Product Property

Elastic limit: spring steel round bar has excellent elastic deformation ability. This means that when subjected to external forces, it is able to undergo elastic deformation and quickly return to its original state after being removed by external forces.

Strength limit: It has a high strength and can withstand greater external forces without plastic deformation or fracture.

Fatigue limit: When subjected to alternating stress for a long time, it can maintain its elasticity and strength, and is not easy to fatigue damage.

Toughness: This steel has good toughness, can resist the impact and extrusion of external forces, and is not easy to brittle fracture.

Wear resistance: After proper heat treatment, it can improve its wear resistance and reduce wear caused by friction during use.

Corrosion resistance: Some specially treated spring steels also have good corrosion resistance. So they can be used in humid or corrosive environments for a long time without damage.

Advantages of Spring Steel Round Bar

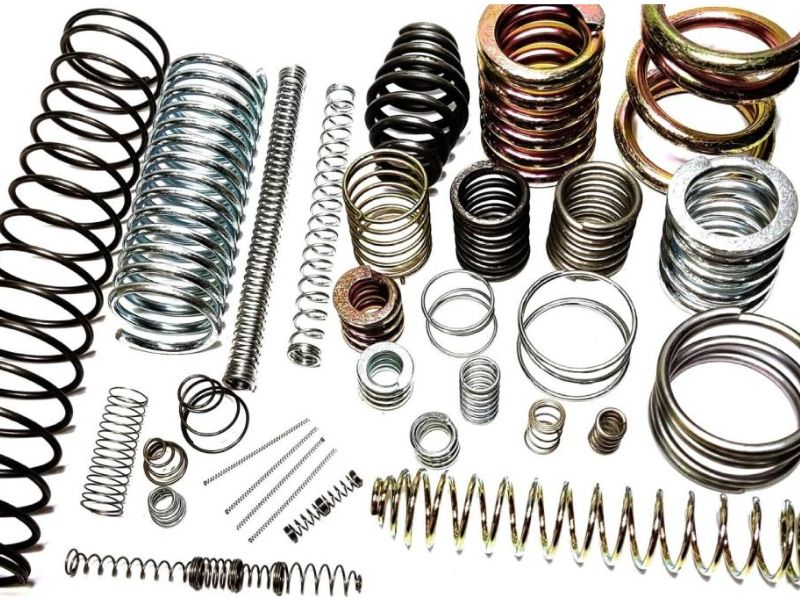

Wide range of applications: Because of its unique properties, it can manufacture a variety of springs and other elastic components. Such as clutch spring, brake spring, automobile and tractor coil spring, etc.

High strength and reliability: The high strength and fatigue limit of the spring steel round bar ensure its reliability and stability during use. This reduces equipment failures and safety incidents due to spring failure.

Good process performance: the product has good hardenability and low overheating, decarbonization sensitivity, easy processing and heat treatment, improve production efficiency.

Optimized material utilization: Its material and size can be selected and matched according to actual needs. This greatly optimizes material utilization and reduces production costs.

Application of Spring Steel Round Bar

1. Automobile manufacturing: Spring steel rond bar plays an important role in automobile manufacturing. It can manufacture automotive suspension systems, shock absorbers, clutch springs, etc. These components are essential for the handling, comfort and safety of the car.

2. Mechanical manufacturing: In the field of mechanical manufacturing, this steel can be made of various springs, such as compression springs, tensile springs and torsion springs. These springs play the role of cushioning, energy storage and transmission in mechanical equipment.

3. Electronic appliances: In the electronic and electrical industry, it can manufacture switch contacts, spring pieces and other components.

4. Aerospace: In the aerospace field, spring steel can manufacture key components of aircraft, rockets and other aircraft because of its high strength, high toughness and lightweight characteristics. Such as landing gear springs, engine blades, etc.

5. Other fields: In addition, medical equipment, stationery manufacturing, toy manufacturing and other fields are also inseparable from it. Such as the manufacture of syringe springs, pen springs, toy springs, etc.

Contact with us today!