Specification

Cold-rolled low carbon steel, as its name implies, is a low carbon steel material treated by cold rolling process. Cold rolling is a method of steel processing performed at room temperature where hot-rolled steel is further processed by mechanical force to achieve higher dimensional accuracy and surface finish.

As low carbon steel itself contains a low carbon content (usually less than 0.25%), it has good plasticity and toughness, and is easy to process and weld.

| Property | Typical Range | Tolerances |

| Thickness/mm | 0.15-6.0 | ±0.02 – ±0.10 mm (depending on thickness) |

| Width/mm | 500-1850 | ±1.0 – ±3.0 mm |

| Length(or Coil ID)/mm | 1000-6000/508-610(ID) | ±10 mm |

| Tensile Strength/MPa | 220-490 | ±5% |

| Yield Strength/MPa | 160-350 | ±5% |

| Elongation/% | 15-30 | ±2% |

| Hardness/Rockwell | 60-90 | ±5 |

| Surface Finish | Bright, matte, oiled, phosphated, galvanized, etc. | Varies based on finish |

| Flatness | ±0.1 – ±0.5 | Varies based on thickness and width |

Note:

These are typical ranges and tolerances. Actual values may vary depending on the specific grade and manufacturing process.

Need help converting units? Our Metal Sheet Gauge Chart is at your service. Or, simply reach out to our team for personalized support.

Performance Advantages Of Cold-rolled Low Carbon Steel

1. Excellent machining performance

Cold–rolled low carbon steel has excellent processing performance, suitable for deep drawing, bending, drawing and other processing operations. Its high ductility and excellent deep drawing performance make it particularly outstanding in stamping, bending and other forming processes.

Low carbon content makes the material not easy to crack and fracture in the processing process, effectively improve the production efficiency and yield.

2. High surface quality

The application of cold rolling process improves the surface finish and dimensional accuracy of the material, and can meet the needs of a variety of applications without additional surface treatment.

The smooth and uniform surface quality makes this steel can present a more delicate and beautiful appearance after spraying.

3. Excellent mechanical properties

It has high strength, high yield strength and high tensile strength, showing good bearing capacity and deformation resistance.

Large elongation means that when subjected to external forces, large plastic deformation can occur and it is not easy to break, which provides more possibilities for the design of complex structures.

4. High corrosion resistance and high strength

Usually after galvanizing or other surface treatment, its surface forms a protective layer, which provides good corrosion resistance.

It performs well in corrosion-prone applications such as Marine environments, chemical fields and outdoor structures.

5. Environmental performance

As a kind of low carbon and environmental protection steel, cold rolled low carbon steel has shown good environmental protection performance in the process of production and use.

The low carbon content reduces greenhouse gas emissions, while the cold rolling process can use energy more efficiently and reduce waste generation compared to the hot rolling process.

Production Process And Applications Of Cold-rolled Low Carbon Steel

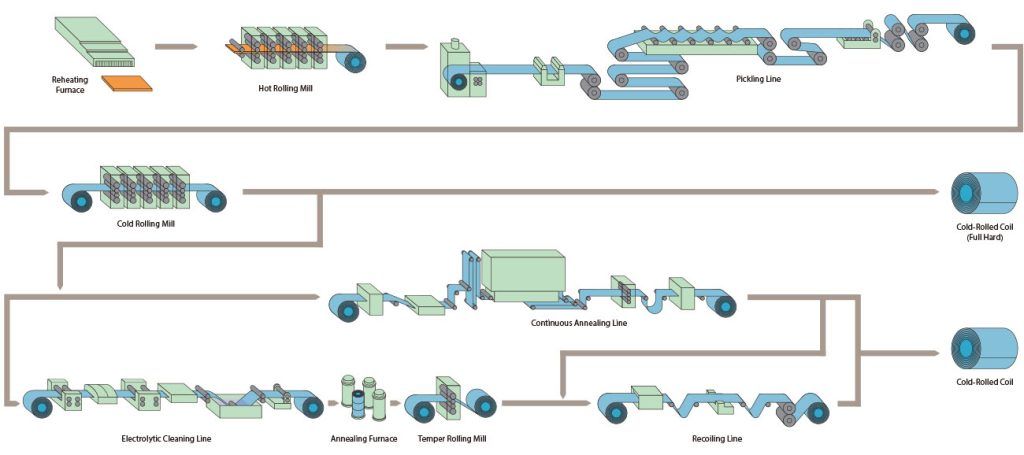

1. COLD ROLLED COIL LINE

2. APPLICATIONS

- Automobile manufacturing

Cold-rolled low carbon steel has a wide range of applications in the field of automobile manufacturing, capable of manufacturing various parts of automobile body, such as door panels, trunk covers, hood and other key components.

These components not only need to have sufficient strength and stiffness to withstand various loads and shocks in vehicle operation, but also need to have good appearance and anti-corrosion performance.

- Home appliance manufacturing

In appliance manufacturing, this steel is used to make the casing and internal parts of products such as refrigerators, washing machines and air conditioners.

Its smooth surface and good corrosion resistance enhance the overall quality of the product.

- Construction

In the field of construction, it can manufacture various profiles, steel plates, networks, rolling doors and elevator wheels.

It has high surface finish, stable and reliable quality, and is widely used in building structures.

- Machinery Manufacturing:

Cold rolled mild steel is also widely used in the manufacturing of automobile, motorcycle, construction machinery and other mechanical equipment parts.

Their high strength and high wear resistance enable these devices to operate stably for a long time.

Contact with us today!