As a global leader and Wear-alloy AR450 steel plate supplier, IBC Metal Group produce a variety of abrasion resistant plates in different sizes and thicknesses. Wear-alloy 450, or AR450, lasts four times longer than other carbon-alloy steel plates. Compared to AR400, the AR450 steel plate offers more hardness without sacrificing formability and ductility.

With our highly trained team of representatives, we pride ourselves in providing excellent customer service to provide you with the best solution to your specific wear problems. Our team of experts create solutions to complex challenges and to help you avoid unnecessary downtime at a low-cost solution.

What is Wear-alloy AR450 Steel Plate?

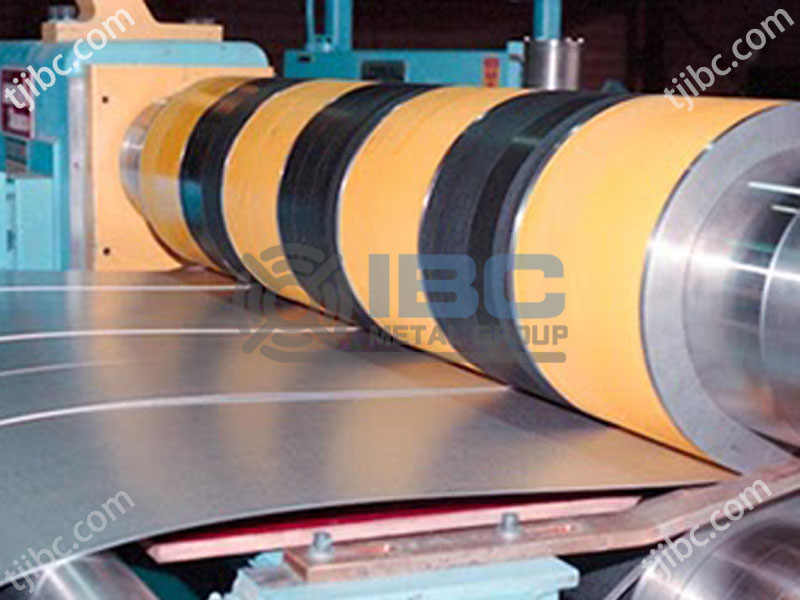

Wear-alloy 450 Steel, also known as AR450F or AR450, is high-carbon alloy steel composed of a variety of elements, such as boron and carbon, with a surface hardness of 420-470 Hardness Brinell. AR450 is a type of abrasion resistant steel that has a unique hardness, formability, ductility, and impact resistance. The steel plate undergoes a quenching and tempering process that subjects the steel plate to heat, submerging in water, reheating, then placed in a room temperature area dry that creates a stronger crystal structure.

Sizes Offered

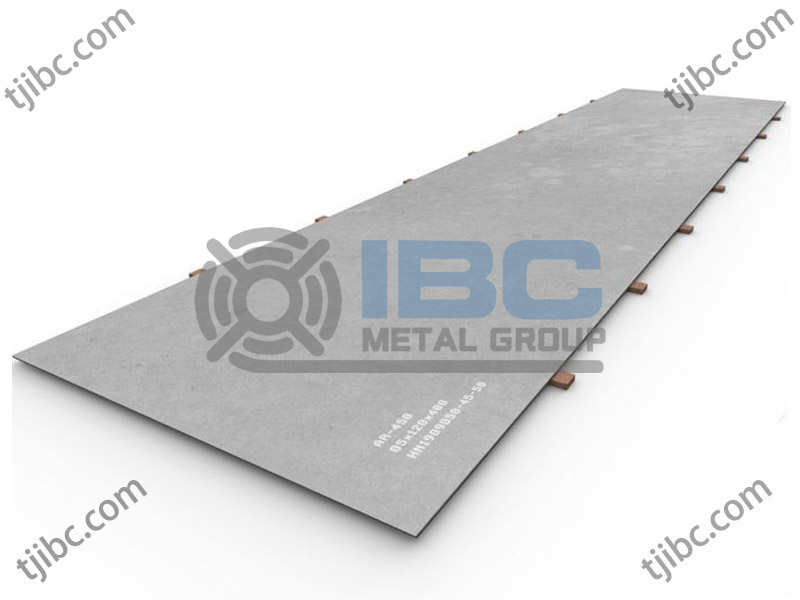

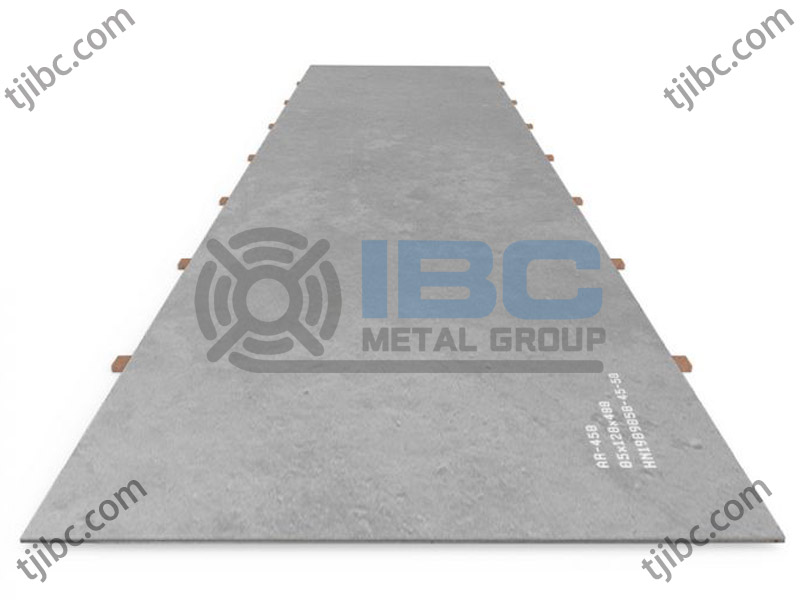

As one of the leading abrasion resistant providers in the industry, Ford Steel houses an assortment of AR450 steel plates in different thicknesses. The common range of thickness for AR450 steel plates range from ⅛ inch to 4 inches and come in a variety of lengths depending on the application requirement.

- Thickness: 1/8” thru 4”

- Widths: 48” thru 96”

- Lengths: 96” thru 288”

What are the Benefits of AR450 Steel Plate?

AR450 steel plate can reduce industrial wear application issues that may arise due to rubbing or scraping and erosion. By reducing wear, it can maximize your production time and minimize any downtime you previously suffered due to worn parts; This may also improve the longevity of your machinery.

Abrasion resistant 450 plate protects your equipment from corrosion, wear, and impact. The steel is superior for applications that require more durability, minimizing the lost production time because of worn-out parts. AR450 has many other benefits including: Less Cost; Less weight without sacrificing strength; Extremely durable; High Impact resistance.

Heat-Treatment

The steels are not intended to be heat treated during or after fabrication. Tempering at moderate temperatures, 150°C – 200°C, is the only heat treatment which will without fail allow the steel to retain its original wearing properties.

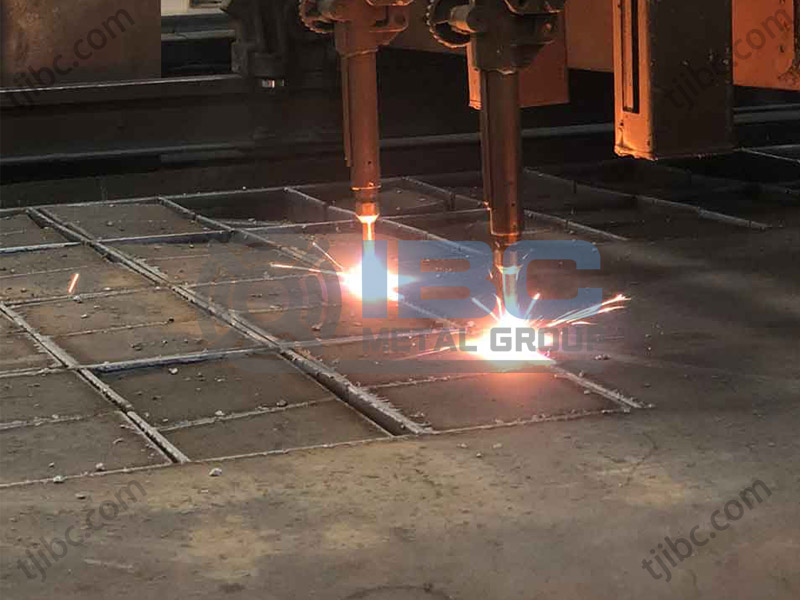

Flame Cutting

A heat affected zone will build up on a thermally cut surface which is similar to the heat affected zone on a fusion welded steel surface. The surface hardens to a depth of 1mm-2mm during flame cutting and post heat results in a soft tempered layer below this. When flame cutting, the pre-heating and working temperature instructions concerning welding can be used as a guideline. In practice it is advisable to preheat when cutting plates, if the thickness is over 10mm.

The maximum allowable working temperature must be kept below 200°C in order that the wear resistance will meet requirements throughout the plate. The cooling of a cut surface must not be accelerated under any circumstances, on the contrary, the cooling of the plate surface can be slowed down if necessary. A plate brought in from cold outside storage must be allowed to warm up sufficiently before cutting.

Working Temperature

Increasing the working temperature slows the cooling of welded joints, which decreases the generation of a microstructure that is too hard and brittle and vulnerable to cracking in the heat affected zone. It is advisable to increase the working temperature of AR 450 steels when the combined plate thickness exceeds about 40mm. Generally a good working temperature of 100°C is enough to ensure a good result. However, when heavy and complicated structures are welded and when welding takes place under difficult circumstances, a higher 150°C – 200°C, working temperature is recommended. A higher working temperature than this may weaken the mechanical properties.

Common Industries and Applications

Our AR450 steel plates meet all requirements and standards for EN 10029 and EN 10051. Available Services: Drilling and machining, welding, shearing and unching, forming, Fabrication.

AR450 steel plates are used in heavy equipment manufacturing jobs that rely on it to protect the equipment from extensive wear. The steel plates should not be used in load-bearing or structural design to support extensive amounts of weight. Common industries that use AR450 steel are mining, power, aggregation, cement, pulp/paper, sand & gravel, asphalt, scrap, and slag.

Conclusion

IBC Metal Group provide factory price with trading company services. Production quality control very strictly to keep none compensation. We accept small order quantity before formal cooperation. Offering good quality with reasonable price, faster delivery with better payment terms. We have professional teams and the factory. It’s very important for a company to be honest in the process of trading and so do we. That’s our advantages. If you need more information, please contact with us.

Contact with us!