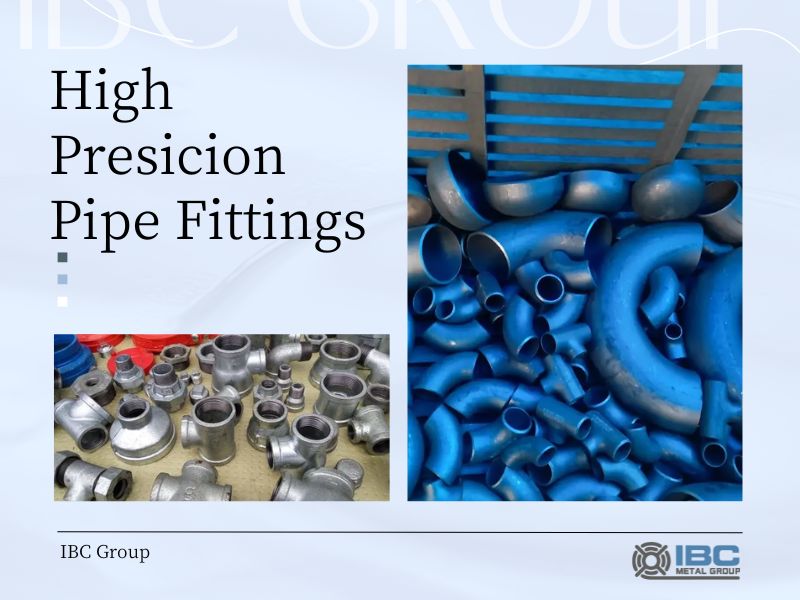

High precision pipe fittings can meet a variety of high-precision requirements of the occasion. Its main features include high precision, high reliability, high sealing and easy installation. These fittings are usually made of high-quality materials with high strength, corrosion resistance and wear resistance, thus guaranteeing the reliability and long service life of the pipe connection.

At the same time, they use advanced sealing technology and sealing materials to ensure high tightness of pipeline connections and effectively prevent leaks. In addition, their structure is relatively simple and easy to install. It can greatly reduce the time and cost of pipeline connection.

Main Function

1. Transmission medium: It can transport various gases, liquids, chemicals and other media, such as oil, natural gas, water, steam, oxygen, nitrogen and so on. Due to its high-precision characteristics, it can ensure the accuracy and stability of the transmission process. And it can reduce the loss and leakage of the medium during the transmission process.

2. Structural support: It can be used as a structural part to support and connect various equipment, buildings, etc. This improves the stability and safety of the overall structure.

3. Heat exchange: In the heat exchanger, it can effectively transfer heat and realize the effective use of heat energy.

4. Electromagnetic shielding: High precision pipe fittings can also protect sensitive equipment from electromagnetic interference, thus ensuring the normal operation and stability of the equipment.

5. Manufacturing precision mechanical parts and engineering structures: Because of its excellent bending and torsional strength and light weight, they are especially suitable for manufacturing precision mechanical parts and engineering structures.

6. Special industry applications: In the medical industry, it can manufacture high-precision medical devices and equipment, such as syringes, catheters, implantable devices, etc. In the field of petrochemical industry, it can transport chemicals and gases such as oil refining, fertilizer and ethylene.

How to Make High Precision Pipe Fittings 1

1. Material selection and pretreatment:

Choose high-quality raw materials, such as seamless steel pipes or specific grades of steel. It should have good mechanical properties and heat resistance.

Pre-treatment of raw materials, including straightening, rust removal, cleaning, etc., to ensure the cleanliness and smoothness of the material surface.

2. Cutting and sizing:

According to the design requirements, the raw material is cut with precise cutting equipment to obtain the required length of the tube blank.

Dimensional trimming of the tube billet to ensure that all parts of the tube fit the design requirements.

3. Heating and forming:

Workers will control the heating temperature of the tube billet according to the material type and process requirements, generally between 900℃ and 1100℃.

Using cold forming or hot forming methods, workers will use special equipment and molds to shape the heated tube billet to form the desired shape of the pipe fitting.

How to Make High Precision Pipe Fittings 2

4. Cold drawing and drawing:

If further precision and surface quality are needed, the plant can also use cold drawing or drawing processes.

In the process of cold drawing or drawing, workers will gradually reduce the diameter of the product through multiple operations to improve the outside diameter accuracy and surface finish.

5. Welding and machining:

If the product needs to be welded, manual or automatic welding methods are used to ensure the quality and tightness of the weld.

Using milling, turning, drilling, threading and other mechanical processing technology, the product is fine processed to meet the design requirements.

6. Annealing treatment:

At certain process stages, such as after cold drawing or drawing, the product is annealed to remove stress and improve toughness and plasticity.

7. Surface treatment:

The surface treatment of pipe fittings is carried out by pickling, phosphating, galvanizing, spraying and other processes to improve its corrosion resistance and aesthetics.

Contact with us today!