Product Detail

The performance of API 5L Line Pipes are mainly reflected in its high strength, good toughness and corrosion resistance. The pipe strength level can be up to X100Q/L690Q. This high strength characteristic makes it able to withstand conveying tasks in high pressure environments. At the same time, the toughness of the pipeline also ensures stable operation in extreme environments, such as low temperatures or high pressures. In addition, by adding specific alloying elements and using heat treatment technology, API 5L pipes also show good corrosion resistance and can operate stably in corrosive media for a long time.

Thickness: 8mm-60mm, Width: 1500mm-4020mm, Length:3000mm-18000mm.

Delivery state: Normalizing rolling, Quenched and tempered.

End types: bevel end,plain end, threaded end. Plastic Cap or Iron protector.

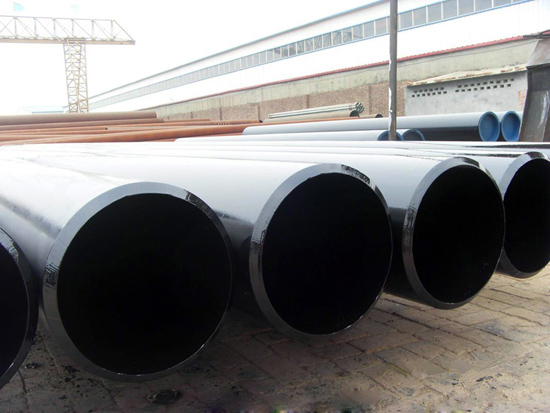

Surface Treatment: bare pipe;varnish painting;Oil painting;3PP,3PE,FBE,Epoxy Coating.

Steel Grade: Grade X42,Grade X42,Grade X52,Grade X60,Grade X70

Classification of API 5L Line Pipes

1. Categorize by intensity level

·Low strength level: such as GR.B, suitable for general conveying tasks and occasions with low pressure requirements.

·Medium strength level: such as X42, X52, suitable for conveying tasks with medium pressure requirements.

·High strength level: such as X60, X70, X80, are suitable for high-pressure, long-distance conveying tasks and can withstand higher pressures and environmental challenges.

·Ultra-high strength level: such as X90 and X100, which are the highest strength levels in API5L pipelines, are suitable for conveying tasks in extremely high pressure environments.

2. Categorize by heat treatment method

·Normal heat treatment (N) : After normalizing the pipeline, its strength and toughness can be improved, and its organization and performance can be improved.

·Quenching and tempering Heat treatment (Q) : After quenching and tempering treatment, the pipeline has higher strength and hardness, while maintaining good toughness.

·Acid and corrosion resistant treatment (NS, QS) : For specific transport media (such as acidic media), API 5L Line Pipe can also be acid-resistant and corrosion-resistant treatment to improve their corrosion resistance.

3. Categorize by material

·Carbon steel material:

GR.B: The most common carbon steel material, suitable for general transport media and less demanding occasions.

X series (X42, X52, X60, X70, X80, X90, X100) : With the increase of the number, the strength level of the material is gradually increased. It suitable for high pressure, long distance transportation and other more demanding occasions.

·Special alloy material:

For special conveying media (such as acidic media) or specific working environments (such as high temperature, low temperature, corrosion, etc.), API5L pipes can also be used to add special alloying elements. Such as stainless steel, alloy steel, etc., to meet specific needs.

Application of API 5L Line Pipes

1. Oil and gas transmission: The API 5L line pipe is the core component of the oil and gas transmission system. It can withstand high pressure, high corrosion, high wear and other harsh environments. This ensures the safety and stability of oil and gas delivery.

2. Water supply and drainage engineering: In water supply and drainage engineering, industrial water systems and sewage treatment systems, it can provide reliable fluid transport solutions.

3. Oilfield development: In the process of oil field exploration, development and production, the pipeline can connect the well head, transport oil and gas, water injection gas, etc., to ensure the smooth exploitation and transportation of oil and gas.

4. Power industry: In power plants and transmission systems, API 5L pipes can transport steam, water and other media. It can withstand high temperature, high pressure and corrosive environment. That ensures the safety and reliability of power production and transmission.

5. Building and structural engineering: It can be used as supporting columns, trusses and bridge components of building structures, with high strength and stability.

Contact with us today!