Steel wool is widely used. It can be used to clean kitchen surfaces, such as stoves, stoves, ovens, etc., to remove stubborn oil and food debris. Simply wet the steel wool and gently wipe the surface.

In addition, it can also be used to remove rust on the metal surface and restore the brightness and luster of the metal. For the renovation treatment of old furniture, metal utensils, etc. It can also play a role in removing the old paint layer or oxidation layer by wiping, to facilitate the re-painting or repair treatment.

Performance Introduction

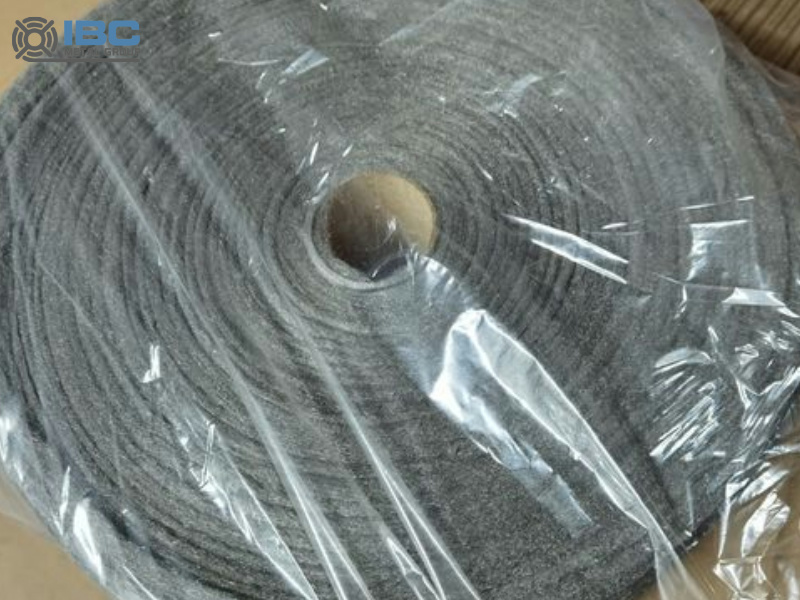

First of all, the steel wool material is unique, composed of low carbon steel filaments, its diameter range between 0.125 and 0.189 mm. This fine wire structure makes it have excellent soft properties. And its wear resistance is also significantly better than that of cotton and linen fiber materials.

Secondly, it has excellent grinding and polishing properties. It can easily grind and polish the surface of stone products, metal products and wood products. And its effect can even be comparable to sandpaper and emery cloth. In stone processing, it is especially suitable for those parts that are not suitable for mechanical grinding and polishing, such as the edge, edge, arc surface of the plate, as well as the convex and concave surface and stone carving, its performance is better than sandpaper and grinding block. And it can easily deal with the surface grinding and polishing of the stone depression.

In addition, this product has a wide range of applications, not only can be used for manual operation, but also can be made into products such as polishing discs, polishing blocks to meet the needs of mechanized construction. This diversified application mode makes it have significant advantages in improving the efficiency, improving the polishing quality and broadening the application field.

Operation Cautions of Steel Wool

1. Security protection

Because of the sharp spines on the surface of the steel wool, be sure to wear gloves during operation to prevent hand injury or scratches. At the same time, ensure the safety of the operating environment, avoid violent fire sources or high temperature stoves, and prevent product deformation due to high temperature.

2. Storage environment

It should be stored in a dry, ventilated, shaded and moisture-proof place, long exposure to sunlight or rain will reduce its service life.

3. Cleaning and maintenance

When cleaning daily, use a clean and soft cotton cloth to wipe, avoid using any acid and alkaline detergent. If you need to use detergent, you should first test in an inconspicuous location. Do not use hard objects or sharp objects to scratch the surface of the product, and do not use acidic or alkaline liquids, iodine, alcohol and other cleaning agents to clean directly, so as to avoid surface corrosion, discoloration and damage.

4. Installation and operation

Maintain its integrity during installation to avoid breakage or shrinkage. Pay attention to the tightness of the installation, timely lubrication, to prevent the bedding from moisture deformation. At the same time, check the temperature of steel wool regularly to prevent bending and deformation.

5. Use and coil

When winding it, such as using tools such as cleaning pads, it should be ensured that the operation is uniform and tight, and the end end should be pressed between the cleaning pad and the product, and should not be exposed. When tearing it, the force should be moderate to avoid excessive force causing it to break or fly.

Advantages of IBC Metal Group

Quality product

The steel wool produced by IBC Group is of high quality, its fibers are fine, uniform, and have strong wear resistance and toughness. This high-quality product can not only meet the needs of various industrial processing and daily cleaning, but also maintain good performance in long-term use, providing users with a reliable experience.

Advanced technology

The company has advanced production equipment and technology to achieve large-scale and efficient production. This not only helps to ensure the quality and stability of the product, but also can meet the large demand of the market. At the same time, advanced technology also enables IBC Group to continue to innovate and introduce new products that are more in line with market needs.

Professional service

IBC Group attaches great importance to customer service and provides comprehensive pre-sale, sales and after-sales services. Whether it is product consultation, ordering or use of the process of the problem, the company can be timely and professional to give answers and help. This professional service attitude has won the trust and praise of customers.

Reasonable price

IBC Group’s products are not only of high quality, but also reasonably priced. By optimizing the production process and reducing the cost, the company provides customers with cost-effective products. This price advantage makes IBC Group’s steel products have strong competitiveness in the market.

Contact with us today!