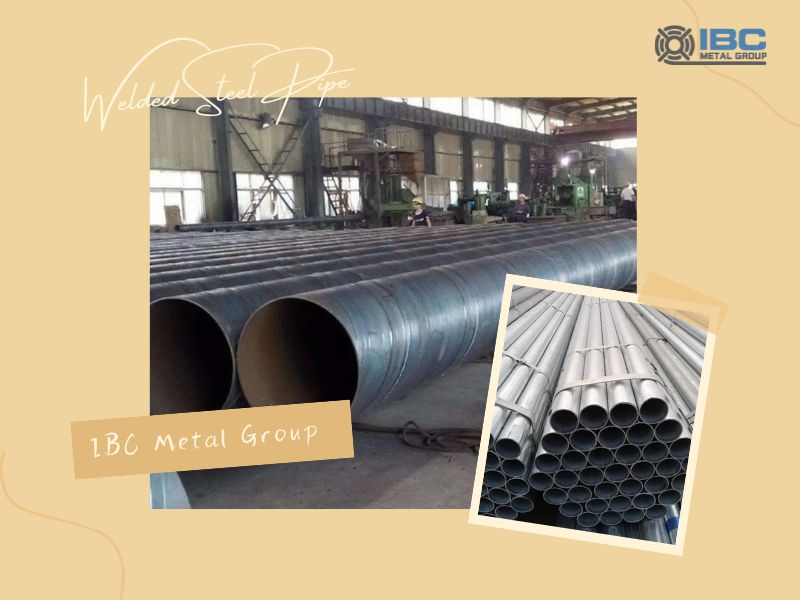

Welded steel pipe refers to the steel strip or steel plate bent and deformed into round, square and other shapes, and then made through the welding process, the surface of the steel pipe with joints. The billet used is mainly steel plate or strip steel.

This kind of steel pipe has many advantages, such as high strength, good corrosion resistance, high welding quality, high dimensional accuracy and convenient construction. So it has been widely used in construction, oil, natural gas, chemical industry, electric power and other fields.

Classification of Welded Steel Pipe

1. High strength characteristics: Its strength is significantly higher than that of ordinary steel pipes, and it can withstand greater pressure and weight. This characteristic makes this steel pipe perform well under heavy loads and high pressure environments. And it is widely used in various engineering fields.

2. Excellent corrosion resistance: Its surface is specially treated to resist corrosion and oxidation, thereby extending its service life. This characteristic allows it to maintain stable performance in humid, corrosive environments.

3. High quality welding process: It adopts advanced welding technology, such as high-frequency welding or arc welding, to ensure that the weld is firm and not easy to crack. This high quality welding process guarantees the overall performance and reliability of the steel pipe.

4. High-precision size: The dimensional accuracy of this steel pipe is extremely high, and it can meet the precise requirements of various complex projects. The high precision makes it more convenient and accurate during connection and installation.

5. Convenience of construction operation: Workers can cut and connect according to actual needs, and the construction process is simple and convenient. In addition, its light weight and easy handling characteristics also reduce construction costs and time.

Applications of Welded Steel Pipe

1. Oil and gas pipeline:

Operation: Welded steel pipe is an important energy resource for transporting oil and natural gas. During the pipeline laying process, this steel pipe is connected by welding technology to form a continuous long distance pipeline. This ensures that oil and gas can be delivered safely and efficiently to its destination.

Applications: Energy transmission and storage systems in buildings such as oil storage tanks, pipeline delivery systems, and oil and gas platforms depend on its robustness and tightness.

2. Construction project:

Operation: In the field of construction, structural support is inseparable from it, such as the steel structure of buildings, the load-bearing part of Bridges, and the support of tunnels. The welding technique assembles them together precisely to form a solid building structure.

Application: Its high strength and load-bearing capacity make it an indispensable material in construction projects to ensure the safety and stability of buildings.

3. Chemical plant pipeline system:

Operation: In chemical plants, it can transport a variety of chemicals. These pipes need to have good corrosion resistance and tightness to ensure the safe transportation of chemicals.

Application: Its application in chemical plants involves many links such as liquid transportation, reactor connection and exhaust gas emission, which is crucial to maintaining the normal operation of chemical production.

4. Mechanical equipment manufacturing:

Operation: It can manufacture large machinery and equipment. And it is also used in the production of ships, automobiles, railway vehicles, etc. During the manufacturing of these devices, welded steel pipes are cut, bent and welded to the desired shape and size.

Application: Its strength and plasticity make it an ideal material in the manufacture of mechanical equipment, able to meet the needs of a variety of complex structures and functions.

Contact with us today!