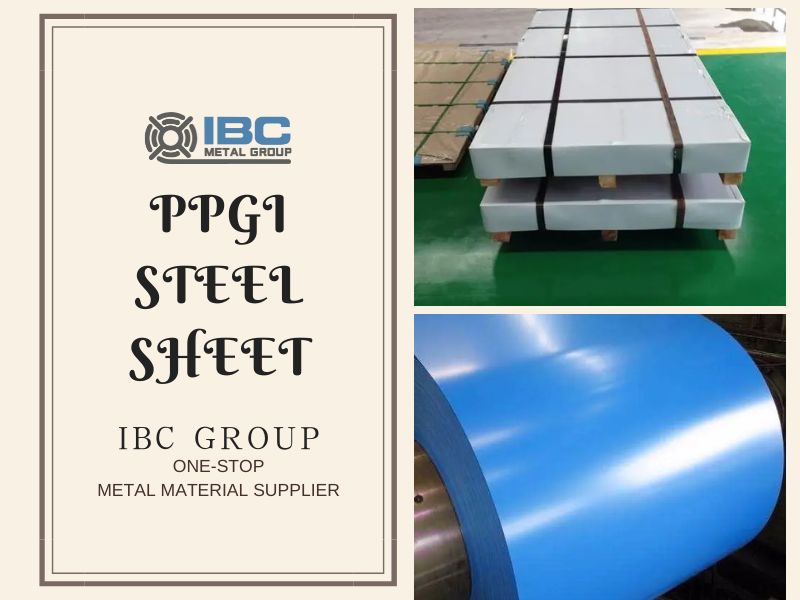

PPGI steel sheet is the coated steel plate (such as galvanized, aluminized zinc, nickel plating, etc.) surface chemical treatment (such as degreasing, phosphating, chromic acid passivation), and then coated with paint, and then baked products. It has good anti-rust performance and beautiful appearance, common colors are red, blue, white, gray and so on. It is usually used in building wall panels, roofs, warehouses, shopping malls and other fields.

Performance Profile

1. Weather resistance: PPGI steel sheet has excellent weather resistance, which means that it can resist various climatic conditions, including wind and rain, ultraviolet radiation, etc., without fading or aging easily.

2. Corrosion resistance: The surface of the color steel plate is coated with one or more layers of organic coatings, such as PE, SMP, HDP, PVDF, etc. It can effectively prevent metal corrosion and oxidation, thereby extending its service life.

3. Decorative: This steel plate has bright appearance, rich color, good decorative performance, and can add beautiful and generous appearance to buildings and home appliances.

4. Sound insulation and heat insulation: It also has good sound insulation performance, which can provide a comfortable indoor environment for the building.

Advantages of PPGI Steel Sheet

1. Wide range of application: It is widely used in construction manufacturing, home appliances and transportation and other fields. Its excellent performance and variety of color choices make it able to meet the needs of different fields and projects.

2. High cost performance: The price of color steel plate is relatively low, and it has good performance, so it has a high cost performance. This makes it ideal for many projects, especially if the budget is limited.

3. Easy processing and installation: This steel plate is relatively light and easy to carry and install. In addition, it can also perform machining operations such as cutting, bending and welding as needed to adapt to different application scenarios.

Matters Need Attention

1. Material preparation and inspection

Before operation, ensure that the quality of the steel plate meets the requirements of the project and check its surface for scratches, dents or other damage.

Check whether the coating of the steel plate is uniform, and there is no peeling or foaming phenomenon.

2. Storage and protection

This steel plate should be stored in a dry, ventilated environment to avoid long-term exposure to moisture or chemicals.

Avoid contact with sharp objects to avoid scratching the coating.

3. Cutting and processing

Use a suitable cutting tool to make sure the incision is smooth to avoid excessive damage to the coating.

In the processing process, care should be taken to avoid excessive heat, so as not to damage the coating.

4. Installation and fixing

When installing PPGI Steel Sheet, ensure that the joints between the plates are tight to avoid excessive gaps.

Use suitable fasteners for fixing to ensure that the steel plate is firmly fixed and not easy to loose.

5. Protection and maintenance

After the installation is completed, the steel plate should be checked regularly and the damaged part of the coating should be repaired in time to prevent rust.

Regular cleaning to avoid long-term adhesion of dirt on the surface of the steel plate, affecting the appearance and service life.

6. Safety precautions

During operation, wear appropriate protective equipment, such as gloves and safety shoes, to avoid injury.

Pay attention to fire safety to avoid sparks or high temperature during operation, which may cause fire.

Contact with us today!