Product Features And Manufacturing Process

Product Features of Seamless Alloy Steel Tube

1. High precision: The size accuracy and shape accuracy of this steel pipe are very high, which can meet the requirements of various high precision application scenarios.

2. High strength: due to the use of high-quality alloy materials, it has high strength and can withstand greater pressure and impact force.

3. Corrosion resistance: the addition of alloy elements makes the steel pipe have good corrosion resistance. It can be used in a variety of harsh environments for a long time.

4. Good processing performance: it has good processability, can be cutting, bending, welding and other processing operations.

Manufacturing Process

1. Raw material preparation

· Material selection: according to the required steel pipe performance requirements (such as strength, corrosion resistance, high temperature resistance, etc.), select suitable alloy materials. These materials may include stainless steel, nickel-based alloys, titanium alloys, superalloys, etc.

· Smelting and casting: the selected alloy raw materials are smelted, and alloy ingots or billets that meet the requirements are obtained by adjusting the composition and process parameters.

2. Billet processing

· Heating and perforation: The worker will heat the alloy blank to the appropriate temperature. And then use a punch to punch to form a preliminary tube blank. Perforation methods may include hot rolling perforation, diagonal rolling perforation or tube jacking perforation.

· Pickling and passivation: pickling the perforated tube blank. The surface is removed of oxide scale and dirt and then passivated to improve its corrosion resistance.

3. Hot rolling and cold rolling

· Hot rolling: the tube billet is heated to a certain temperature in the heating furnace. And then rolled through the hot rolling unit, gradually reducing the pipe diameter and increasing the wall thickness until the desired size is reached. In hot rolling process, it is necessary to strictly control the temperature and rolling force to ensure the quality of pipe.

· Cold rolling: for seamless alloy steel tubes requiring higher precision and surface quality, cold rolling process can be used. Cold rolling is carried out at room temperature. The dimensional accuracy and surface quality of pipe can be improved by reducing pipe diameter and wall thickness gradually through multi-pass rolling.

4. Heat treatment

· Solution treatment: hot rolled or cold rolled steel pipes are treated with solution treatment to eliminate stress, homogenize structure and improve performance. This treatment usually includes steps such as heating, insulation and cooling.

· Aging treatment: For some alloys, such as superalloys and titanium alloys, factories need to age them to further improve their strength and stability. Aging treatment refers to holding at a certain temperature for a period of time, followed by natural cooling or rapid cooling to room temperature.

5. Test and cut

· Non-destructive testing: Conduct non-destructive testing on the steel pipe, such as ultrasonic testing, ray testing, etc., to detect whether there are defects inside the pipe.

· Size and appearance inspection: Check the size, wall thickness and appearance of the pipe. It can ensure that it meets the design requirements.

· Cutting and packaging: According to customer requirements, steel pipes are cut to the required length, and packaged and marked for transportation and storage.

Specification of Seamless Alloy Steel Tube

| Dimension | 6 mm – 1080 mm |

| Thickness | 1mm – 135 mm |

| Length | 3 m – 12 m or according to the requirements of clients |

| Standard | ASTM GB DIN |

| Steel grade | A106/53/179/214/192/210 A/B/CST37.2/35.4/35.8/52/52.3/52.4/42/45 10# 20# 45# P2, P12, P11, P22, P5, P9, P91 T2, T11,T5,T9,T22, 4140, 12CrMo, 15CrMo, 12Cr2Mo, 1Cr5Mo, 2CrMo4, 1Cr9Mo, 10CrMo910, etc. |

| Payment terms | T/T, L/C |

| Delivery port | Tianjin, China |

| Delivery time | 10 or according to the real quantity of the tubes |

| Surface treatment | Black painting Varnish painting 3PE Hot galvanized Bare tubeor other coating according to your requirements |

| End of Tubes | Beveled, plain, thread, plastic caps |

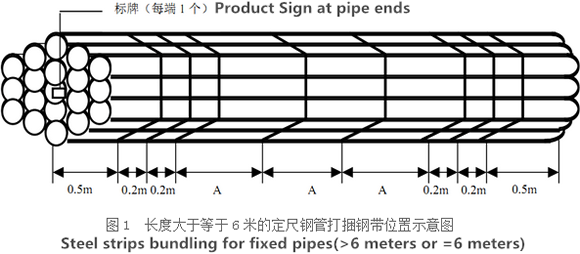

| Package | Bundles, lossen or according to your requirements |

| Certificate | API 5L/5CT, ISO, PED etc. |

Application of Seamless Alloy Steel Tube

1. Oil and gas industry

·Extraction and transportation: seamless alloy steel tube is used for connecting equipment in oil and gas extraction Wells, transmission pipelines and refineries. Due to its high strength and corrosion resistance, it can ensure stable operation in high pressure, high temperature and corrosive environment.

·Downhole tools: Used to manufacture drilling tools and casing to cope with complex geological conditions.

2. Chemical industry

·Process Flow: This alloy tube enables the manufacture of reaction kettles, distillation towers, heat exchangers and conveying pipes during the production, storage and transportation of chemicals, ensuring the purity and safety of chemicals.

·Corrosion resistant equipment: Manufacture corrosion resistant equipment such as storage tanks, pipes, etc. to cope with the erosion of corrosive chemicals.

3. Power industry

·Boilers and superheaters: Manufacture boiler and superheater water walls, superheater tubes, and reheater tubes to ensure steam circulation at high temperature and pressure.

·Power generation equipment: manufactures piping for cooling systems of steam turbines and generators to ensure the stable operation of equipment.

4. Aerospace

·Aircraft structure: the supports and connections of an aircraft structure, such as the skeleton of the wings, fuselage, and tail.

·Fuel system: Manufacture of fuel pipelines and tanks to ensure a steady supply and safety of fuel.

5. Automobile industry

·Exhaust system: The exhaust system of an automobile, such as the exhaust pipe and catalytic converter.

·Structural parts: Structural parts of an automobile, such as chassis, suspension, and steering systems.

6. Shipbuilding

·Hull structure: Used for supporting and connecting hull structures such as keels, ribs, and decks.

·Piping system: the ship’s fuel oil, fresh water, fire and drainage piping system.

Why Partner with IBC Group?

With a legacy of excellence and a dedication to customer satisfaction, we are your go-to source for premium seamless alloy steel tubes. Our expertise and commitment ensure that you receive top-quality products that perform reliably in any application.

Contact with us today!