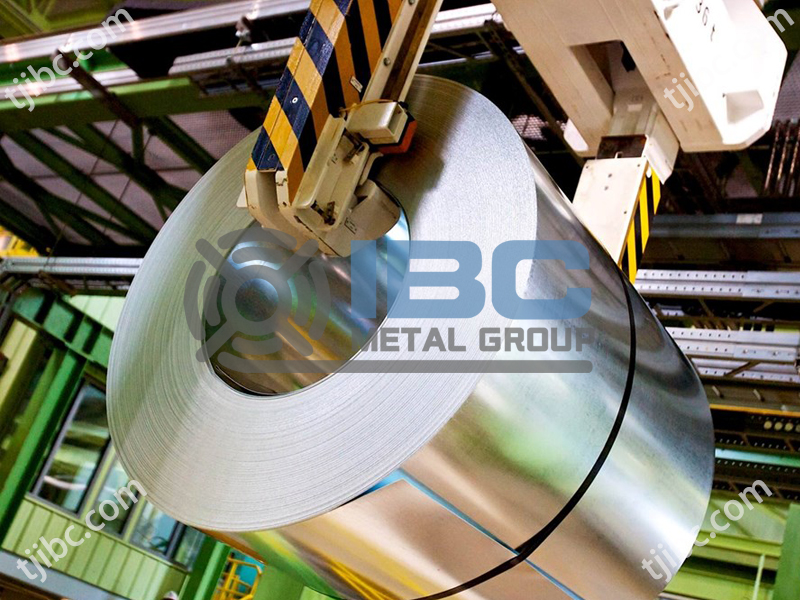

Aluminized Steel Products and Services

IBC Metal Group is the world leader in processed ASTM A463 aluminized steel products. This steel meets high industry and ASTM standards, with superior forming abilities and deep-draw processing performance. It is an ideal material for hot environments, retaining its original appearance up to 900 degrees F and reflecting 80 percent of its surrounding radiant heat. The aluminum and silicon alloy coating provide great heat resistance as well as impressive corrosion protection, outperforming lower melting temperature materials like zinc coated (galvanized) steel.

Different Types of ASTM A463 Aluminized Steel

Type 1: Hot-dip coated with an aluminum/silicon alloy containing between 5% and 11% silicon to improve adherence. In addition to heat resistance, it is also suitable for corrosion resistance and heat resistance. Mufflers, furnaces, ovens, ranges, heaters, water heaters, fireplaces, and baking pans can be used as end uses.

It is intended primarily for applications that require resistance to atmospheric corrosion. Type 2 can ultimately be manufactured into corrugated roofing and siding, grain bins, air conditioner housings, and drying ovens.

Specification of Aluminized Steel ASTM A463

There are two types of aluminum coatings that can apply by hot-dip in this specification, as well as a wide variety of coating weights, for aluminum-coated steel sheet in coils and cut lengths. Heat analysis requirements for base metals must be met, mechanical properties requirements for structural steel and high strength low alloy steel must be met, and coating weight and bend tests must be met.

Application of ASTM A463 Aluminized Steel Products

Aluminized sheet, also known as aluminized steel or hot-dip aluminized sheet, widely used in a variety of applications. IBC Group provides these materials with different grades to efficiently resist heat and corrosion. Such qualities make it an ideal choice for products like water heaters, brooder reflectors, furnace walls & doors, heat exchangers, drying ovens, home & industrial incinerators, space heaters or any small or large appliances.

Widely used:

- Mufflers, exhaust pipes and fuel tanks for automobiles and motorcycles.

- Combustion furnace, heat exchanger, dryer, air conditioner, etc.

- Household water heaters, gas stoves, bread boxes, chimneys, microwave ovens, food processing machinery, electric ovens, cooking utensils. It can also use for building covers, walls, ceilings and other thermal insulation components.

By hot-dipping carbon steel with an aluminum-silicon alloy, aluminum coated steel provides high temperature resistance as well as a bright appearance. Silicon promotes the coating’s adhesion to the base metal. At temperatures up to 900 degrees Fahrenheit, aluminum sheet and coil will maintain their bright appearance and provide long-term service compared to zinc-coated products.

Even though aluminum corrodes faster than zinc, the oxide that forms on aluminum adheres tightly, protecting the base metal. In addition to special specification products, surface post-treatment can further improve the corrosion resistance of the material based on the application (chrome treatment, no (hexavalent) chromization treatment).

Aluminized Steel Grade Classifications:

- CS – Commercial Steel type A, B, and C

- FS – Forming Steel

- DDS – Deep-Drawing Steel

- EDDS – Extra Deep-Drawing Steel

- SS – Structural Steel

- HSLAS – High Strength/Low Alloy Steel

Why Choose IBC Metal Group

- Profession — 10+ years experiences in CRC, GI, and PPGI products.

- Trustworthy — Strategic partner of famous brands, such as Sayo, Hair, Moutai, Nippon Paint, Iris etc.

- Own brand — IBC Metal, which is high-middle level brand in coated steel products

- The 3rd party inspection — at any time, at any place

Advantages

- Expertise: We know how to properly handle every step of production.

- Materials: All color steel sheets made of high-quality raw materials.

- Productivity: We guarantee all your orders will finish in earliest time.

We are the biggest coating steel exporter in North of China, which can mainly provide Aluminum coil Prepainted galvanized / galvalume steel coil (PPGI/L), galvanized / galvalume steel coil (GI/L) and cold rolled steel coil (CRC), Aluminum coil, Zn-Al-Mg coil etc.

Conclusion

Welcome to IBC Metal Group, a company with years of knowledge in coated steel products. Our specialty is CRC, GI/GL, PPGI/PPGL and ASTM A463 Aluminized Steel Coil / Pipes Aluminium-Silicon Alloy Steel Coil. Our products stand out for their performance and style, produced by top-notch materials that meet industry standards. We are proud to commit to our motto of “Supply better material for projects and find best solution for customers” – helping partners worldwide reach their goals. Our advanced imported equipment allows us to deliver quality components that will complete your requirements. We look forward to working with you!

Contact with IBC Metal Group