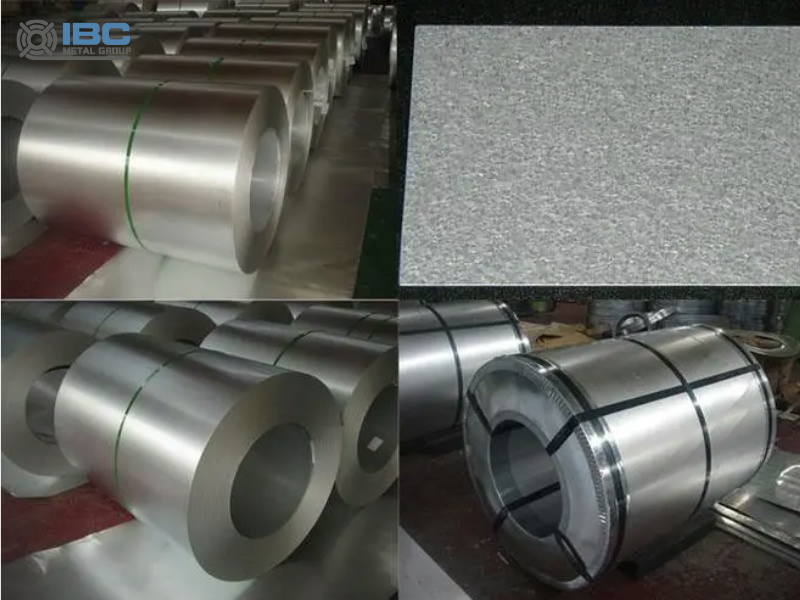

Advantages of Aluminized Steel

- Good corrosion resistance

Aluminum coating can effectively isolate steel from the external environment, especially to prevent direct contact with water, oxygen and chemical substances. This greatly enhances the corrosion resistance of the steel. The corrosion resistance of aluminized steel is particularly outstanding in humid, acid-alkali and other harsh environments.

- High heat reflectivity

Aluminum has good thermal conductivity and reflection. So its thermal reflectivity in the sunlight or high temperature environment is much higher than that of ordinary steel. It is particularly important for the energy-saving design of building roofs, external walls and other parts.

- Beautiful and easy to process

The aluminum coating can make the steel surface show a metallic luster and improve the overall beauty. At the same time, this kind of steel is almost the same as ordinary steel in processing, cutting, welding, etc. And it is easy to achieve a variety of complex structures and shapes.

- Environmental protection and sustainability

Aluminum is a recyclable metal, so this steel can be recycled at the end of its useful life, reducing its environmental impact. In addition, compared with other anticorrosive coating materials, its production process produces fewer pollutants and is more in line with environmental requirements.

- Cost effective

Its initial investment cost may be slightly higher than that of ordinary steel. However, due to its corrosion resistance, long life and energy saving performance, from the perspective of long-term use, its comprehensive cost effectiveness is better than ordinary steel.

Applications of Aluminized Steel

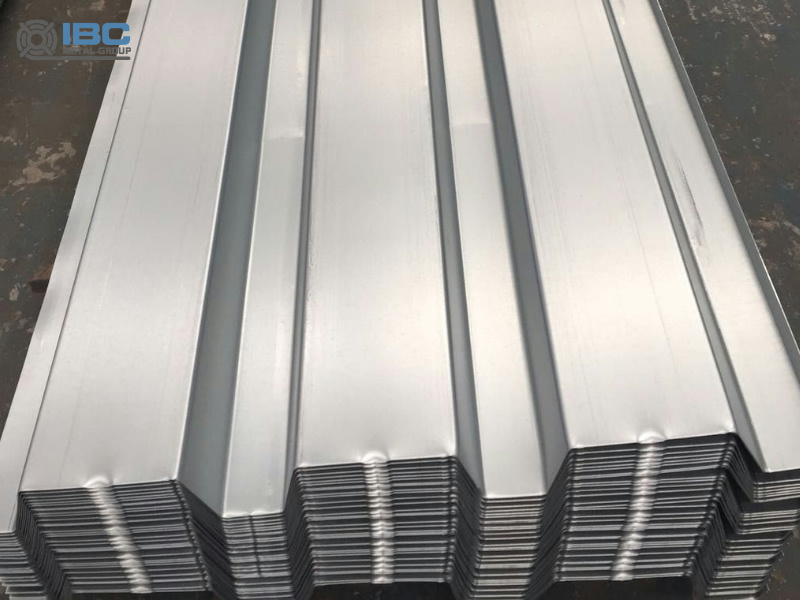

- Architectural field

In the construction industry, this steel is widely used in the manufacture of building structures, interior and exterior wall panels, roof panels and so on because of its excellent corrosion resistance and strength characteristics. Its environmental performance also meets the requirements of modern construction industry for sustainable development, so it has broad application prospects.

- Home appliance industry

In home appliances, aluminized steel is often used to make metal parts of household appliances such as washing machines and refrigerators. Its good processing properties, high strength and hardness make the durability and performance of household appliances significantly improved.

- Automobile manufacturing

In the field of automobile manufacturing, its application is also very important. It can be used to manufacture various parts of automobiles, such as frames, carriages and so on. Because of its high strength and good corrosion resistance, it can effectively extend the service life of auto parts. This can improve the overall performance of the car.

- Other fields

In addition to the above fields, it is also used in electronic equipment, thermal equipment, agricultural and mining machinery, gas and fuel products and other fields. For example, it can be used to make metal casings for electronic devices, improving the stability and durability of the devices. In thermal equipment, its good heat resistance enables the equipment to operate stably in high temperature environments.

Operation Cautions

Device check and maintenance: Before performing operations, check and maintain related devices to ensure the normal running and stability of the devices and prevent operation interruption or security problems caused by device faults.

Control current stability: During the operation of aluminized steel, special attention should be paid to the stability of the control current. Too much or too little current can lead to substandard coating quality, so it is necessary to ensure that the current is within the appropriate range and remains stable.

Follow the operating specifications: strictly follow the operating specifications for steel operation, do not change the operating process or parameters at will. For uncertain operation steps or problems, consult a professional or consult the relevant operation manual in time.

Pay attention to the working environment: keep the operating environment clean and clean to avoid debris or dust to pollute the steel. At the same time, ensure that ventilation is good to prevent harmful gases or steam buildup.

Emergency handling: In the process of operation, if an emergency situation or safety accident occurs, stop the operation immediately and take appropriate emergency handling measures to ensure personnel safety and prevent the expansion of the accident.

Contact with us today!