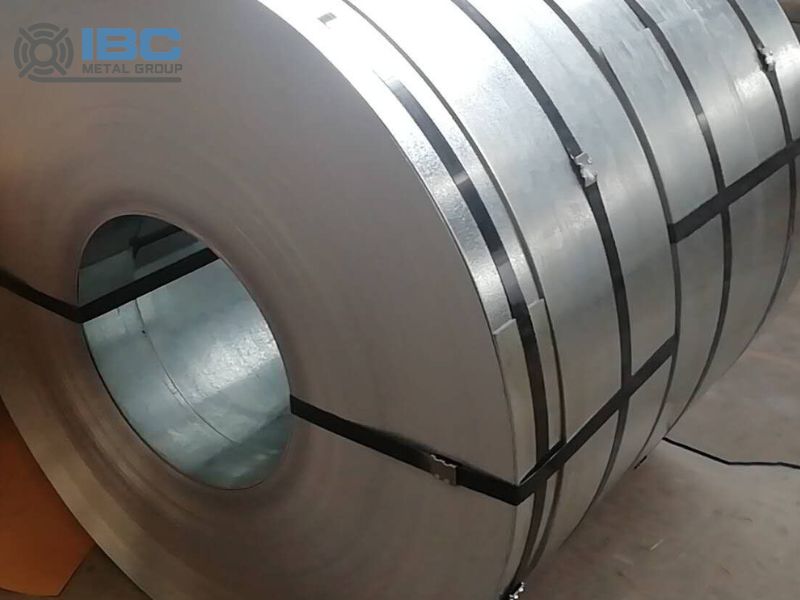

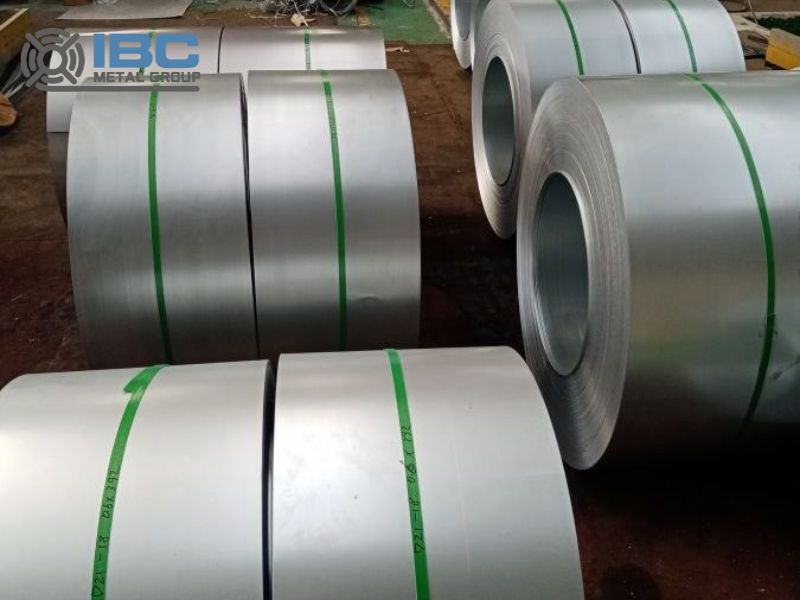

Non oriented silicon steel coil, also known as non-oriented electrical steel, is a special electrical steel material. It is obtained on the basis of ordinary silicon steel by special rolling and annealing processes. The main feature of this material is that its grain structure presents a non-oriented state. That is, the orientation of the grain has no obvious orientation. So that its magnetic properties in different directions are basically the same.

How to Produce

1. Steelmaking: Using high-purity raw materials, smelting by converter or electric furnace, controlling chemical composition and temperature to obtain high-quality molten steel.

2. Continuous casting: The workers will continuously cast the molten steel into a certain specification of slabs to provide raw materials for the subsequent hot rolling process.

3. Hot rolling: Workers heat the slab and then roll it at high temperature to form a hot rolled strip with a certain thickness.

4. Pickling: Remove the oxidation scale on the surface of the hot rolled strip to provide a clean surface for the cold rolling process.

5. Cold rolling: at normal temperature, workers roll hot rolled strip steel several times to make the desired sheet.

6. Annealing: In order to eliminate the internal stress generated during the cold rolling process and improve the magnetic properties and processing properties of the silicon steel sheet, it is necessary to annealing.

7. Finishing: trimming and leveling the annealed silicon steel sheet to obtain a non oriented silicon steel coil that meets the requirements.

Properties of Non Oriented Silicon Steel Coil

It has excellent electromagnetic properties and processing properties. and is widely used in power, electronics, communications, home appliances and other fields. Its main properties are as follows:

1.High magnetic induction: It has a high magnetic induction intensity. It is conducive to improving the efficiency and performance of the motor.

2. Low iron loss: The iron loss generated in the alternating magnetic field is small. It is conducive to improving the operating efficiency of the motor.

3. Good punching property: easy to punch and process, to meet the various processing requirements in the motor manufacturing process.

4. Excellent insulation performance: The surface has a good insulation coating to prevent short circuit and breakdown during the operation of the motor.

Applications in Various Fields

1. Power industry: It is the core material for manufacturing power transformers, which is used to improve the efficiency of transformers and reduce energy consumption.

2. Electronics industry: Manufacture of electronic components such as inductors, relays and ballasts in the field of electronics.

3. Communication industry: Manufacture transformers, filters and other key components of communication equipment to ensure the stable operation of communication equipment.

4. Home appliance industry: Motor manufacturing of appliances such as electric fans, washing machines, air conditioners and other equipment to improve the energy efficiency and performance of equipment.

In short, non oriented silicon steel coil has been widely used in various fields because of its excellent electromagnetic properties and processing properties. It is of great significance to promote industrial development and improve product quality.

Contact with us today!