Material Characteristics

High strength: AH32, AH36, DH36 Shipbuilding Steel Plate has high yield strength and tensile strength, and can withstand various loads encountered by ships during navigation, including wind waves, cargo weight and so on.

Good toughness: the steel plate can still maintain good impact toughness at low temperatures to ensure the safe operation of the ship in cold waters.

Good weldability: This kind of steel plate has good weldability. It is easy to carry out welding operations during ship construction, while ensuring the quality of welded joints.

Corrosion resistance: Although it is not a specialized corrosion resistant steel itself, its ability to resist seawater corrosion can be improved by proper surface treatment (such as painting, hot dip galvanizing, etc.).

Production Process of Shipbuilding Steel Plate

Steelmaking: The use of converter or electric furnace for initial refining, then through the LF furnace for refining. And then through the VD furnace for vacuum degassing treatment to obtain high-quality molten steel.

Continuous casting/die casting: The refined molten steel is injected into the continuous casting machine or die casting mold for molding to form a preliminary steel plate blank.

Cleaning and heating: cleaning and heating the surface of the steel plate blank to eliminate stress and improve rolling performance.

Rolling: The heated steel plate blank is rolled to obtain the desired thickness and size.

Inspection and heat treatment: non-destructive inspection of the rolled steel plate to ensure its internal quality. And according to the need for heat treatment to improve its mechanical properties and corrosion resistance.

Surface inspection and finishing: Surface inspection of the steel plate after heat treatment to ensure its surface quality. The factory will perform surface finishing and coating treatment on qualified steel plates to meet customer requirements.

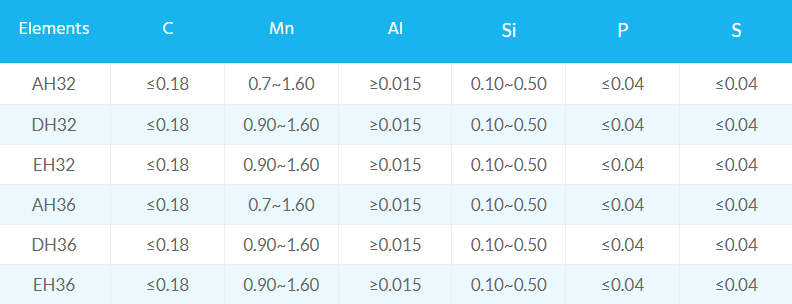

Chemical And Mechanical Requirements of Shipbuilding Steel Plate

Contact with us today!