Electrolytic tinplate (also known as tinplate, tinplate) is a traditional can material, the amount is very large. It has good canning processing performance and weldability. And it is widely used in the canning industry, for making cans, cans, boxes of packaged food, cosmetics, candy, biscuits, tea, milk powder, etc. And it is also a good lid material for bottles and cans such as glass and plastic.

Production Process of Electrolytic Tinplate 1

1. Uncoiling the original plate: This step is to uncoiling the original steel plate to provide the appropriate plate for the subsequent operation.

2. Cut the head and tail and weld: After unwinding, cut the unqualified material of the head and tail of the steel plate as needed. And then weld it to ensure that the steel plate is continuous and does not break.

3. Cut the edge: cut the edge of the welded steel plate to ensure that the edge of the steel plate is neat and meet the requirements of subsequent processing.

4. Alkali washing and pickling: alkali washing is mainly to remove oil and oxides on the surface of the steel plate. And pickling is to further remove rust and other impurities on the surface of the steel plate to prepare for electroplating tin operation.

5. Electroplating tin: This is the core step in the production of electroplating tin sheet steel. Workers will put the treated steel plate into the plating tank. Electrolysis makes the tin layer uniformly adhere to the surface of the steel plate. At this time, workers need to strictly control the thickness and quality of the tin layer. This can meet the requirements of the product.

Production Process of Electrolytic Tinplate 2

6. Soft melting: Soft melting is to make the plating tin layer better combined with the steel plate substrate, improve the adhesion and corrosion resistance of the coating. In the process of soft melting, the temperature and time need to be controlled to avoid adverse effects on the steel plate.

7. Passivation: Passivation treatment can enhance the corrosion resistance and stability of the tin coating, and further improve the service life of the steel plate.

8. Electrostatic oiling: The oiling operation is to protect the surface of the steel plate and prevent it from being scratched and corroded during storage and transportation. Electrostatic oiling ensures that the oil layer is uniform and firmly attached.

9. Thickness measurement and clean surface inspection of the coating: Measure the thickness of the coating and check the clean surface of the tinned steel plate to ensure that the coating thickness is uniform, no defects, and the surface of the steel plate is clean and free of dirt.

10. Pinhole detection: pinhole detection is an important part of checking whether there are pinhole defects on the surface of the steel plate. It may affect the performance and appearance of the steel plate.

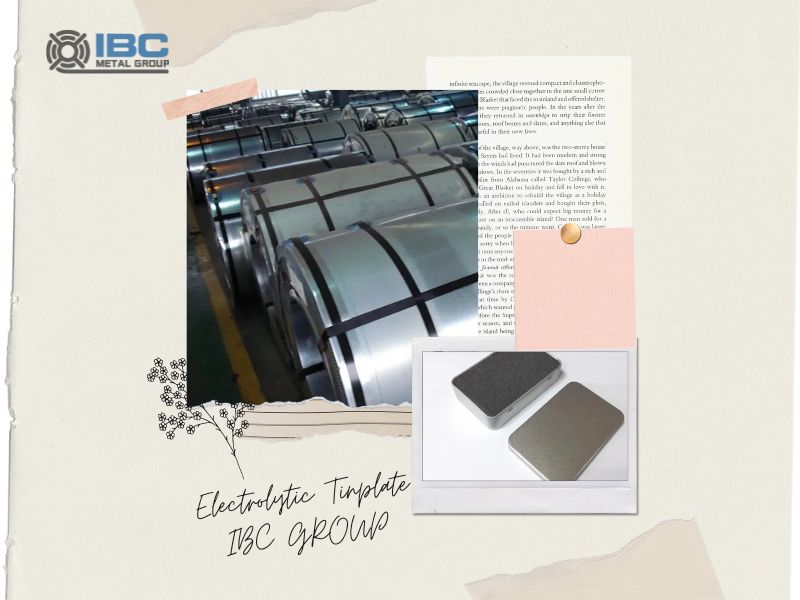

11. Cutting and winding: The steel plate is cut according to the demand. And then the cut steel plate is rolled to facilitate subsequent storage and transportation.

12. Stacking: Finally, the rolled steel plate is stacked, paying attention to stacking neatly to avoid deformation and damage.

Performance Profile

1. Strong corrosion resistance: the surface of Electrolytic Tinplate is covered with a thin and dense tin layer. It can effectively prevent the steel plate from being oxidized and corroded. Thus significantly extending the service life of the steel plate. This characteristic makes it a significant advantage in the manufacture of highly demanding food packaging materials to ensure food safety and hygiene.

2. Good moisture resistance: Because the surface of the steel plate is plated with tin layer, it can effectively reduce the corrosion and damage of water to the steel plate in a high humidity environment. So as to ensure the normal operation of the equipment. This feature makes the electroplated tin plate widely used in the manufacture of home appliances, automobiles and other equipment shells and various mechanical parts.

3. Excellent formability and weldability: It not only has high strength and good formability, but also has excellent welding performance. These characteristics make electroplated tin sheet steel excellent in the manufacture of various containers, stamped products and packaging materials.

4. The appearance is bright and non-toxic: it has high surface gloss, good printing coloring, and the tinning layer is non-toxic, meeting the safety requirements of food packaging.

5. Strong environmental adaptability: It has a strong adaptability to the ambient temperature. And it can maintain stable performance under various environmental conditions.

Contact with us today!