Cold rolled steel and cold drawn steel have significant differences in definition, working principle, process and operation, product application, etc. But they also have certain similarities. When operating these two processes, it is necessary to carry out according to the specific process requirements and equipment conditions to ensure the safety of the operation and the quality of the product.

What is Cold Rolled Steel

Cold rolled steel is the steel produced by cold rolling production process. Cold rolling is a process in which steel plates are further thinned to a target thickness at room temperature. Compared with hot-rolled steel, cold-rolled steel thickness is more accurate. And the surface is smooth and beautiful, but also has a variety of superior mechanical properties, especially in terms of processing properties. Since the cold-rolled steel is processed from the hot-rolled plate at room temperature, although there may be a certain amount of work hardening during the processing because it has not been annealed. It also leads to a certain degree of improvement in its strength.

There are many kinds of cold-rolled steel with different uses, some of which can be directly used for subsequent product processing. And some need to go through some subsequent processing such as annealing, pickling, phosphating and so on. Common cold rolled steel products include cold rolled steel sheet, cold rolled steel strip and cold rolled steel pipe.

Cold-rolled steel has been widely used in many fields, such as construction, automobile, home appliance, machinery and so on, because of its high precision, high surface quality and good processability.

What is Cold Drawn Steel

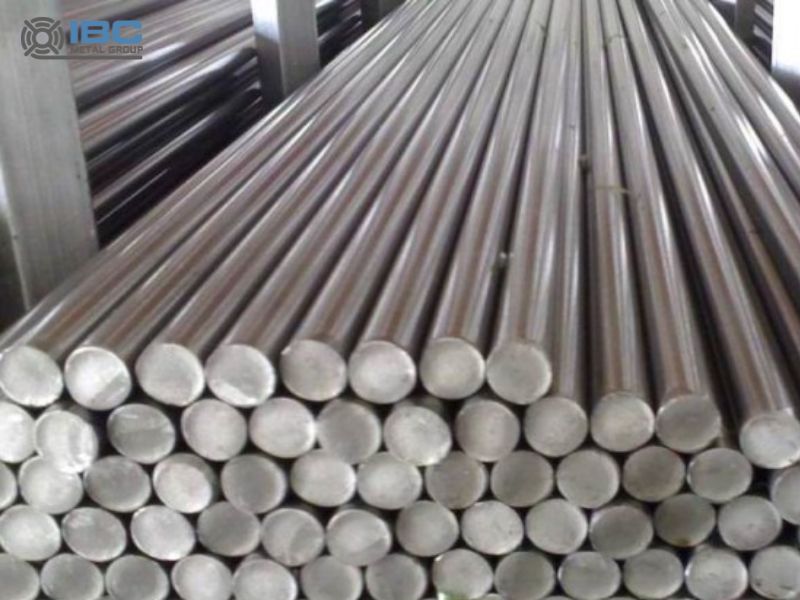

Cold drawn steel is a kind of steel processing technology. It refers to all kinds of steel produced by cold drawing method. Its characteristics include high precision, good surface quality, high strength, high toughness, corrosion resistance and excellent processing properties. The production process usually includes rolling, peeling, passing through the lubricant box and entering the drawing die hole.

This steel has a wide range of applications in many fields. For example, it can be used to manufacture mechanical accessories such as bolts, screws, bearings, gears. And it can also be used to produce electrical components such as wires, cables, and electrodes. In addition, because of its high precision, high quality, high strength and good corrosion resistance. It is also widely used in the automotive industry, oil and gas industry, construction industry, power industry and machinery manufacturing industry.

Cold Rolled Steel vs. Cold Drawn Steel

In terms of process and operation, the former production process includes raw material preparation, pickling, rolling, degreasing, annealing (heat treatment) and finishing, etc. These steps usually require specialized cold rolling equipment to complete. The latter operation mainly includes the rolling head, peeling, passing the lubricant box and entering the wire drawing die hole and other steps. It needs to be carried out on the special cold drawing machine.

The main difference in operation between the two is the difference in the forces applied. Cold-rolled steel mainly adopts compressive stress. So its precision is high, mainly used in some thin-wall steel pipe production with high precision requirements, the main products are plate, strip, foil and so on. The latter uses tensile stress, the accuracy is slightly worse. It mainly used for the production of cold drawn round steel, square steel, hexagonal steel and so on.

In terms of similarity, first of all, they are cold working processes carried out at room temperature to achieve plastic deformation of the metal through dislocation motion. Secondly, in the process of plastic deformation, the motion resistance of the dislocation mainly comes from the dislocation itself. It makes the deformation mechanism of the two have similarities.

Contact with us today!