EN10111 DD13 Automotive Steel Manufacturer

IBC Metal Group produce EN10111 DD13 automotive steel for decades years. We export this product to all over the world. We work under EN10111 standard is stamping and cold forming steel. EN10111 is standard specification of continuously hot rolled low carbon steel sheet and strip for cold forming — Technical delivery conditions. Not only this specification, we have material of JIS, DIN as well.

Supply Range of DD13 Steel

Automotive steels are available in a variety of grades, each with specific characteristics that make them suitable for different applications. Some of the most common types of automotive steels include hot-rolled and cold-rolled steels, high-strength low-alloy (HSLA) steels, dual-phase (DP) steels, transformation-induced plasticity (TRIP) steels and martensitic steels.

Size we can provide:

- Thickness: 1.5mm-6mm;

- Width:700mm-1650mm.

As a professional DD13 steel work manufacturer, we can supply any specifications of DD13 steel structure according to your drawings.

Chemical composition of DD13 Steel Work

EN10111 DD13 automotive steel is a low carbon hot-rolled steel that conforms to EN 10111. It widely used in automobile manufacturing to produce structural parts that elongated to certain degrees. It is low intensity, good processing performance. For nonstructural presswork and forming, DD13 steel is ideal. For more information about DD13 steel structure Chemical composition and DD13 steel work Mechanical Properties, please see the following:

| Grade | C | Si | Mn | P | S | Alt |

|---|---|---|---|---|---|---|

| DD13 | ≤0.08 | ≤0.07 | ≤0.40 | ≤0.030 | ≤0.030 | ≥0.010 |

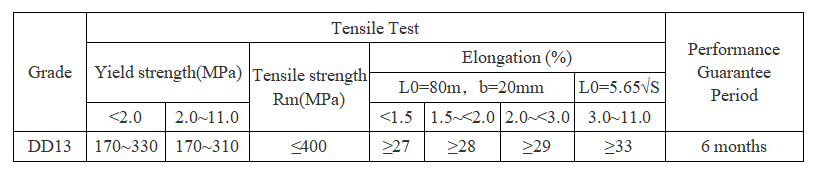

Mechanical Properties of DD13 Structure Steel

DD13 Steel Machining Parts Industry Application

EN10111 DD13 steel machining parts have a wide range of applications, from automotive and machinery, to lighting, furniture components and buildings. They are often used in the production of electrical cabinets and instrument cases as well as bicycle chains, rims, sleeve forks and motorbike frames – to name just a few. The majority of these parts are made from hot-rolled steel, galvanized or pickled before being cold-formed.

IBC Metal Group is Your Best Automotive Steel Suppliers

The automobile manufacturing industry relies heavily on cold rolled coil for the production of vehicle structures. Cold rolled steel plates measuring 0.5 – 1.5mm in thickness are largely used when constructing vehicle bodies, as they offer higher formability and design freedom than other soft non-alloy materials. Cold rolled steel coil is a staple material for the automotive industry, used for both body and structure components. Huaro’s wide range of cold and hot rolled coil steels can be tailored to meet various specifications such as JIS G3112 and DIN17102-83, while still having great welding, joining and painting suitability, plus providing added strength if desired.

Conclusion

IBC manufactures over 1,000 tons of EN10111 DD13 automotive steel a month. Our services include drilling, cutting, bending, welding, grooving, anti-correction and edge processing as well as spraying and assembly. Hot rolled steel and cold rolled steel have been essential in the automotive industry for many years; not only do our products meet increasingly stringent engineering requirements but they also offer competitive costs, superior resilience and variable strength levels. The product is ideal for necessary changes or rework too! Get in touch with us today if you require DD13 steel structures –we will provide you with top quality material.

Contact with IBC Metal Group Today!