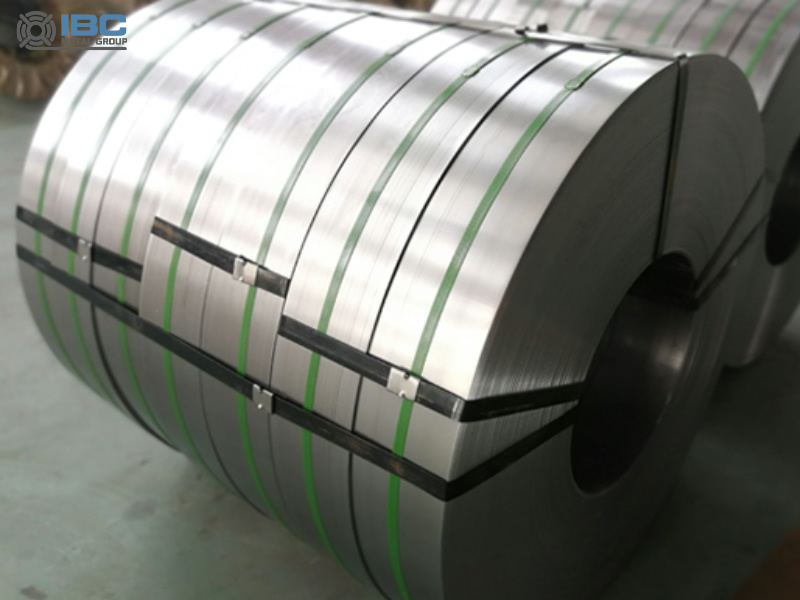

Performance Introduction

1. Excellent corrosion resistance of ZAM Steel Coil

ZAM steel coil has excellent corrosion resistance. And its corrosion resistance can reach 10 to 20 times that of hot galvanized plate. And 5 to 8 times that of hot galvanized aluminum (5%) alloy steel plate. This excellent corrosion resistance enables the coil to perform well in harsh corrosive environments, extending the service life of the product.

2. Good processability

It has excellent scratch resistance, can adapt to various processing methods, and provides convenience for the user’s processing process. In addition, because it does not need to carry out follow-up processing such as hot dip plating after forming processing. It can further simplify the user’s processing process and improve production efficiency.

3. Energy saving and environmental protection

Compared with the traditional galvanized steel sheet, this steel coil can save energy consumption and material use in the production process. It is in line with the development trend of environmental protection and energy saving. At the same time, the aluminum magnesium coating technology also has the characteristics of environmental protection and reliability. It meets the requirements of modern industry for environmental performance.

4. Wide applicability

With its excellent performance, it can be widely used in vehicles, buildings, furniture and other fields. Whether it is used in the automotive industry for anti-corrosion protection of the body and chassis, in the construction industry for anti-corrosion decoration of the roof and wall. Or in the furniture industry for the production of anti-corrosion durable furniture, this steel coil can play its unique advantages.

Applications of ZAM Steel Coils 1

- Aviation:

1. Manufacturing aircraft structural parts: The application of ZAM steel coil in the aviation field is mainly focused on the manufacture of key structural parts of aircraft, such as aircraft fuselage and engine impeller. Due to its excellent high temperature strength and oxidation resistance, it is able to ensure the stability and safety of aircraft in high temperature, high speed flight environments.

2. Improve corrosion resistance: Aircraft often face complex weather and environmental conditions, and its excellent corrosion resistance helps to extend the service life of aircraft and reduce maintenance costs and safety risks caused by corrosion.

- Automotive field

1. Manufacturing auto parts: It plays an important role in automobile manufacturing. And it is used to produce key components such as wheels and frames. Its high strength and excellent formability make automotive parts more robust and durable while reducing the weight of the vehicle, helping to improve fuel efficiency and reduce carbon emissions.

2. Fuel saving and environmental protection contribution: By reducing the weight of the car, this steel coil helps to reduce the fuel consumption of the car, so as to achieve energy saving and emission reduction at the same time, but also in line with the requirements of modern automobile manufacturing industry for green and environmental protection.

Applications of ZAM Steel Coils 2

- Electronic field

1. Mobile device shell material: In the field of electronics, it can manufacture mobile phone, tablet computer and other mobile device shell material. Its high strength, high toughness and corrosion resistance can effectively protect the electronic components inside the equipment from the damage of the external environment, such as impact, scratching and corrosion.

2. Improve product texture and durability: Its appearance has good texture, which can improve the overall beauty of mobile devices. At the same time, its durability also helps to improve the service life of the product and reduce the maintenance rate, thus enhancing the user experience and brand image.

Why IBC Group

1. Advanced technology and equipment:

IBC Group has advanced smelting, rolling and processing technology to ensure the quality and performance of steel.

The group has introduced advanced production equipment, realized the automation and intelligence of the production process, and improved the production efficiency.

2. High quality raw material supply:

The Group has established a stable raw material supply system. It ensures the use of high-quality ores and auxiliary materials, laying the foundation for the production of high-quality steel.

3. Rich product lines and customized services:

The Group provides diversified steel products, covering construction, Bridges, machinery manufacturing and other fields, to meet the needs of different customers.

In addition, IBC Steel Group provides customized services to produce steel with specific specifications and properties according to the specific needs of customers.

4. Strict quality control system:

IBC Group has established a strict quality control system, from raw material procurement to product delivery, every link is strictly tested and monitored.

The Group has also passed international quality certifications such as ISO 9001, further proving the reliability and stability of its products.

Contact with us today!