industry. In addition to meeting increasingly stringent automotive engineering requirements, IBC Metal Group’s steel products are also cost-effective in terms of cost, service life and flexibility in strength. Rework of corrections can also performed very effectively with the steel product.

IBC is Your Best Automotive Steel Suppliers

For the manufacture of automobile structures, we mainly used cold rolled coils. Vehicle bodies mainly manufactured with cold rolled steel plates with a thickness of 0.5 to 1.5mm. Non-alloy materials with high formability and design freedom preferred earlier.

IBC Metal Group’s high quality cold and hot rolled coil steel adapted to various steel specifications. It is the core material of the automobile industry. We mainly used for the shell and structure of vehicles. Aside from deep drawing and drawing molding, welding, joining and painting are also important criterions for processing. High strength steels are also capable of meeting these needs.

Application of Automotive Steel in Automotive Industry

According to the international organization of automobile manufacturers, 95.6 million vehicles produced in 2018. Each car uses an average of 900 kilograms of hot and cold rolled automotive steel coil. The use of steel products in the vehicle is as follows:

- Firstly, 34% for body structure, panels, doors and trunk covers to prevent high intensity and energy absorption during a collision.

- Secondly, the 23% powertrain consists of cast iron for the engine block. And machined carbon steel for the wear resistant gears.

- Thirdly, 12% in suspension ,use high strength rolled steel strip.

- Finally, the rest is located in the wheels, tires, fuel tanks, steering and braking systems.

Automotive Steel Products Trend

Advancements in production technologies mean the use of newer alloys of aluminium and magnesium has become more common. Plastics and composites, due to their lightweight and recyclable properties, are favoured by automotive companies. Hot rolled automotive steel is divided into automobiles beam steel, structural steel, compartment steel, wheel steel and pipe structural steel.

IBC’s products have been praised for their good cold working formability and ability to meet various processing requirements such as shearing, slitting, stamping, bending and roll welding. As one of the few enterprises in China able to stably produce and supply very thin and wide specifications, our limit specifications of 1.2mm * 1250mm, 2.0mm * 1610mm and 3.0mm * 1800mm for car compartments are perfect for lightweight commercial vehicle materials.

Conclusions

IBC (Tianjin) Industrial Co.,Ltd offers a variety of top-notch steel types, from hot and cold rolled to pickled & oiled to GI, AS and silicon steel. Furthermore, we provide special steels tailored to the automotive sector for an array of applications including automobile beam steel, wheels, anti-corrosion steel, camshafts, gearboxes, steering-gear, engine gear, crankshafts, connecting rods, universal joints, suspension springs, torsion bars, stabilizer bars, hubs, transmission bearings and leaf bearings.

Since the founding of IBC (Tianjin) Industrial Co.,Ltd, we have been following our mission of “Build the Future with Steel+”. To this end, we offer our customers an extensive selection of automotive steel coils and other top-quality steel products for their automotive needs. Our extensive partnerships with over 200 steel mills and various prestigious third-party quality control organizations guarantees that you can trust us to fulfill your requirements.

For more information on automotive grade sheet metal, contact IBC (Tianjin) Industrial Co.,Ltd.

Get In Touch With Us!