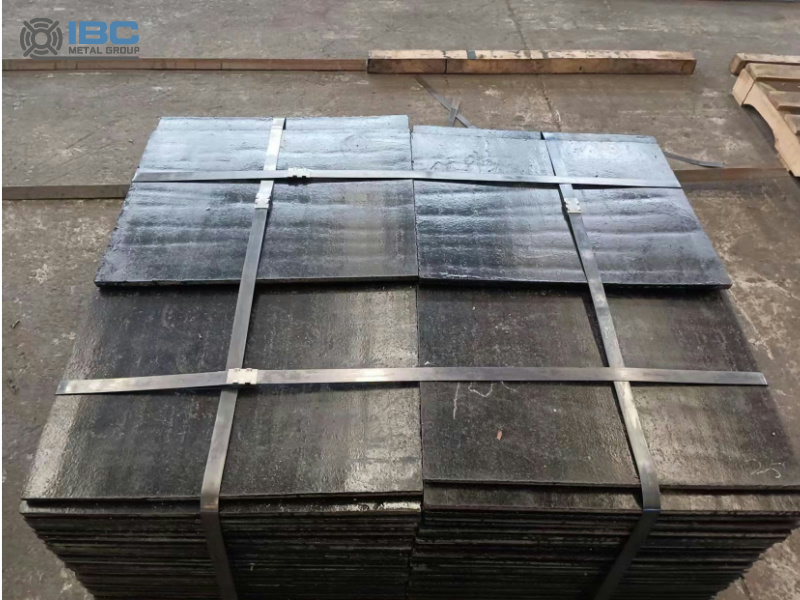

The composite wear plate is mainly composed of two parts: the substrate with good toughness and plasticity (such as ordinary low carbon steel, low alloy steel or stainless steel) and the alloy wear-resistant layer with high hardness and good wear resistance compounded on the surface of the substrate by surfacing welding method.

This structure enables the matrix to provide comprehensive properties such as strength, toughness and plasticity to resist external forces when it is working. The alloy wear layer provides wear and heat resistance to meet the requirements of the specified working conditions.

Operating Steps

First of all, according to the specific needs, the use of appropriate cutting tools (such as plasma cutting machine, laser cutting machine, etc.) to cut it into the desired shape. Secondly, if further processing is required, such as bending or drilling, it should be carried out using appropriate processes and tools. When drilling, due to the high hardness of the wear layer, it is necessary to choose a carbide drill bit and use a lower speed and processing speed to avoid bit damage.

In addition, it can also perform welding operations. Before welding, the substrate needs to be cleaned to remove impurities such as oil and rust on the surface. It can ensure the quality and stability of the welded joint. Then, the worker will choose the appropriate welding equipment and welding method to weld the composite wear-resistant plate. After the welding is completed, it is also necessary to carry out a series of post-processing work, such as cleaning welding slag and non-destructive testing. This ensures the quality and performance of the welded joint.

Performance of Composite Wear Plate

- Excellent wear resistance

Its alloy wear-resistant layer is made of high hardness and good wear resistance alloy material by surfacing welding process. Its wear resistance is significantly better than that of traditional materials such as low carbon steel. And even under the same conditions, the wear resistance can be more than doubled. This is mainly due to the chemical composition in the wear layer of the alloy, such as the high content of carbon and chromium. So the volume fraction and hardness of the carbide have reached a high level.

- Good impact resistance

Its substrate adopts low carbon steel or low alloy steel with good toughness, which can withstand the impact and wear such as high drop hopper, reflecting the superiority of bimetal.

- Excellent heat resistance

The wear layer of the alloy can maintain high hardness and oxidation resistance under normal working conditions (usually ≤600℃). With the addition of specific alloying elements, such as vanadium and molybdenum, it can also withstand higher temperatures, up to 800 ° C.

- Flexible processing performance

It has good processing properties, can be cut, bending, welding and other operations. When cutting, it can be cut into the desired shape using equipment such as a plasma cutter. When connection is required, it can be connected to other structures by welding, plugging or bolting.

- Long service life

Due to the improvement of wear resistance, the service life of composite wear plate is significantly extended, usually more than 10 times higher than that of ordinary steel plate.

IBC Group Give U Best Service

- Excellent product quality

IBC Group strictly controls the procurement of raw materials and production processes. It can ensure the excellent quality and stability of the steel products supplied. Through advanced smelting and rolling technology, we can produce steel products that meet various standards and requirements. And we can provide customers with high-quality raw materials.

- Complete variety specifications

The Group offers steel products of various types, specifications and properties to meet the diverse needs of its customers. Whether it is construction steel, mechanical steel or special alloy steel, it can provide a rich choice, convenient for customers to purchase according to the specific application scenario.

- Strong ability to customize services

We have a strong customization service ability, according to the special needs of customers, tailor-made steel products. From product design, material selection to production process, can be adjusted and optimized according to the specific requirements of customers, to provide customers with personalized solutions.

- Technical support and professional consultation

The group has a professional technical team and consulting team, able to provide customers with comprehensive technical support and consulting services. Whether it is about the performance of steel products, methods of use or technical questions, we can get timely answers and suggestions to help customers better use and utilize steel products.

- Logistics distribution is efficient and convenient

IBC Group has a complete logistics distribution system to ensure timely and accurate delivery of products to customers. Through close cooperation with logistics companies, we can optimize transportation routes and reduce transportation costs. And we can also provide customers with efficient and convenient logistics services.

Contact with us today!