The Main Considerations For Selecting Green Steel

The selection of green steel needs to comprehensively consider the green production evaluation requirements of steel, green application requirements of steel and innovative technology requirements. At the same time, we should also follow the principle of full life cycle, sustainable development and operability.

1. Resource attributes

The production process of steel involves the consumption and utilization of a lot of resources. In particular, it involves longer processes, including saving management, full utilization and cost control of ferroalloy, steel scrap, coal, water and other resources. This has a great impact on reducing the consumption of ton steel resources and improving production capacity.

2. Energy attributes

Steel is not only a high energy consumption industry, but also produces high value-added by-products in the main process. For example, the coking process of coke oven gas, an average of a ton of coke about 400m3 coke oven gas, its calorific value of 17~19MJ/m3. The calorific value of coke oven gas is about half that of natural gas. Although the calorific value of blast furnace gas is lower than that of coke oven gas, the output of blast furnace process is larger. For example, the comprehensive coke ratio of 450kg/t hot metal blast furnace process, blast furnace gas output is about 1575m3. This can realize the gas supply to the whole plant and be used for gas power generation.

3. Application of innovative technology

With the continuous improvement of science and technology level of iron and steel industry, the improvement of industrial technology and equipment level and the continuous improvement of quality system, the product structure of the industry has also been constantly optimized.

Therefore, the quality of products has also been greatly improved. However, the direction of scientific and technological innovation of iron and steel industry will continue to take green and intelligent as the core theme. Factories should target key weaknesses.

Green Steel Selection Management Evaluation Index System

| Green Steel | Level 1 Indicator | Level 2 Indicator | Wt | Total Wt |

| Green production evaluation indicator | resource attribute | Alloy saving technology and management | 0.03 | 0.14 |

| water-saving technology and management | 0.03 | |||

| comprehensive utilization of solid waste | 0.02 | |||

| scrap to steel ratio | 0.03 | |||

| water recycling | 0.03 | |||

| Energyattribute | Energy recovery rate | 0.02 | 0.16 | |

| energy generation | 0.03 | |||

| comprehensive energy consumption | 0.08 | |||

| gas recovery and utilization | 0.03 | |||

| environmental attribute | global warming trend | 0.10 | 0.20 | |

| air pollutant emissions | 0.05 | |||

| comprehensive utilization of solid waste | 0.05 | |||

| Application of innovative technology | low-carbon technology application | 0.05 | 0.05 | |

| Green application evaluation indicator | product attribute | Meet product standards | 0.10 | 0.10 |

| Management attribute | green supply chain management | 0.10 | 0.10 | |

| Quality, environment and energy system certification | 0.10 | 0.30 | ||

| Life cycle/carbon footprint assessment | 0.10 | |||

| green product certification | 0.10 |

Computational Formula

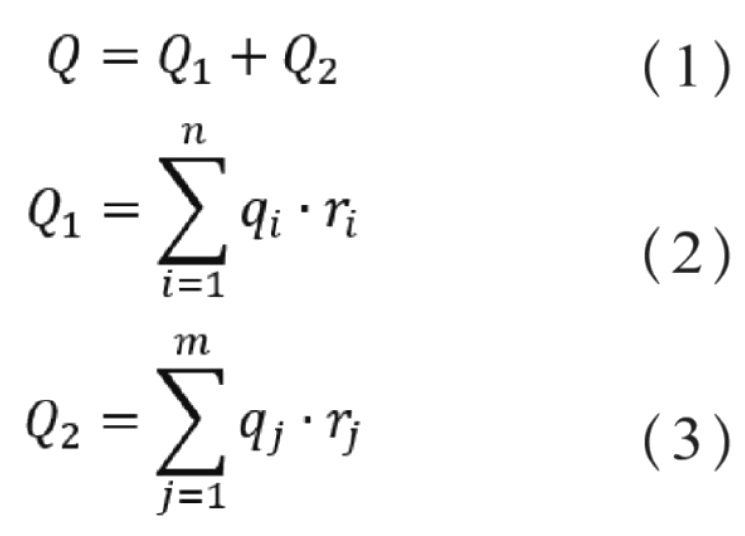

Through the evaluation of each index, and according to the following equations to determine the final score:

Q——total score;

Q1——Total score of green production evaluation indicators;

Q2——Total score of green application evaluation indicators;

qi——Score of each indicator of green production;

Ri——Weight of each indicator of green production;

Qj——Score of each indicator of green application;

Rj——Weight of each indicator of green application.

The grade division of green steel selection management is determined by the total score of evaluation Q. It is divided into excellent, qualified and general according to the score, as shown in the following table:

| Grade | Excellent | Qualified | Everage |

| Q | Q≥85 | 60≤Q<85 | Q<60 |

Under the background of the increasing demand for green steel in downstream enterprises, the comparison and selection of steel has gradually become the development trend of enterprise procurement.

This paper establishes a method for evaluating and selecting green steel. Including important evaluation indicators of green supply chain management, from the perspective of green production management and sustainable development of enterprises, it comprehensively, scientifically and feasibly contributes to green steel selection and green development of the industry.

Contact with us today!