IBC Group is one of the top PPGI Coils Manufacturer & suppliers in China. We are an experienced Manufacturing and trading company, which has served customers from 40+ countries, such as Canada, Turkey, Poland, Iran, Brazil, Ukraine, the Philippines, Malaysia, etc. Above 15 years experience in steel industry, IBC Group offers a more competitive price for the same quality products.

What is PPGI?

PPGI is pre-painted galvanized steel, also known as pre-coated steel, color coated steel etc. Using Hot Dip Galvanized Steel Coil as the substrate, PPGI is made by first going through surface pre-treatment. Then the coating of one or more layers of liquid coating by roll coating, and finally baking and cooling. PPGI coil is short for pre-painted galvanized steel coil. It uses a hot-dipped galvanized steel sheet as substrate and be coated with several layers of organic coatings to protect it from rusting.

Technical Standard for Prepainted Galvanized Coils:

| JIS G3302 | JIS G3313 | GB/T2518-88 | GB/T11253-9 |

| ASTM A755 | ASTM A513 | ASTM A780 | ASTM A653 |

Steel Grade for Prepainted GI Coils:

| Q195 | Q235 | Q345 | SGCC | SGCH |

| SGC340 | SGC400 | SGC440 | SGC490 | SGC570 |

| SGHC | SGH340 | SGH400 | SGH440 | SGH490 |

| SGH540 | DX51D | DX52D | DX53D | DX54D |

| DX55D | DX56D | DX57D | S220GD | S250GD |

| S280GD | S320GD | S350GD | S400GD | S500GD |

| S550GD | SS230 | SS250 | SS275 |

| Item | PPGI Coils |

|---|---|

| Substrate | PPGI, Prepainted Galvanized Steel Coil |

| Thickness | 0.12-2.5mm |

| Width | 600-1500mmor Customized |

| Coil Weight | 3-5 tons per coil |

| Zinc Coating Thickness | 20g/m2 to 275g/m2 |

| Colors | RAL Standard Color |

| Package | Standard export package or customized |

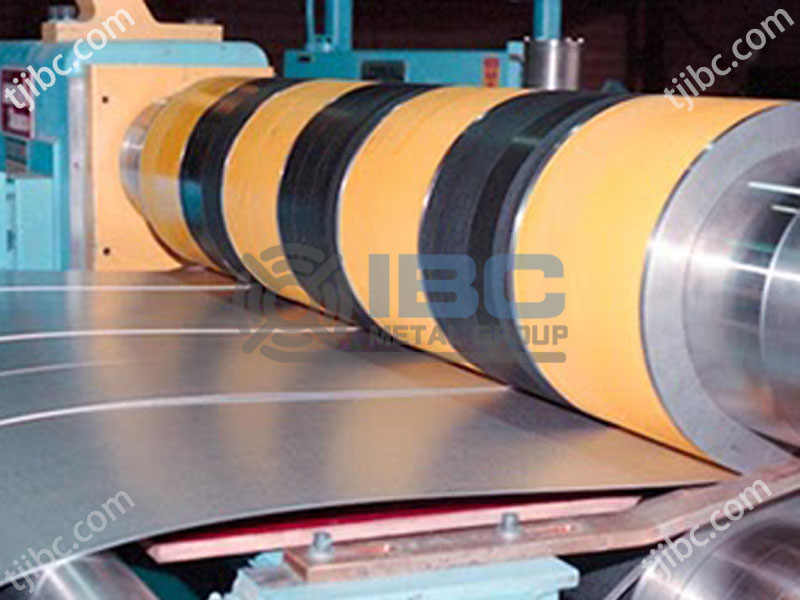

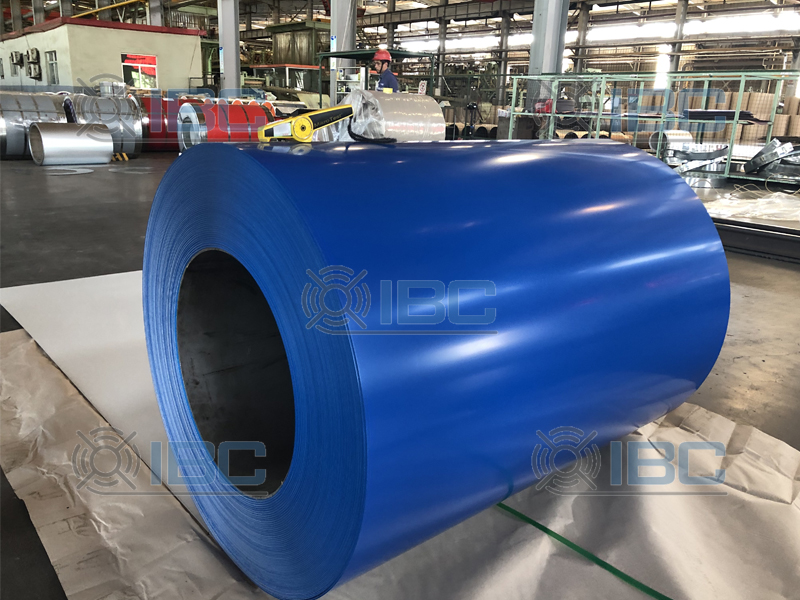

PPGI Coils Factory

IBC Group is specializing in the production of galvanized and color coated steel coils and sheets. And how to decide coating for PPGI coils is very important. The factory covers an area of 160,000 square meters. There are 2 color coated lines, a pickling line,c old rolling lines, 2 galvanizing lines, etc.

It is able to produce PPGI coils with 0.14-1.2 mm in thickness, 600-1,250 mm in width. And the annual production capacity of PPGI coil is 120,000 tons. Also, we have professional equipment to make corrugated steel sheets, PPGI plain sheets, and strips. You could see the whole PPGI Manufacturing Process in our factory.

Coatings for PPGI Coil

There are four basis coating types for PPGI Coils. When choosing a primer, you need to consider the adhesion of the primer; while for top coating, corrosion resistance and color retention will be more important. There are four commonly-used coatings, including polyester (PE), silicone modified polyester (SMP), high durability polyester (HDP), and polyvinylidene fluoride (PVDF).

PE Coatings

SMP Coating

HDP Coating

PVDF Coating

PE coating is of good adhesion, which is widely used as a primer. While HDP and PVDF will be more suitable as a top coating because of their excellent durability and color retention. And you could see How to Decide Coating for PPGI Coil to learn more about this.

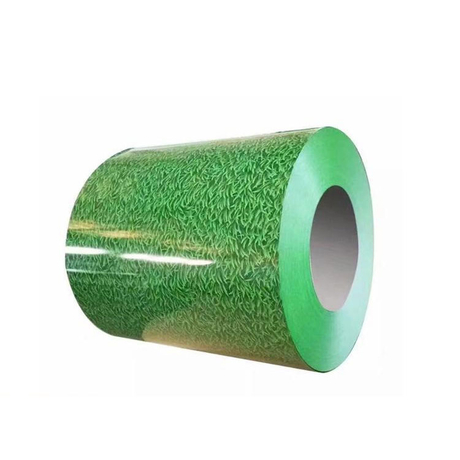

Colors of PPGI Coils

Colors of prepainted galvanized steel coils include sky blue, grey, silver, traffic red, moss green, olive green, leaf green, etc. Our printing patterns include flower, wood grain, marble, brick, as well as custom patterns. To customize your own PPGI coated coil, please send a RAL color code or pattern or a sample. Depending on the coating materials, light, etc., the actual color may differ slightly. However, we promise to use the paint as agreed.

Why We Choose PPGI Coated Coil?

There are various colors and patterns of PPGI coils to meet different styles and uses. The colorful coatings also make PPGI steel more corrosion-resistant and long-lasting. PPGI steel coil has great processing performance. So you can make coils into different products according to your need. Prepainted galvanized steel coil also keeps the strength of steel, which makes it tough and safe. PPGI coated coil is light in weight so that it is easy to transport and install. Compared to PPGL steel, it is more affordable.

Applications of PPGI Coils

We could find PPGI in a variety of applications, including construction industry (e.g. roofing, interior and exterior wall panel, balcony surfaces, ceilings, partitioned walls, windows and doors), transportation (e.g. car body parts, ship and train decks and containers), electrical equipment (primarily used to make shells of fridges, washing machines and air conditioning systems) as well as furniture pieces (e.g. wardrobes, lockers, radiators, lampshades tables, beds and bookshelves). Furthermore, it’s also frequently used in other industries such as roller shutter production and manufacture of advertising boards, traffic signboards and elevators or whiteboards.

IBC Group could supply PPGI/PPGL coils for you. Of course, we have galvanized steel coils as well. It is available in big, regular, small, and zero spangles. Thickness from 0.12mm-2mm; Width from 600mm-2,000mm; Coil weight from 3 ~ 5 tons; And Zinc Layer Thickness from 30g to 275g per square meter.

We have other products as well for your one-stop station. Contact with us form more information!

Contact with us!