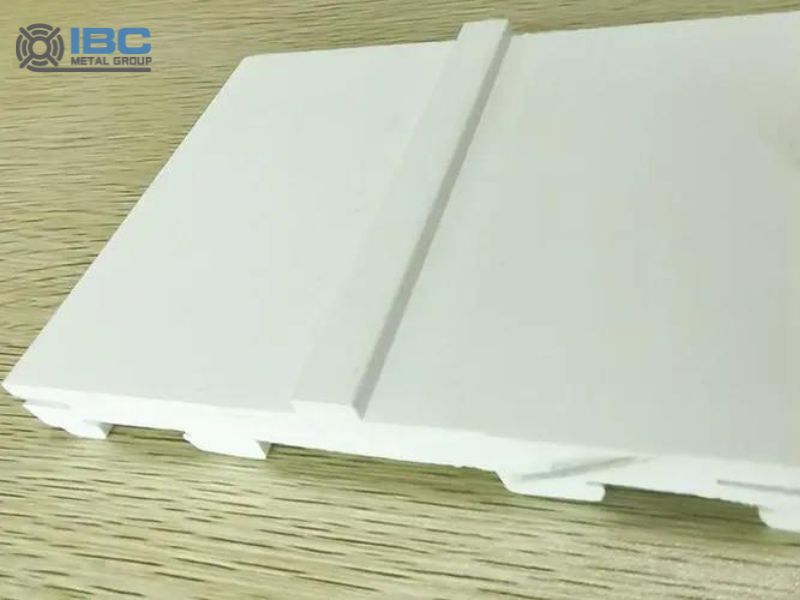

PVC sheet, full name of PolyVinyl Chloride (PolyVinyl Chloride) plate. It is made of PVC as raw material, and the cross-section is made of honeycomb network structure. In addition, this material is also a decorative film, bonding film. It is a vacuum blister film that can pack a variety of panels. This kind of plate is widely used in building materials, packaging, medicine and many other industries.

Performance Profile

1. High surface hardness, excellent scratch resistance.

2. The surface resistance value is 10 of 6 ~ 10 to the power of 8 ohms, with excellent anti-static function.

3. Outstanding impact resistance and chemical solvent resistance.

4. Beautiful appearance, very smooth and smooth.

5. Light transmittance of more than 73%.

6. It has excellent chemical stability, corrosion resistance, high hardness, high strength, anti-ultraviolet (aging resistance), fire retardant (with self-extinguishing), reliable insulation properties and other characteristics.

Production Process

1. Raw material preparation: The main raw materials include polyvinyl chloride resin, stabilizer, plasticizer, pigment and other possible additives.

2. Mixing and mixing: Put the prepared raw materials into the mixer, stir and mix thoroughly.

3. Pressing molding: The evenly mixed raw materials are fed into the press and pressed under high temperature and pressure to make various specifications of PVC board.

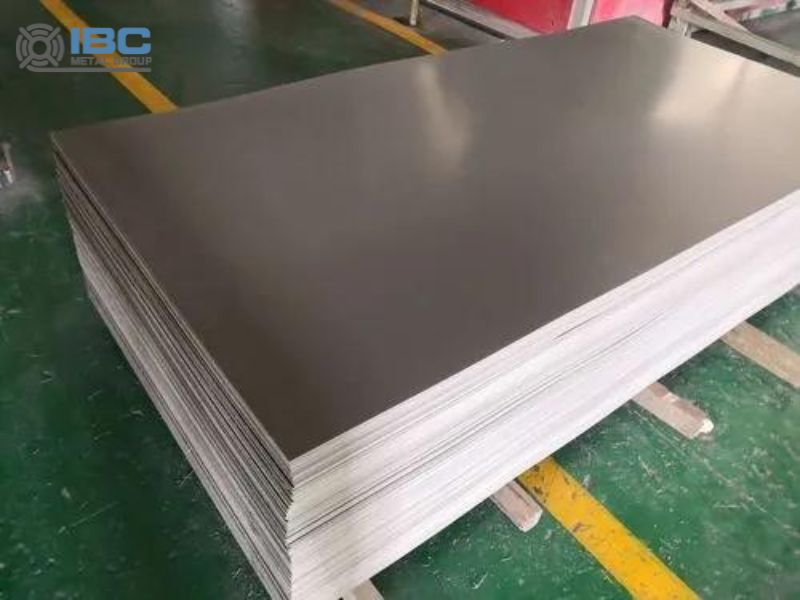

4. Cooling and shaping: Plates fresh out of the press are hot, and workers need to cool them to stabilize their shape.

5. Cutting and finishing: cutting as needed, and then surface treatment and cleaning.

6. Quality testing and packaging: All PVC sheet must undergo strict quality testing to ensure that they meet various performance indicators before packaging.

The Applications of PVC Sheet

1. Construction and decoration field: Because of its excellent durability, fire resistance and easy processing characteristics, it can make indoor and outdoor decoration.

2. Household goods field: Because of its waterproof, moisture-proof, corrosion resistance and other characteristics, it can make furniture, such as cabinets, bathroom cabinets, wardrobes and so on.

3. Electronic products: Because of its insulation, corrosion resistance and portability, it can make the shell and internal structure of electronic products.

4. Agricultural facilities: Because of its durability, corrosion resistance and easy to clean characteristics, it is widely used in the construction of agricultural facilities such as greenhouses and farms.

5. Automotive industry: Because of its excellent weather resistance, insulation and impact resistance characteristics, it is widely used in automotive internal structure and external decoration.

Contact with us today!