Hot Work Tool Steel

Hot working tool steels are used in the hot-forming of work-pieces made of iron and non-ferrous metals as well as alloy derivatives at high temperatures. They are utilised in processes such as pressure die casting, continuous casting, extrusion and drop forging as well as in tube and glass manufacturing.

Application

| Shear blades / Sleeves | Die Casting / Plunger / Forging | Extrusion and Pressing Dies |

Cold Work Tool Steel

Cold working tool steels are high carbon steels that contain alloy additions of tungsten, manganese, chromium and molybdenum, which increase the hardenability of the steels.

The high carbon content produces adequate wear resistance for short run applications.

Applications

| Dies / Fuller | Fine Blanking | Cold Forming Dies | Profiling Rollers & Press Tools |

| Coining Dies / Thread Rolls | Stripper Plates | Pneumatic Tools | Thermo-Setting Resin Forming Dies |

| Punches / Chisels / Shear Blades | Brick Moulds | Trimming Dies | Phillips Head Forming Die |

Related Products

Plastic Mould Steel

Pre-hardened plastic mould steels are widely used for manufacturing mould for plastic because of their four main properties and characteristics:

- Wear Resistance; Corrosion Resistance; Mirror Finishability; Surface Workability

These steels are quenched and tempered before being manufactured into mould for plastic, therefore the deformation and cracking of mould resulted from heat treatment can be avoided.

- Plastic Mould Industry; Mould Frames; Machine Tool Engineering; Die Casting Industry; Mould Parts; Preform Dies

Machinery Steels

Machinery steels are carbon steels suitable for the working parts of the machine in general mechanical engineering industry. Different grades of steel can be applied to components with different level of stress and pressure ranging from moderate to high.All our machinery steel materials are hardened and tempered for oil quenching and water quenching. It is also suitable for flame hardening and induction hardening.

Application

| Axles / Gears | Driving gears | Eccentric shafts | Tool joints and drill collars (oil & gas industry) |

| Crankshafts | Shafts | Steering components | Short run punching and cutting tools |

| Pinions / Pins | Fasteners | Simple moulds | Base plates for mould and die |

| Arbours | Hand tools | Connecting rods | Hydrogenation vessels |

Abrasion-Resistant (AR) Steel Plate

Abrasion-Resistant (AR) steel plates have been developed specifically for long service life in harsh conditions. Designers and plant operators choose Abrasion-Resistant (AR) steel plates when striving to extend service life of critical components, and reduce the weight of each unit put into service. The benefits of employing Abrasion-Resistant (AR) steel plates in applications involving impact and/or sliding contact with abrasive material are immense.

General Applications:

- mining/quarrying; conveyors; material handling and construction; earthmoving

Please find the grades of Abrasion-Resistant (AR) steel plates we supply: AR 400; AR 500; ABREX 450; ABREX 500…..

Related Products

High Tensile Steel Plate

High strength high tensile steel plates are steels with low carbon content. This kind of carbon structural steel has very good tensile strength, good toughness, plasticity and processing property, and are widely used in structural assemblies where welding process is involved.

General Applications:

Piping; Pressure Vssels; Bridge Structures; Marine Structures; Structural assemblies (good weldability); Civilian Construction and Underground Engineering; Container Manufacturing; Automotive and Machine Mahufacturing.

ST52-3 steel is a structural steel that can be readily welded and it has the mechanical properties of 355 N/mm² for yield strength and 490 – 630 N/mm² for tensile strength respectively. It possesses excellent cold forming properties comparing to its low carbon equivalent. ST52-3 is equivalent to S355JR and S355J2. We supply two kinds of high strength high tensile steel, namely ST52-3 and Wel-Ten 780E.

Stainless Steel

Stainless steels provide an outstanding combination of high strength, good toughness, good corrosion resistance and good mechanical properties at high temperature (up to 600°F).

Application

| Shafts | Bolts | Petrochemical | Refrigerator Cabinet Panels |

| Sheets | Ribbons | Lashing Wire | Linings for Dish Washers |

| Wires | Tubes | Automotive Trim | Valve Components |

| Paper | Chemical | Element Supports | Food Processing |

| Fasteners | Aerospace | Chimney liners | Stove Trim Rings |

Cast Iron

Cast iron is a ferrous metals used in construction and outdoor ornament. It is hard, brittle, non-malle able (i.e. it cannot be bent, stretched or hammered into shape) and more fusible than steel. Cast ironisvery good in compression.

Characteristics:

- Free from sand marks and graphite marks; Good machinability due to its dense and even structure up to the deep centre of the material; Smooth casting surface and good precision.

Application

| Valves | Precision Instruments | Machine Tools and General Industrial Machineries |

| Cylinders | Metal Moulds | Automobile and Transportation Equipment |

| Pumps | Electrical Tools | Iron and Steel Work |

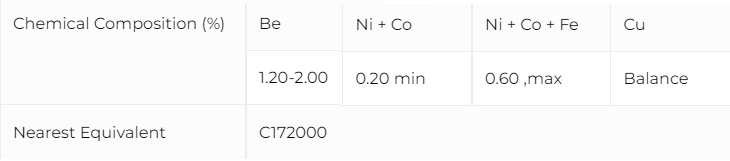

Beryllium Copper

NGK ULTRA is recognised as an excellent lower conductivity, higher hardness beryllium copper alloy for the plastic industry as injection moulds and tooling for blow moulds.

Due to its optimum combination of hardness, wear resistance, thermal fatigue, and thermal conductivity, it is known to produce superior quality plastic parts with minimum total production costs over other competing mould materials.

General Applications:

- Injection moulds & high pressure blow moulds; Inserts in steel moulds for higher cooling rates at critical areas; Inserts in aluminium moulds for higher strength & wear resistance; Cooling inserts; Nozzles & needles for hot runner systems

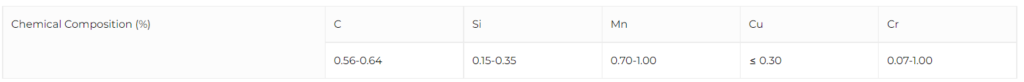

Spring Steel

SUP9A is a kind of hot-rolled alloy spring steel well suited for fabrication that requires shaping by blanking, bending, drawing, extrusion and swaging. It allows for closer dimensional tolerances and improved finishing.

General Applications:

Highly stressed; Quenched and tempered springs; Hand tools; Larger diameter coiled spring sand rock drilling studs in vehicle and tractor industries.

Contact with IBC Metal Group Today!