Galvanized Steel Coils – IBC Metal Group

We are an experienced manufacturing and trading company from China. Specialized in suppling all kinds of galvanized coils. Has served customers from 40+ countries, such as Canada, Turkey, Poland, Iran, Brazil, Ukraine, the Philippines, Malaysia, etc. Compared to famous galvanized steel coil manufacturers, IBC Metal Group offers a more competitive price for the same quality products.

Scope of Galvanized Steel Coils

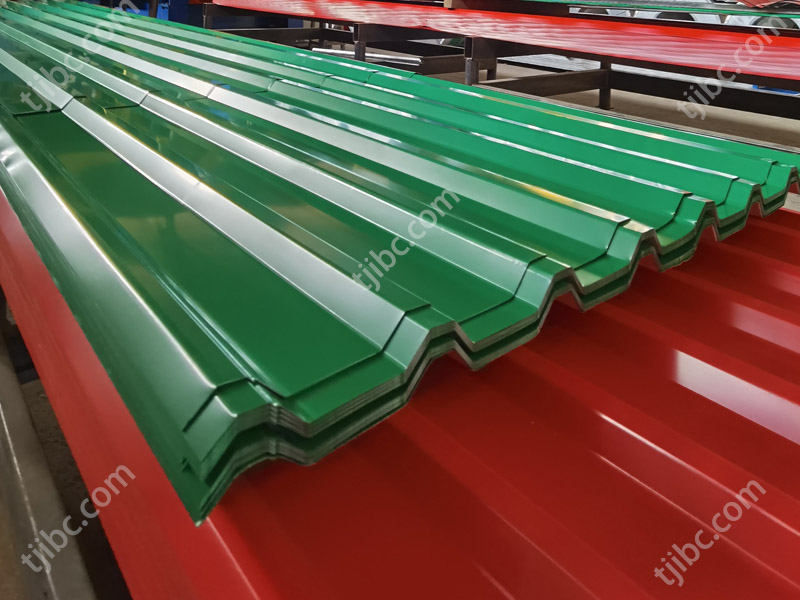

Galvanized Steel Coil is a special type of steel coil that has been hot dipped in a zinc coating. To protect it from corrosion and rust. And it gives the steel a shiny, smooth finish. Galvanized steel coils used in wide range of industries, including construction, automotive, solar and other applications where the steel will be exposed to weather or other elements.

| Width (mm): | 50mm ~ 1500mm |

| Thickness (mm): | 0.12 ~ 25mm |

| Zinc Coating (g/m2) | 20 ~ 275g/m2 |

| Coil Weight (Ton) : | 1.5 ~ 4 Tons |

| ID (mm): | 508mm/610mm |

Surface Treatment of GI Steel Coil

We supply all kinds of galvanized steel coils. You could choose the surface treatment of galvanized coils. We could manufacture according to your requirements.

| C = Chromic acid treatment | Good corrosion resistance, suitable for bare state |

| O = Oiled | Prevent rust during transportation and storage |

| P = Phosphoric acid treatment | A certain degree of corrosion resistance, good paint performance |

| U = Untreatment | Suitable for immediate painting |

You could choose combination among them. Or other methods according to your requirements. And the surfce quality level of galvanized coils we provided are FA, FB and FC. Most clients choolse FB and FC.

Hardness

Soft Hard (HRB60)

Medium Hard (HRB60-85)

Full Hard (HRB85-95)

What Are Key Standards of Glavanized Steel Coil?

The key standards are following for the production of galvanised coils include EN 10346 (Europe), ASTM A653 / A653M (US), DSTU EN 10346 (Ukraine), GOST 14918−80 (Russia and the CIS) and GOST R 52246−04 (Russia). Manufacturers also have their own original standards.

IBC Group offers galvanised steel coils with a thickness of 0.12 ~ 25mm and a width of up to 1500 mm for construction and machine building applications. Products manufacture in accordance with the requirements of key international standards (EN 10346, ASTM A653/A653M, GOST 14918, GOST R 52246).

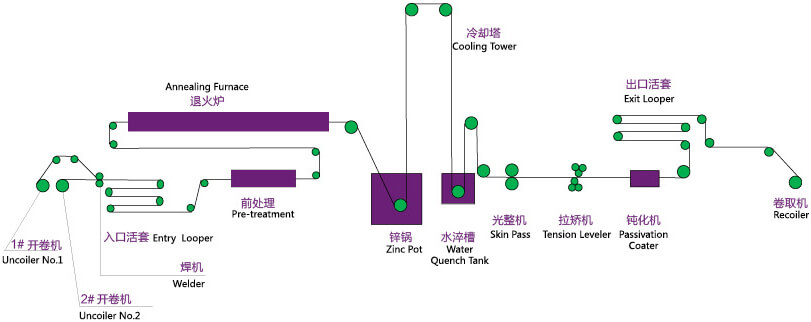

Manufacturing Process of Galvanized Steel Coil

The production and manufacturing process of galvanized steel coils can be divided into three steps: first step, the entire coil is pickled to remove rust and dirt. So that the surface of the galvanized steel strip can achieve a bright and clean effect. After pickling, pass ammonium chloride or zinc chloride, it is cleaned in an aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride. And then sent to the hot-dip plating tank for the galvanizing process; after the galvanizing process is completed, it can be put into storage and packaged.

The hot dip process includes passing the steel through a molten zinc bath, and the electro galvanizing process includes applying zinc through electrolytic treatment. As a result, the zinc layer is firmly adhered to the base metal through the iron-zinc bonding layer. So it is better than steel. That’s why we choose galvanized steel coils.

Galvanizing is one of the most effective and economical methods for protecting bare steel from corrosive environments. Zinc is not only a barrier between steel and the environment, but also sacrifices itself to protect the steel plate below. When two different metals are in contact and coupled with water and oxygen, sacrifice or current protection occurs. Zinc preferentially corrodes iron in steel. This protection prevents corrosion of the steel in areas not covered by zinc. Therefore, the diffusion of corrosion from cutting edges, drilling holes, etc. is minimized. So galvanized steel is good one to choose.

Contact with us!