The operation of stainless steel wire rod covers the entire process from raw material processing to finished product manufacturing, requiring professional equipment and technology to ensure product quality and performance.

These operations have a wide range of applications in the stainless steel industry and other related fields. And they are of great significance for promoting industrial upgrading and meeting market demand.

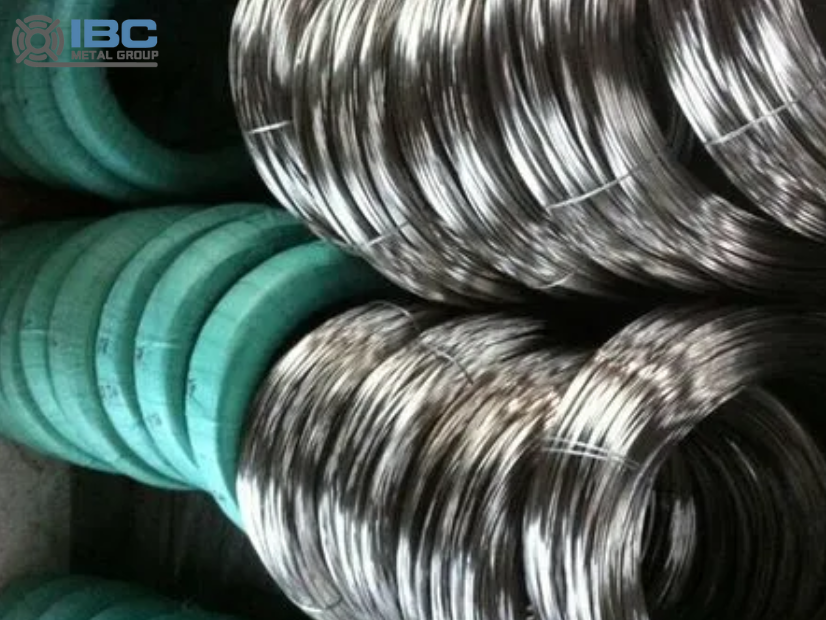

Operation Of Stainless Steel Wire Rod

Unfold and pull

During the production process, wire rods are usually stored and transported in the form of coils. Before use, it needs to be unrolled and drawn to obtain the desired diameter and performance. Drawing is the process by which a material is pushed through a series of gradually decreasing dies by mechanical force, thereby changing its cross-section size and shape.

Cutting and winding

According to the needs of the use, the rod can be cut into a specific length for the production of specific specifications of products. At the same time, it can also be wound and rerolled into a disk roll for easy storage and transportation.

Heat treatment

The wire rod needs to be heat treated during production to change its internal organizational structure, thereby improving its mechanical properties, corrosion resistance or other characteristics.

Quality inspection

It is necessary to test the quality of this kind of wire rod. This includes checking its chemical composition, mechanical properties, surface quality and other aspects to ensure that it meets production requirements and standards.

Performance Profile/ Advantages

First of all, it has excellent strength, toughness and hardness. This enables it to perform well when subjected to various external forces and loads. And it is not easy to deform or break. This characteristic makes it a significant advantage in applications such as stainless steel wire, stainless spring wire, stainless top forging wire and stainless steel wire rope.

Secondly, stainless steel wire rod also has excellent corrosion and heat resistance. It is hot-rolled by a variety of grades of stainless steel with different body types. And its surface can resist the erosion of various corrosive media. And it can maintain its stable performance even in high temperature environments. This characteristic makes it widely used in chemical, pharmaceutical, food and other industries, especially in the manufacture of electrical components that need to work in corrosive environments.

In addition, its price is cheaper than that of copper wire rod. This makes it an ideal substitute for copper wire rod. At the same time, according to different industrial uses. It can also be divided into stainless steel and stainless acid-resistant steel wire rod to meet the needs of different environments.

In terms of process treatment, it also has good processing performance. For example, in the manufacturing process of welding wire rod, by adjusting its chemical composition. So its carbon content is low, phosphorus, sulfur and other toxic impurities are less, nickel, chromium content is high, so as to ensure its excellent welding performance, improve the quality of the weld.

Contact with us today!