FBE Coated Pipe | Product Description

FBE coated pipe is a kind of pipe product that is coated with molten epoxy powder on the surface of the steel pipe and cured to form anti-corrosion coating. It has excellent anti-corrosion performance and long service life. So this coated steel pipe has been widely used in oil, natural gas, chemical industry, water supply and other fields.

·Product Description

| Standard | DIN30670,CAN/CSA-Z245.21 |

| Size | OD: 219-2000MM |

| Pakcing | in bundles, in loose, Nylon Strip for each bundle for piece pipe |

| Color | RAL colors coating powder |

| Service | anti-chemical corrosion and water resistance strong |

·Epoxy Primer Coated Pipes Coating Specification

| Coating type | Coating Standard |

| 3LPE/3LPP | DIN30670-1991,CAN/CSA Z245,21-2010,ISO21809-1-2009 SY/T 0413-2002,GB/T23257-2009 |

| 2LPE/2LPP | SY/T 0315-2002,GB/T23257-2009,ISO21809-1-2009 |

| FBE(Fusion-bond epoxy) | SY/T 0315-2005,AWWA C213-2001,CAN/CSAZ245.20-2010,ISO218909-2-2007,API RP5L9-2001 |

| Bitumen coatingEnamel &Tape hot-applied | BS534-1990,AWWA203-2002,AWWA214-2000 |

| Liquid epoxy coating | AWWWA C210-2007 |

| Polyurethane insulated coating | SY/T0415-1996,CJ/T114-2000.EN253-1994 |

| Internal Coating | |

| Liquid Epoxy Coating | AWWAC210-2007 |

| FBE | AWWAC213-2001 |

| Cement Mortar Lining | BS534-1990,AWWA C205-2001 |

| Bitumen Coating | BS534-1990 |

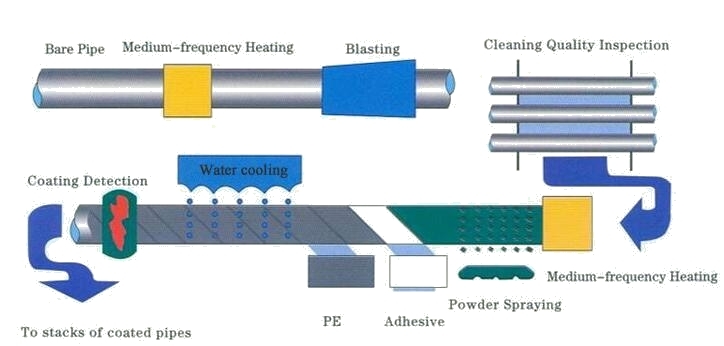

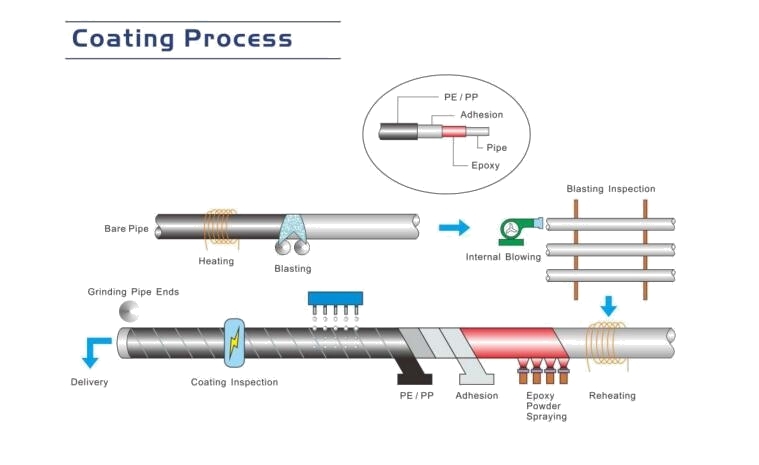

Manufacture Process of FBE Coated Pipe

1. Steel pipe pretreatment

Cleaning: First, workers will thoroughly clean the steel pipe to remove impurities such as grease, dust and rust on the surface. This step usually uses methods such as solvent cleaning, alkali cleaning, or acid cleaning.

Drying: The cleaned steel pipe must be dried to prevent moisture residue from affecting the adhesion and performance of the subsequent coating.

Preheating: In order to make the FBE powder better adhere to the surface of the steel pipe, the factory also needs to preheat the steel pipe. We will control the preheating temperature within the deformation range of the steel pipe material.

2.FBE powder spraying

Powder selection: according to the use environment and performance requirements of steel pipe, select the appropriate FBE powder. FBE powder has excellent corrosion resistance, abrasion resistance and weather resistance.

Electrostatic spraying: the FBE powder is uniformly sprayed on the surface of the steel pipe through electrostatic spraying equipment. Electrostatic spraying uses the principle of electrostatic adsorption to make the powder particles closely attached to the surface of the steel pipe.

Curing: The worker will send the sprayed steel pipe to the high temperature curing furnace for curing treatment. The curing temperature and time are determined according to the type of FBE powder and the material of the steel pipe. The cured FBE coating forms a strong chemical bond layer with the surface of the steel pipe. It greatly improves the adhesion and corrosion resistance of the coating.

3. Coating inspection

Appearance inspection: Check whether the coating surface is smooth and smooth. And whether there are defects such as leakage, bubbles and cracks.

Thickness measurement: Use a professional thickness gauge to measure the thickness of the coating. It can ensure that the thickness of the coating meets the design requirements.

Performance test: Conduct adhesion test, corrosion resistance test and other performance tests to verify whether the performance of the coating meets the requirements.

Performance And Advantages Of FBE Coated Tubes

1. Performance characteristics

Excellent anti-corrosion performance: FBE coating has excellent anti-corrosion performance. It can effectively insulate the corrosion of water, oxygen and other corrosive media on the steel pipe and extend the service life of the pipe.

Strong adhesion: the coating can form a good chemical bond with the surface of the steel pipe. The coating has strong adhesion and is not easy to fall off.

Wear and impact resistance: FBE coated pipe has good wear and impact resistance. And it can resist the mechanical damage that may be encountered during the transportation, installation and use of the pipe.

Wide temperature range: it can maintain stable anti-corrosion performance in a wide temperature range and adapt to various complex environmental conditions.

2. Advantages

Improve the service life of the pipeline: Its anti-corrosion performance can effectively extend the service life of the pipeline, reduce the pipeline leakage caused by corrosion and replacement costs.

Reduced maintenance cost: Due to the good anti-corrosion performance of the FBE coating, the pipeline is less prone to corrosion during use, thus reducing the maintenance cost of the pipeline.

Environmental protection and energy saving: this kind of pipeline has less impact on the environment in the process of production and use. And it meets the requirements of environmental protection. At the same time, due to the excellent anti-corrosion performance, the energy waste caused by corrosion is reduced.

Strong adaptability: it can adapt to various complex environmental conditions, such as high temperature, low temperature, moisture, corrosion, etc. And is widely used in pipeline systems in different industries.

Contact with us today!