IBC (Tianjin) Industrial Co., Ltd manufacture & supplying 0.8mm aluminized steel coil to all over the world. Aluminized steel both has strength as steel, and maintaining aluminum’s advantageous surface qualities. It also has good formability, too. So metallurgists can bend, fold, corrugate, and roll it without breaking.

What is Aluminized Steel?

In order to improve its properties, especially corrosion resistance and rust resistance, aluminum or aluminum silicon are added to the coated steel during the hot dipped process. In hot dipping, steel is dipped in aluminum vats to give it superior surface properties that significantly improve its performance and physical characteristics, making it comparable to stainless steel in terms of performance and physical characteristics.

Aluminized Steel’s Properties

Aluminized steel is formed by coating carbon steel with an aluminum-silicon alloy by hot-dipping. By combining the best features of steel and aluminum, the new material combines steel and aluminum by creating a tight metallurgical bond between the base metal (carbon steel) and its alloy coating.

Aluminized steel is highly resistant to corrosion because of the thin layers of aluminium and silicon that keep the steel from oxidizing. Especially when exposed to salts, these thin layers also prevent pit corrosion from taking place. Although aluminized steel has good corrosion resistance, if the aluminium layer is disrupted and exposed, the steel may oxidize and corrosion may occur.

Types of Aluminized Steel

There are two types of aluminized steel depending on the purity of its coating. First one method hot-dip coated with a thin layer of aluminium-silicon alloy. In order to promote better adherence adding 5% to 11% silicon. It is intended principally for heat resisting applications and also for uses where corrosion resistance and heat are required. Possible end uses are mufflers, furnaces, ovens, ranges, heaters, water heaters, fireplaces, and baking pans.

Aluminized steel can withstand 550 °C (1,022 °F) with almost no change in the base material. But due to silicon content it develops black spot. Aluminized steel has slowly started to convert bakery trays which were previously made by galvanized or galvalume steel as it does not contain lead which is poisonous. Type 1 also commonly found in industrial products.

Second method, hot-dip coated with commercially pure aluminum which is often thicker than first one’s coating. It intended principally for applications requiring atmospheric corrosion resistance. Pure aluminum method may ultimately be manufactured into corrugated roofing and siding, grain bins, drying ovens, and air-conditioner condenser housings.

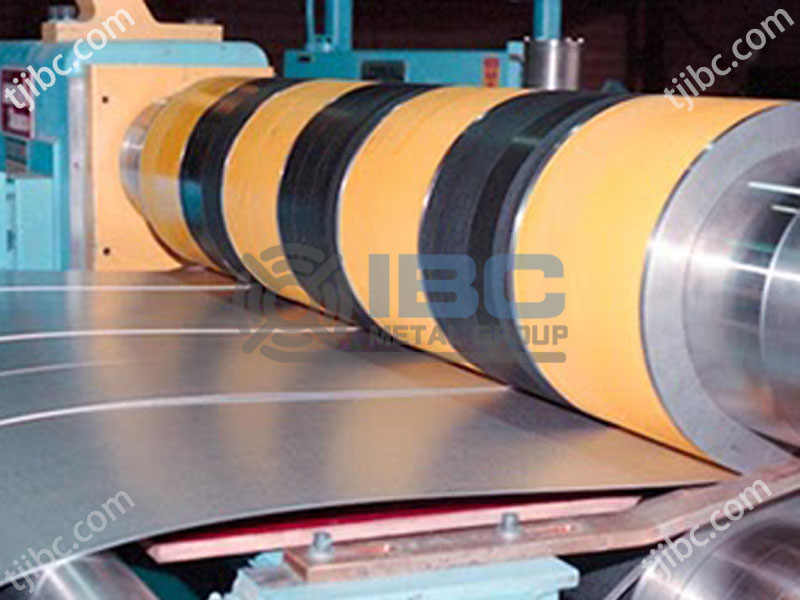

Uses – All Sizes – 0.8mm Aluminized Steel Coil

During hot pressing, Al-Si coatings protect boron steel. It is commonly used in applications involving high temperatures and corrosion resistance. ① Aluminized steel developed for providing more structural durability and a high yield strength in highly corrosive environments. It maintains the strength of high-alloy steel, but is cheaper to produce than high-alloy steels and thus is a preferred material for manufacturing automobile and motorcycle exhaust gas systems. ② Its resistance to high temperatures makes it ideal for incinerators, ovens, heaters, kitchen ranges, and barbeque burners. Additionally, the aluminum-silicon coating doesn’t rust or affect the flavor of food, making it sanitary for cooking ware like baking pans and pots. ③ Its resistance to corrosion, meanwhile, makes it great for HVAC components and pipes in industrial facilities that carry corrosive liquids.

Conclusion – Quality 0.8mm Aluminized Steel Coil

Aluminized steel is the perfect material for a variety of uses. For quality assurance, consider obtaining your supplies from IBC Metal Group, an expert steel service company. We make sure to follow your exact directives when selecting and processing our items. To meet your desired physical and chemical characteristics, including tensile strength, yield and elongation, as well as rock-well hardness, our aluminized steel coils come in various thicknesses, ranging from 0.8mm to any other size you need.

IBC Metal Group covering value service, including steel slitting, steel sheared, cut-to length or blanked. Call us, or fill out our online form for more information about our services. We will be there waiting for you.

Frequently Asked Questions

Is Aluminized Steel Better Than Stainless Steel?

Aluminized steel has a higher thermal resistance than stainless steel, making it a more logical choice when building items that exposed to a higher temperatures such as furnaces, vehicle exhaust systems, and water heaters. However, aluminized steel also prone to corrosion if the aluminum coating is broken away, which could compromise the structural integrity of a building.

Is Stainless Steel Lighter Than Aluminized Steel?

Stainless steel is a mixture of steel with at least 10.5% chromium, in addition to other elements. The complex process used to create stainless steel allows for a strong, corrosion-resistant metallic alloy to be formed. Stainless steel is heavier than aluminized steel in most cases, and the weight and physical properties of the stainless steel can vary based on the grade.

What is the Difference Between Aluminum and Aluminized Steel?

Steel (iron) is dipped into molten aluminum to form a corrosion-resistant coating. Aluminum is an element known for its corrosion resistance. Aluminized steel consists of three layers: an innermost steel core, a middle layer of aluminum, and an outer layer of oxidized aluminum (that has been exposed to oxygen).

Does Aluminized Steel Rust?

The aluminum coating on the exterior of aluminized steel is intended to create a higher resistance to corrosion or rusting. In the event that the coating peels away, chips, or breaks, the steel core can be exposed to corrosion and rust over time, resulting in structural failure. If the outermost aluminum layer is removed, aluminized steel can rust.