Advantages In Material Properties

1. High strength: The strength of cold drawn round bar is higher than that of ordinary steel, which means that it can withstand greater pressure and weight without sacrificing weight or size. This advantage is particularly important in applications that require high loads, such as building supports, Bridges and mechanical components.

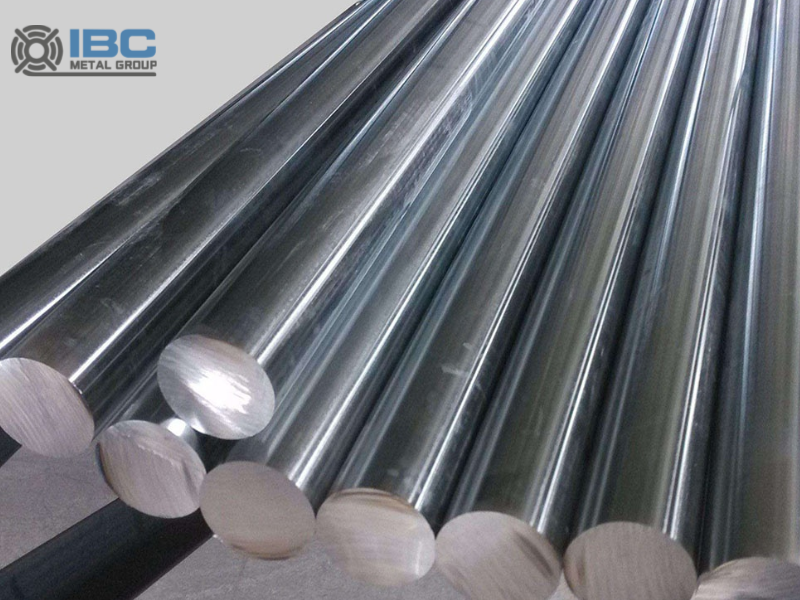

2. Wear resistance and corrosion resistance: Its surface is smooth and not easy to damage, so it has good wear resistance. At the same time, the chemically treated and coated round steel also has good corrosion resistance. And it can be used in harsh environments for a long time.

3. Good processing performance: This steel has good processing performance and can be processed and formed in various ways, such as cold drawing, cold rolling, cold drawing, cold bending, etc., so as to meet the needs of different fields. This makes it an ideal material for various manufacturing and construction industries.

4. Light weight: compared with ordinary steel, it has lower density and lighter weight. This advantage is particularly important in areas that require weight reduction, such as automotive, aviation and other industries.

Advantages of Operational Process

1. High precision: in the production process of cold drawn round bar, through multiple drawing operations, the cross-sectional area of the steel can be gradually reduced, while increasing its length. This process enables high precision control, making the size and shape of the round steel more accurate to meet the needs of a variety of complex applications.

2. High production efficiency: its production process can be automated and continuous, thus greatly improving production efficiency. In addition, due to its good processing performance, various processing and molding can be carried out in the production process, further improving the production efficiency.

3. Environmental protection and energy saving: Its production process does not require high temperature heating. So it is more environmentally friendly and energy saving than the traditional hot rolling process. This helps to reduce energy consumption and exhaust emissions, reducing the negative impact on the environment.

Cold Drawn Round Bar Operation Precautions

1. Strictly abide by the operating procedures: When operating the steel, it is necessary to strictly abide by the operating procedures to ensure the safe and stable operation of the equipment. It is forbidden to adjust device parameters without permission or perform unauthorized operations.

2. Ensure the safety of the working environment: the factory needs to ensure the safety of the working area, remove debris and debris, and prevent accidents. At the same time, the staff need to wear the necessary safety protective equipment, such as hard hats, safety shoes, safety goggles, etc.

3. Regular maintenance of equipment: In order to ensure that its production process can be carried out stably, it is necessary to regularly maintain and maintain the equipment. This includes the cleaning, lubrication, fastening and other work of the equipment to ensure the normal operation of the equipment and extend the service life of the equipment.

Contact with us today!