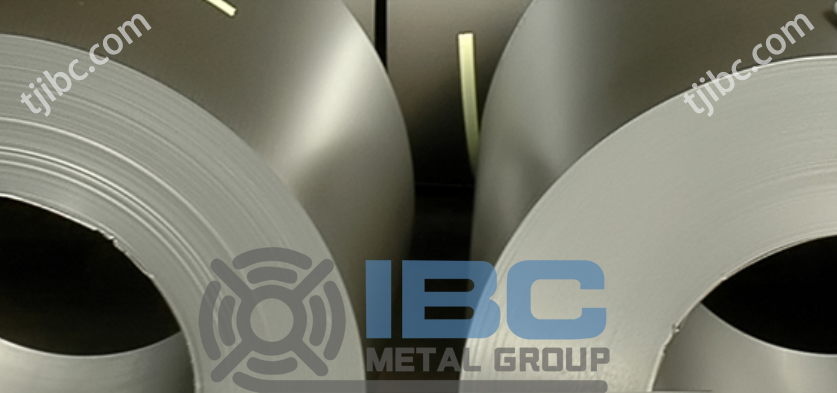

Aluminized Steel Manufactured

IBC Group, the leading steel coils and pipes supplier. We supply high quality product with competitive price. You can trust us to do what we say because our reputation proves it. With fifty years in business, we have positioned ourselves as experts in flat-roll steel processing while exceeding our customers’ expectations. We’d love the opportunity to earn your trust!

What is Aluminized Steel?

Aluminized Steel: Combining the power of aluminum and steel for a better material. To make aluminized steel, you need to mix iron with aluminum. This process involves the clean steel being dipped into a vat of molten aluminum that is mixed with a little silicone. This dipping process happens three times in total and left to air dry, which results in an iron core with three layers of aluminum.

Both aluminum and steel are ideal manufacturing materials; aluminum boasts extreme resistance to corrosion, while steel is notable for its superior strength. They both have weaknesses, however. For instance, carbon steel does not have enough chromium to create an oxide layer that would protect it from rust. Meanwhile, pure aluminum is much weaker than steel. Metallurgists combined the two to produce a better compound material — aluminized steel.

If you want the complete list of aluminized steel’s physical and chemical properties, IBC (Tianjin) Industrial Co.,Ltd will be happy to share it with you. For now, let’s explore the main characteristics of this material.

Aluminized Steel’s Properties

AL steel is carbon steel that has been coated with an aluminum-silicon alloy through a process called hot-dipping. The technique creates a tight metallurgical bond between the base metal (the carbon steel) and its alloy coating to give the new material a combination of steel and aluminum’s best characteristics.

Aluminized steel has steel’s strength while also maintaining aluminum’s advantageous surface qualities. It also has good formability, too, so metallurgists can bend, fold, corrugate, and roll it without breaking.

First one, High Temperature Resistance – the aluminum-silicon coating of aluminized steel makes the material resistant to high temperatures. In fact, it can withstand up to 900° F, much higher than galvanized steel’s limit of 392° F.

Second one, Low Thermal Expansion Coefficient – Aluminized steel has a relatively lower thermal expansion coefficient, which means it’s less likely to deform under heat stress. This is its advantage over stainless steel.

Third one, Corrosion Resistance – Aluminized steel is more corrosion-resistant than both carbon steel and aluminum because the aluminum oxide that forms during hot-dipping protects the base metal.

Aluminized steel is relatively new in the industry, but it has already become a material of choice for its unique set of properties. Additionally, it’s more economical than common materials like stainless steel.

Is Aluminized Steel Different From Stainless Steel?

The answer is definitely yes. There are a few differences between aluminized steel and stainless steel. Although both can be used in the kitchen environment, most commercial premises use stainless steel for their surfaces and splash guards.

Firstly, We See it From Composition

Al-zed doesn’t have the same aesthetics as stainless steel, which is why most kitchens use stainless steel. There are two types of AL steel, one coated in silicone for cookware, and the other pure aluminum for heat and corrosion resistance.

Stainless steel comes in three forms: ① Ferritic Grades – Contains chromium and carbon; ② Martensitic Grades – Contains more than 0.1 percent carbon and chromium; ③ Austenitic Grades – Containing at least 10 percent nickel

The last grade is the best quality stainless steel and is therefore perfect for cooking environments. This is because it has the best anti-corrosion properties and is mouldable, so can be turned into tables and kitchen guards.

Secondly, Thermal Conductivity

Alu-zed steel has the advantage over stainless steel in this department, which is why it is the preferred metal for exhausts. It handles heat much more effectively than stainless steel, which can deform if it gets too hot.

Thirdly, Strength

Stainless steel is the winner in this respect. Because of its composition, it has great anti-corrosion and anti-rust properties. Aluminized steel has an outer oxidized layer that protects the material. If this outer coating is damaged, then it can start to rust.

Finally, Cost

Because of its low production costs, AL steel is cheaper than stainless steel. However, stainless steel is used more in cooking because it lasts longer despite the increased cost.

Capabilities of IBC Group

- Gauge: 0.46 ~ 2.34 mm

- Width: 921mm ~ 1651mm

- Coating Weights: T1-13; T1-20; T1-25; T1-40; T1-60; (oz/ft2); AS80 (40 – 40g/m2 ); AS150 (70 – 70g/m2)

- Specification: ASTM A463 (Type A/B/C/DDS/EDDS)

Related Resources

Contact With us!