What is Bell and Spigot Joint Pipe?

Bell and Spigot Joint Pipe is a form of joint used on pipes that have an enlarged diameter or bell at one end and a spigot at the other that fits into and is laid in the bell. The bell and spigot lap weld joint is one of the most commonly used joints in steel water and wastewater transmission pipelines.

The Bell and Spigot Joint Pipe is available for all pipe diameters. It can accommodate very high working pressures. And its easy assembly and fit-up in the field. The bell and spigot lap weld joint has a proven performance history in steel pipe. This joint is an economical method for restraining longitudinal thrust in buried pipes. Joint allows for angular deflection and excellent performance during seismic events. To learn more about this joint, or see if it’s a beneficial solution for your project, please contact our regional support team.

Application of Bell and Spigot Joint Pipe:

- Water transmission pipeline

- High pressure pipelines

- Sites with uneven soil settlement

- Open trench installation

- Areas of high seismic activity

The minimum overlap of the assembled bell and spigot sections is 1 inch/25 mm, or three times the thickness of the belled pipe, whichever is greater. No field welds should be closer than 1 inch/25 mm to the nearest point of tangency to a bell radius. Joint fabrication tolerances follow ANSI/AWWA C206.

Weld integrity inspection and testing follow standard practices outlined in AWWA C206, Field Welding of Steel Water Pipe. Nondestructive testing (NDT) of welded joints include visual inspection and hydrostatically testing of the pipeline and appurtenances, unless alternative nondestructive methods approved by the purchaser.

The bell and spigot joint allows for angular deflection by pulling the spigot relative to the bell as segments connected. For further deflection, the bell can mitered up to 5 degrees. This allows for angular deflection without the use of a fabricated elbow and is useful in accommodating minor alignment changes or long-radius curves

Welded lap joints common in large-diameter buried steel pipelines for water transmission and follow the guidelines outlined in AWWA M11 and AWWA C206. Their lower construction cost and proven history of use make them a trusted, economical joint that remains popular today.

Photos of Spigot and Bell Joint Pipe

The joint is constructed by expanding one end of pipe to create a “bell” shape. The other end of the adjacent plain end pipe segment referred to as “spigot.” Installation teams insert the spigot into the bell end from a slight horizontal angle as they engage. The pipe are then secured with a single or double full-circumferential fillet weld, the weld being equal in size to the thickness of the thinner piece joined. Lap-welded pipe with an inside diameter of 30” or greater can weld from the inside. Interior welding typically used for the “weld after backfill” method of buried pipe installation. With this process pipe joined and heat shrink sleeves installed prior to back filling of the pipe. Interior welding then completed after backfilling, which greatly increases pipe installation rates and lowers the overall cost of the project.

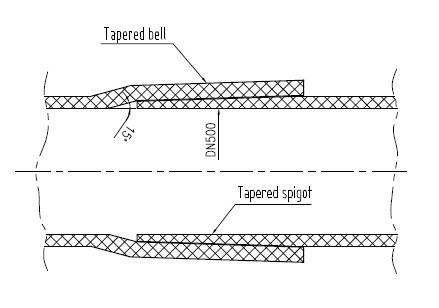

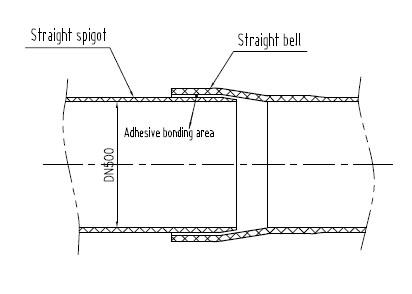

Different Type of Pipe Ends

Tapered Bell and Spigot Joint

Straight Bell and Straight Spigot Joint

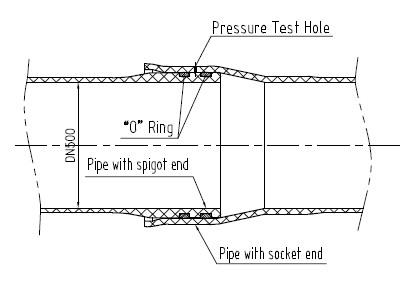

Double “O” Ring Bell and Spigot Joint

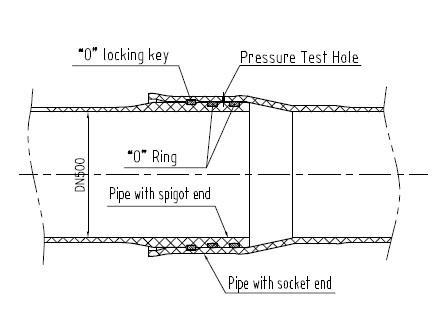

Double “O” Ring Bell and Spigot Joint with Locking Key