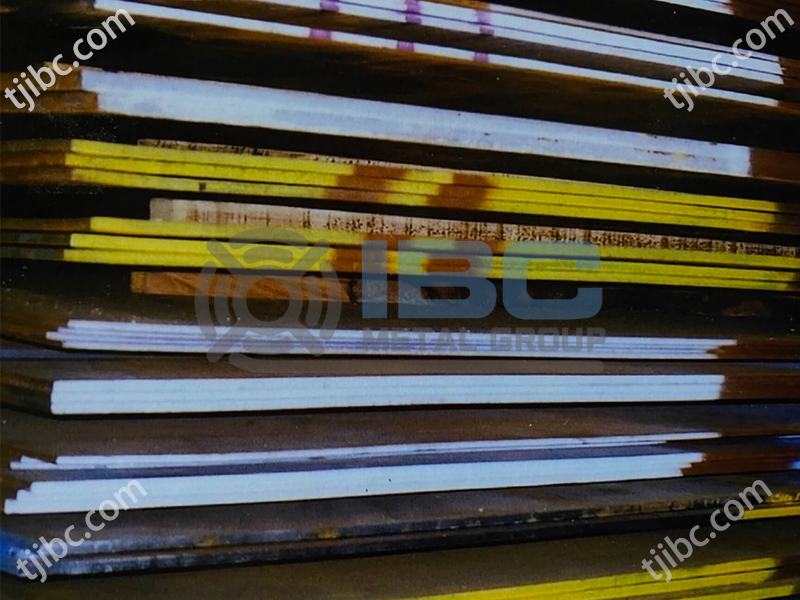

If your application requires superior resistance against impact and wear, then the AR400 steel plate is an excellent solution. As an abrasion resistant 400 steel supplier, IBC (Tianjin) Industrial Co., Ltd provides quality steel in a variety of grades and thicknesses at a competitive price. We carry thousands of tons of Wear-alloy AR400 steel ready to be used in a wide variety of applications, and our team of representatives is here to find you the best steel plate option that best fits your needs.

ASTM A514 AR400 abrasion resistant steel plate is a good candidate for some processing techniques. This material characterized by a smooth, dark scale finish with a hardened surface. While not a good candidate for forming and machining, AR400 plate is suitable for welding. Intended for moderate wear applications, common uses include contact surfaces, hoppers, cement mixer drums and fins, and shooting targets. ASTM A514 is the standard specification for high yield, quenched and tempered alloy steel plate, suitable for welding.

What is Wear-alloy AR400 Steel?

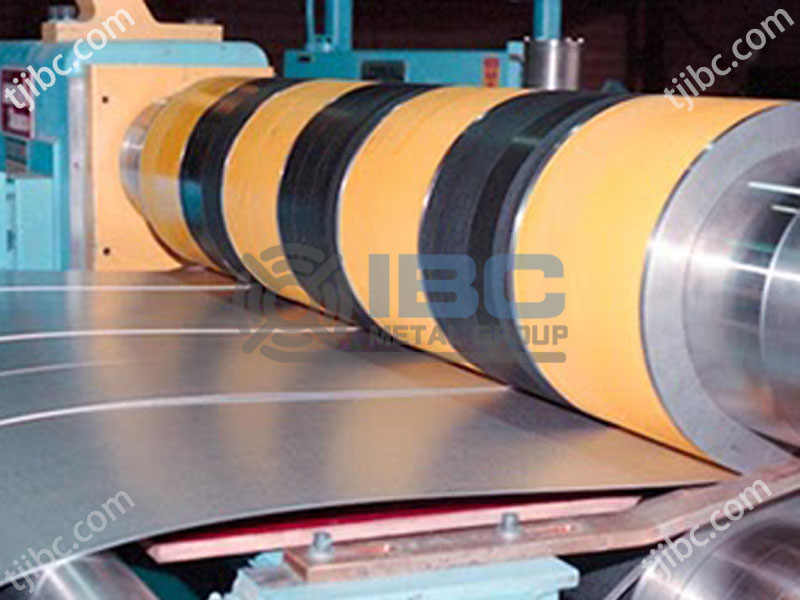

AR400, also known as Wearalloy 400, is a high-carbon steel with a nominal hardness of 400 and a minimum hardness on the Brinell scale of 360 to 440. We created Abrasion resistant steel by quenching and tempering forged steel plates. Quenching occurs by bringing the steel to a high temperate, between 1,500 and 1,650F, then quickly cooled with water. During the tempering process, the steel re-heated again below-critical temperature from 300 to 700F then cooled to room temperatures. The quenching process creates a crystal structure within the steel that increases the hardness, while the tempering increases the steel’s overall durability. The quenching and tempering process change the grain structure to increase the toughness and formability that result in a through-hardened material.

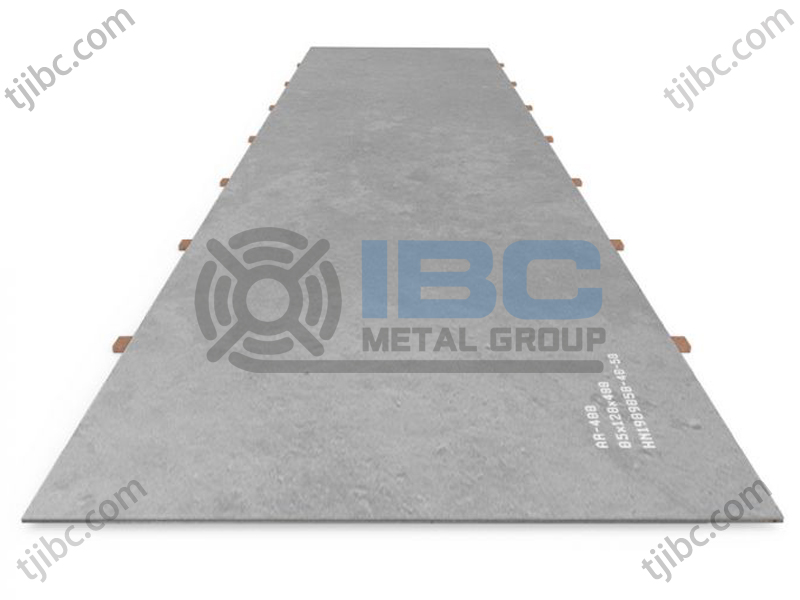

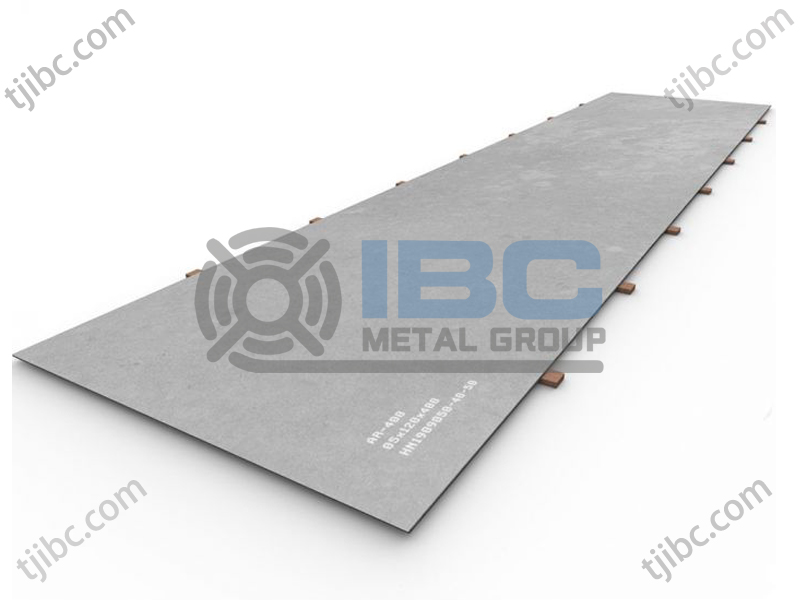

Sizes Offered

At IBC Metal Group Steel, we produce a variety of AR400 steel plates and bars in different sizes. The thicker the size, the more impact resistant the steel has.

- Thickness: 1/8” thru 4”

- Widths: 48” thru 96”

- Lengths: 96” thru 288”

Benefits of Wear-alloy AR400 Steel

The AR400 steel plate is excellent for applications that weldability and formability are a must. The steel plate versatile, and cut it to fit tighter spaces. Abrasion resistant 400 steel proven to have the best-prolonged service life where abrasion is the cause of failure. Additional benefits AR400 steel offers that include: Three times the strength as mild steel; Low cost; Reduces maintenance costs; Wear-resistant for temperatures under 250°C; Through-hardness

Common Industries and Applications

Due to AR400 steel’s unique strength, it used in common industries that deal with impact or sliding abrasion. The abrasion resistant steel found in several industries such as mining, aggregate, construction, pulp & paper, and cement.

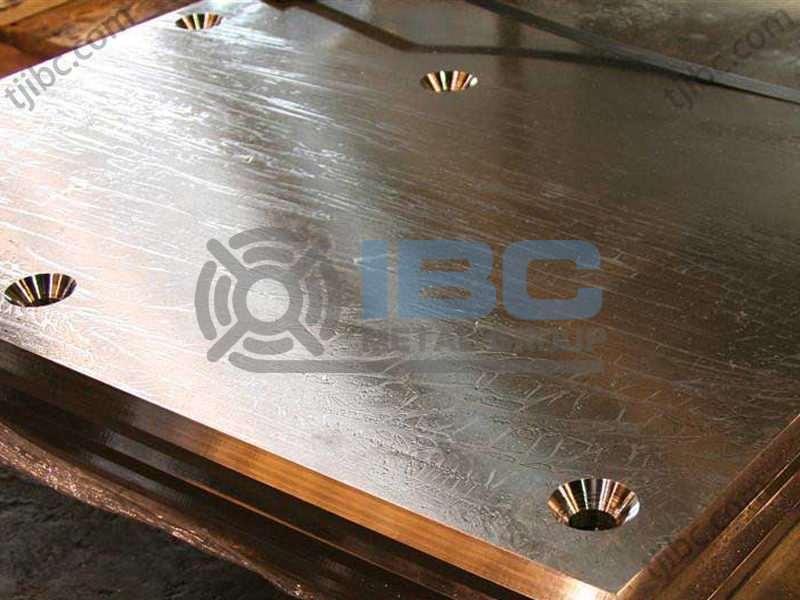

Drilling and Machining

Wearalloy AR400 can be machined or drilled with high speed carbide tools at low speeds. As the hardness level of the plate increases, it is necessary to decrease the cutting speed and feed depth. Available Services: Welding; Shearing and Punching; Forming; Fabrication and steel for mining.

Conclusion

IBC Metal Group supply & export AR400 Steel Plate to all over the world with high quality and competitive price. AR400 specifically designed for abrasion and wear-resistant applications. AR400 has a typical hardness range of 360-444 BHN, which is slightly lower than AR450. As with other abrasion-resistant steels, it does not have defined chemistry, but rather, the grade determined based on hardness.

IBC Metal Group produce an wide range of thicknesses of AR 400 that can be purchased in just the size you need. Give Us a call or fill the contact form for additional thicknesses, sizes and custom shapes.

Contact with IBC Metal Group