IBC Group is one of the top Aluminized Steel Coils Manufacturer & Distributor & suppliers in China. We are an experienced Manufacturing and trading company, which has served customers from 40+ countries, such as Canada, Turkey, Poland, Iran, Brazil, Ukraine, the Philippines, Malaysia, etc. Compared to famous Aluminized steel coil manufacturers, IBC Group offers a more competitive price for the same quality products.

Aluminized Steel Coils

| Standard | GB; EN; ANSI; JIS; |

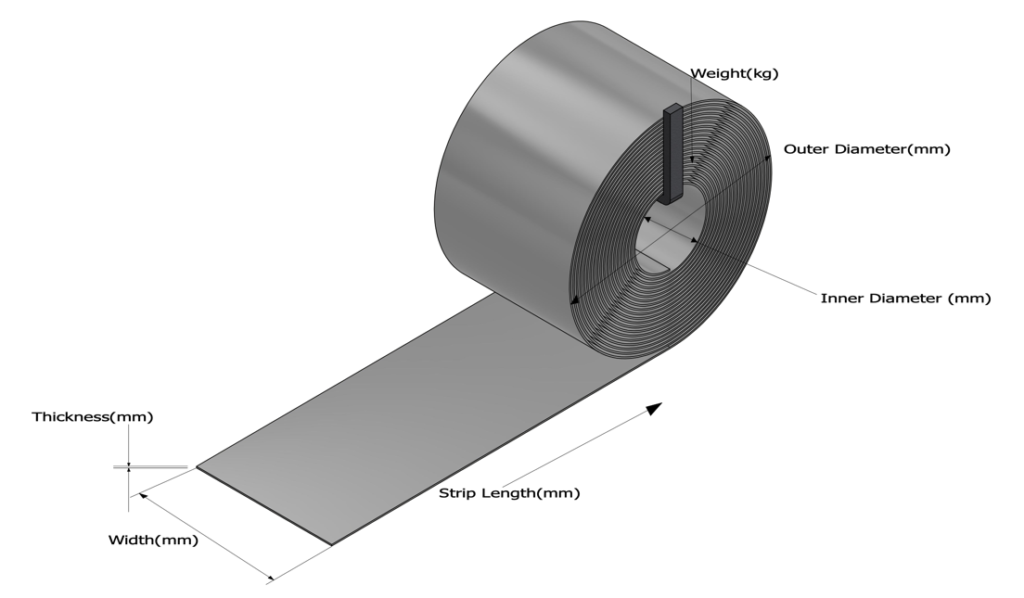

| Thickness | 0.15~6.0 mm |

| Width | 20~2000 mm |

| Coil weight | 3-20tons |

| Monthly Supply: | 8000-15000 tons |

| Alloy | 1000, 2000, 3000, 5000, 7000 , 8000 series |

| Surface Treatment | mill, bright, polished, hair line, brush, sand blast, and etc |

| Packaging | Export standard packing or according to customers’ requirement. |

| Certificate | ISO9001:2008, SGS |

| Shipment | Within 10-15 workdays & 25-30 days quantity >1000 tons. |

| 1000 series | Pure aluminum |

| 2000 series | with copper as the main alloying element |

| 3000 series | with manganese as the main alloying element |

| 4000 series | with silicon as the main alloying element |

| 5000 series | with magnesium as the main alloying element |

| 6000 series | with magnesium as the main alloy element and added Mg and Si as strengthening phases |

| 7000 series | with zinc as the main alloying element |

| 8000 series | with other elements as main alloying elements |

| 9000 series | – |

Aluminum coil is a metal strip made by casting and rolling mill. Aluminized steel sheet and coil are widely used in electronics, packaging, construction, machinery and household appliances, etc. Such as air conditioner and water heaters. According to the different metal elements contained in aluminum coils. Aluminum coils can be roughly divided into 9 categories. For example, 1000, 2000, 3000, 4000, 5000, 6000, 7000, 8000, 9000 series.

In our wide range of products, we also have Aluminized Steel Coil for our clients. Fairly priced, these coils are reckoned for their dimensional accuracy, better performance and rust resistance. Aluminized steel is carbon steel coated with an aluminum-silicon alloy during a hot dipped coated process, which creates a bright appearance and offers heat resistance at a competitive price.

Product Introduction

Aluminized steel plate is a steel plate coated with a layer of pure aluminum. Or aluminum-silicon alloy containing 5% to 10% silicon on the surface of carbon steel. It has good high temperature oxidation resistance. It does not change color for a long time at 450℃. And the maximum use temperature can reach 750℃.

It also has good atmospheric corrosion resistance, especially the corrosion of SO2, H2S, CO2 and other gases. The corrosion resistance is 3-6 times than that of galvanized steel sheet.

Application of Aluminized Steel Coil

Aluminized steel coil is widely used in the automotive industry, heat-resistant appliances and other fields because of its excellent high temperature resistance and corrosion resistance.

Firstly, Automobile industry——Exhaust pipes, silencers, car body chassis, engine heat shields, etc.

Secondly, Home appliances and heat-resistant appliances——Heat exchangers, ovens, furnace linings, chimneys, hot air ducts, grain dryers, furnace reflectors, incinerators, food oven linings, showers, radiators, etc. High-temperature, corrosion-resistant applications that do not require a high strength-to-weight ratio can benefit from aluminized steel.

In conclusion, Products manufactured using aluminized steel include:

- Residential and Commercial Heating,

- Ventilation and Air-Conditioning Systems

- Household Appliances

- Engine Components

Advantages of Aluminized Steel Coils

Firstly, Excellent Corrosion Resistance:

Aluminized steel sheet have excellent corrosion resistance. The dense Al2O3 oxide film formed by the oxidation of aluminum surface isolates the steel base from the oxidizing medium. So that the coating will further corrode even under very harsh environmental conditions. So its resistance. The corrosion effect is very strong. And it also has good corrosion resistance to nitric acid and sea water. The corrosion resistance of aluminized steel products is far greater than that of galvanized products. The corrosion resistance of aluminized silicon products is several to ten times that of galvanized products.

Secondly, Good High Temperature Resistance:

Aluminized steel sheet have good high temperature resistance. They also have extremely high reflectivity at a temperature of 450°C. They will hardly change after long-term use below 550°C. Aluminium coated steel sheet will maintain a bright appearance.

Thirdly, Excellent Heat Reflectivity:

Aluminized steel sheet have excellent heat reflectivity. It has a light reflectivity of about 80% at temperatures below 500°C and a reflectivity of 95% under infrared light. Therefore, it can be used as effective thermal barriers or thermal reflectors in high temperature applications.

We also offer Steel pipe & hollow section for sale. ZN-AL-MG and Aluminized steel pipe, and even Pipeline Fabrication. Also, IBC Group provide other value-added services, such as profiling, shearing, cutting, etc.

Need More Information, Please contact with us!

Related Products

Related Resources

Contact With IBC