Silicon steel has excellent magnetism with high permeability and low iron loss value. It also has the advantages of low core loss, high magnetic induction strength, good punching property, good surface quality of steel plate and good insulating film performance.

Therefore, it can manufacture the iron cores of various electric power equipment such as motors, generators and transformers. It is also an indispensable metallic functional material in the power, electronics and military industries. In addition, it can improve the efficiency of power equipment and reduce energy consumption.

Productive Process

1. Raw material pretreatment: First, workers will purchase, mix and pretreat raw materials such as iron, silicon and aluminum according to the formula. This includes steps such as cleaning, crushing and mixing to ensure the quality and purity of the raw material.

2. Melting: Use blast furnace or electric furnace to melt the pre-treated raw materials to form molten steel. In this process, the melting temperature and time should be strictly controlled to obtain a uniform composition of molten steel.

3. Purification of molten steel: The factory will purify molten steel through continuous casting, heat treatment and other ways. This can remove impurities and gases and ensure the purity of the molten steel.

4. Slab rolling: Workers will cast the purified steel into slabs, and then roll the slabs to the required thickness through the rolling mill. In this process, they have to control the rolling speed and temperature to ensure the thickness and performance of the silicon steel plate.

5. Pickling: Through pickling and other methods, oxides and impurities on the surface of the slab after rolling can be removed. This can also improve the surface quality of the silicon steel plate.

6. Annealing and magnetic adjustment: the silicon steel is annealed to eliminate internal stress and improve magnetic properties. At the same time, the material properties of the sheet are further improved through surface treatment and magnetic adjustment.

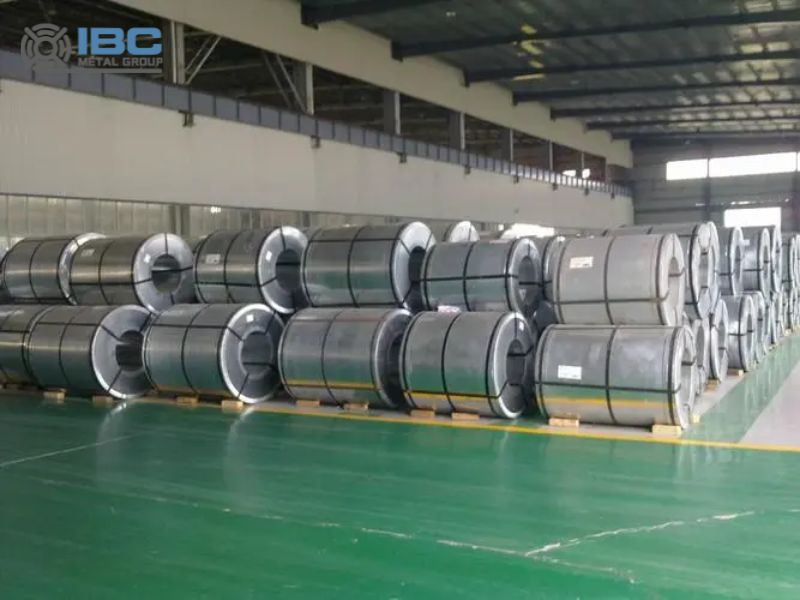

7. Cutting and forming: workers will cut and shape the annealed silicon steel plate to form silicon steel sheets or rolls of different sizes and shapes.

Advantages of Silicon Steel

1. Excellent magnetic properties: silicon steel is known for its low iron loss and high magnetic induction strength. Low iron loss means that less energy is lost during power transmission, thereby improving energy efficiency. The high magnetic induction helps to reduce the excitation current and further save energy. This property makes it an ideal material for the manufacture of highly efficient motors and transformers.

2. Good corrosion resistance: This material also has good stability in wet and acidic environments and is not susceptible to corrosion. This feature makes it widely used in harsh environments such as Marine ships, the chemical industry and oil extraction.

3. Machinability: It is easy to process, cut and form, and can be made into parts and equipment of various shapes and sizes. At the same time, it also has good weldability and plasticity, which makes this steel can be processed and surface treated according to needs in the actual production process.

4. Reduce noise and vibration: its low hysteresis loss characteristics make it almost no magnetic flux loss and eddy current loss during operation, which helps to reduce the noise and vibration of the equipment and improve the stability and service life of the equipment.

5. Material saving: Due to its high magnetic induction intensity, the maximum magnetic induction of the design is high, the core is small in size and light in weight, which can save wires, insulation materials and structural materials, etc., and reduce manufacturing costs.

Contact with us today!