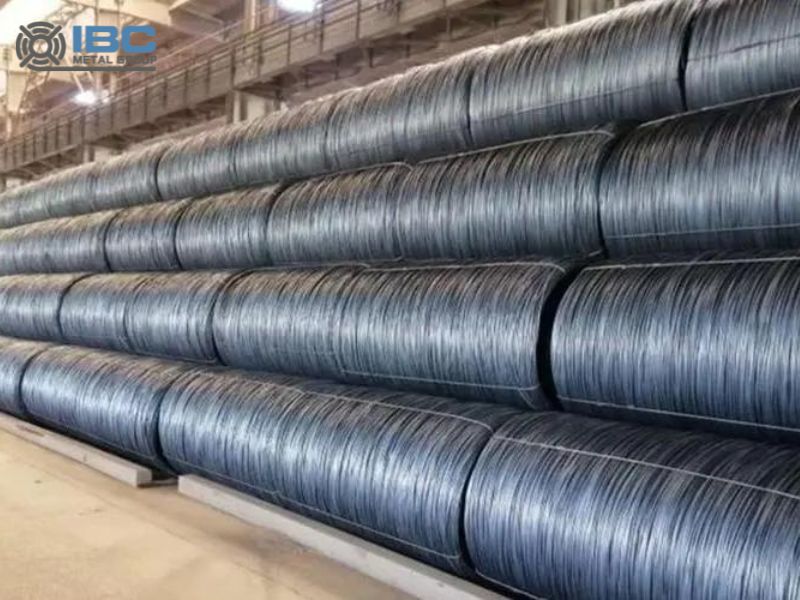

The surface of hot rolled wire rod is slightly rough, but its plasticity is good, and it is easy to carry out follow-up processing. Therefore, it is widely used in construction, Bridges, machinery manufacturing and other fields, as a light round steel bar. The wire can also be reprocessed for use.

In addition, according to the different carbon content, this wire can be divided into hard wire and flexible wire. Wire with a carbon content of more than 0.6% is commonly known as hard wire, and is generally used as raw materials for products such as steel cord, steel fiber and steel strand. Wire with carbon content below 0.6% is commonly known as flexible wire, mainly used in construction and drawing steel wire and its products.

The Difference between Hot and Cold Rolling

1. Hot rolling is rolling above the metal recrystallization temperature, that is, when the metal is heated to a certain temperature, its plasticity will be enhanced, and the deformation resistance will be reduced, so that it can be easier to roll. Because the hot rolling is carried out at high temperature, the oxide skin of the metal will be removed, and the surface quality is relatively good, but the internal structure is the casting structure, and there are certain defects such as coarse grain and uneven performance. Hot rolling is often used to produce large profiles, plates, strips, etc.

2. Cold rolling is rolling under the metal recrystallization temperature, usually using hot rolled coil as raw material, cold rolling after pickling to remove the oxide. Because the cold rolling is carried out at room temperature, the surface quality and dimensional accuracy of the rolled steel are relatively high. But the internal structure is still the casting structure. And the internal stress needs to be eliminated by subsequent annealing treatment to improve the microstructure. Cold rolling is often used to produce thin sheets, high precision strip and so on.

Properties of Hot Rolled Wire Rod

This wire is made by heating the billet to a certain temperature and then rolling it. This metalworking process gives it some unique properties.

First of all, from the appearance, its surface is slightly rough, which is in sharp contrast to the smooth surface of cold-rolled wire. However, it is this slightly rough surface that gives it better plasticity, making it easier for subsequent processing.

Secondly, from the point of view of processing performance, its processing hardness is relatively small, which means that it has good plasticity. This good plasticity makes it easier to achieve the desired shape and size in subsequent processing, so as to meet the needs of a variety of different applications.

Why choose IBC Metal Group

If you want to buy hot rolled wire rod with higher quality and faster delivery, contact IBC Group! We have a very perfect pre-sales and after-sales service:

BEFORE-SALE SERVICE

1. ISO Verified Outstanding Manufacturer

2. The third party inspection: SGS, BV, CE, COC, AI and other .

3. Sufficient Stock

4. Quick Delivery Time, Long time price validity.

5. Tracking picture of transport : production, Loading and reinforcement loading Pictures

6. Rich experience Professioal Sale Team

AFTER-SALE SERVICE

1. Quality Guarantee after Receiving the Goods: Offer money return or Ship new products for free if any problems happen

2. Technical Guidance for further Processing

3. VIP Service and Free Order after Accumulated Order Quantity

Contact with us today!