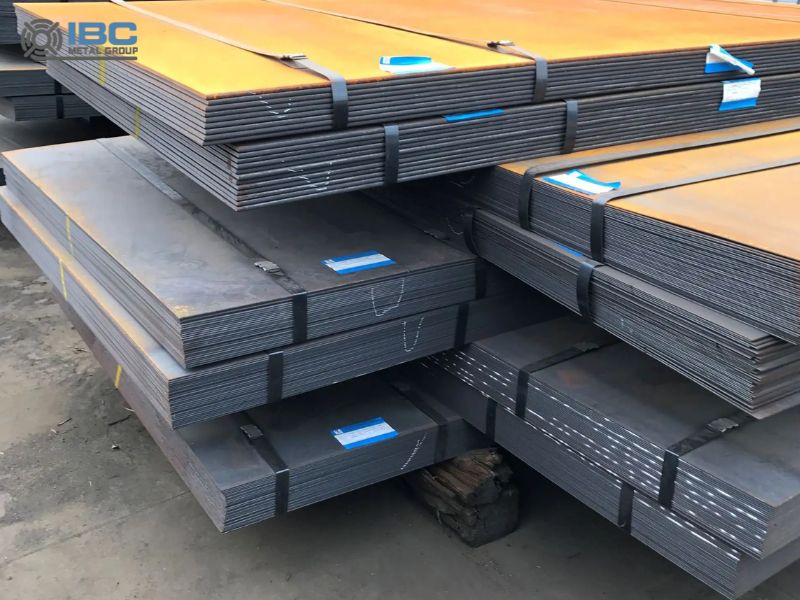

Wear resistant steel plate usually has high hardness, good toughness and excellent wear resistance. These properties are achieved through special alloy compositions and heat treatment processes. It is often used in mining, construction, agriculture, transportation and other industries. Such as excavator bucket, loader shovel, railway switch, bridge protection plate and so on.

Operation Cautions of Wear Resistant Steel Plate

Storage and handling:

Wear resistant steel should be stored in a dry, well-ventilated place to avoid moisture and corrosion. When handling, appropriate lifting equipment and protective pads should be used to prevent the steel plate from being damaged or deformed during handling.

Cutting and machining:

Its cutting and processing usually require the use of professional equipment and tools. When cutting, you can choose flame cutting, laser cutting or plasma cutting methods. During the processing, attention should be paid to protecting the surface of the steel plate to avoid scratches and contamination.

Welding and assembly:

Its welding requires the use of welding materials and welding processes that match the steel plate material. Before welding, oil, rust and other impurities on the surface of the steel plate should be cleaned to ensure the quality of welding. When assembling, it should be carried out in accordance with the design requirements to ensure the coordination and fixed firmly between the parts.

Installation and use:

Workers should pay attention to its placement direction and fixing method when installing. This ensures that its wear resistance can be fully utilized in the working process. During use, they should also regularly check the wear of the steel plate. In addition, damaged parts will be replaced or repaired in a timely manner.

Performance Profile of Wear Resistant Steel Plate

Advantages:

High wear resistance: Its surface is covered with a high-hardness alloy wear-resistant layer. It can resist various wear and abrasion, significantly extending the service life of equipment and structures.

High strength and toughness: wear resistant steel plate not only has high strength, can withstand greater impact and pressure, but also has good toughness, can maintain its shape and performance under high stress.

Good welding and processing performance: it is easy to cut, bend and weld and other processing operations, convenient for equipment maintenance and structural transformation.

Wide range of applications: it has a wide range of applications in metallurgy, coal, cement, electricity, glass, mining, building materials, brick and other industries, with a high cost performance.

Disadvantages:

High cost: Because it uses special processes and materials in the production process, its cost is usually higher than that of ordinary steel plates. It may increase the cost burden of some applications.

Possible surface defects: It may have surface cracks, decarbonization, scratches and other defects in the production process, which may affect its performance and life.

High professional requirements for use and maintenance: The use and maintenance of this steel plate requires a certain amount of professional knowledge and experience, if improper operation may lead to its performance degradation or damage.

Contact with us today!