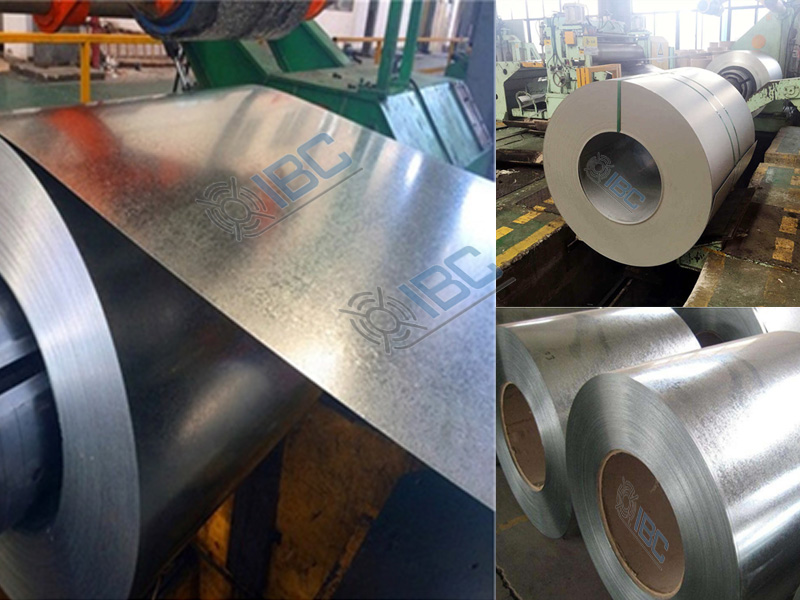

Galvanized Coil Manufacturer

IBC (Tianjin) Industrial Co., Ltd could supply all kinds of surface treatment of galvanized coil. No matter what kinds of galvanized coil do you need, please we could supply high quality with competitive price for your projects There are some different surface treatment of galvanized coil. All methods are to reduce the risk of corrosion during storage and transportation. Such as: Passivation; Oiling; Organic Coating Film; Phosphating, etc.

IBC Group could supply all kinds of treatments for the galvanized coils. No matter what kinds of requirements you need, please let us know.

Firstly, Surface Treatment of Galvanized Coil —— Passivation

The first surface treatment of galvanized coil is passivation. After passivation, it can reduce the rust (white rust) during the condition of wet storage and transportation. However, the corrosion resistance of this chemical treatment is limited and, moreover, passivation hinders the adhesion of most coatings. In general, other types of galvanized layer, except for zinc-iron alloy coating, will go through passivation treatment at the factory.

Secondly, It is Oiling

Oiling can reduce the corrosion of steel sheets or plates under wet conditions. And oiling the passivated steel plate and strip will further reduce the corrosion under wet storage condition. Please note that the oil layer should be able to removed with a degreaser that does not damage the zinc layer.

Thirdly, Surface Treatment of Galvanized Coil —— Organic Coating Film

Using a thin transparent organic coating film on the surface can provide additional corrosion protection, as well as fingerprint resistance. It can also serve as the adhesion for subsequent coating. An additional corrosion protection, especially fingerprint resistance, is provided by applying an extremely thin transparent organic coating film. Improving lubricity when forming, and as the adhesion bottom of the subsequent coating.

Fourthly, Phosphating

Phosphating treatment also is able to improve the adhesion and corrosion resistance of zinc coating. And coating without further treatment in addition to normal cleaning. Through phosphating treatment, the galvanized steel plate of various coating types can be coated without further treatment in addition to normal cleaning. This treatment can improve the adhesion and corrosion resistance of the coating and reduce the risk of corrosion during storage and transportation. After phosphating, we can use with suitable lubricant to improve the molding performance.

Non-Treatment

Plates and strips supplied in accordance with this standard may not be passivated or oiled or coated or coated or phosphating only if the orderer so requests and is responsible for such non-treatment.

If you have special requirements, please let us know.

- Mobile: +86-15222480985

- Tel: +86-22-27168866

- E-mail: [email protected]

Contact with IBC Metal Group Today!