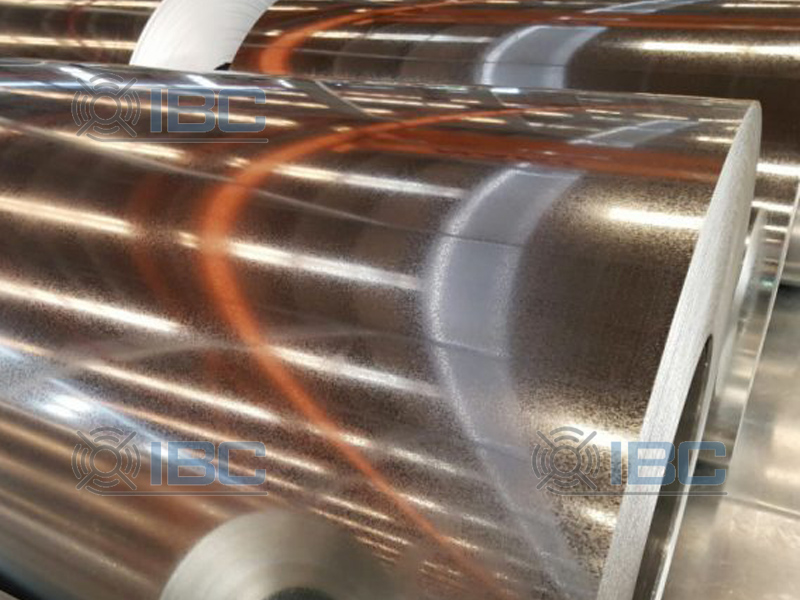

IBC Steel Group’s galvanized steel sheet products have been developed to meet the strict requirements of demanding customers. Our goal is to help people and contribute to society by manufacturing these and other products which provide high quality and performance. So how many kinds of galvanized steel sheet in performance?

According to the mechanical properties of the product, we divided the galvanized sheets into full hard board, building board, stamping board and structural board. Of course, different performance products use different original plates, and the annealing process on the galvanizing line is also different.

Ordinary chilled plates, such as re-crystallization annealing in a heating furnace, produce products that are commercial grade building materials; If incomplete re-crystallization annealing performed in a heating furnace. The product performance is similar to that of a chilled plate, that is, hard Board.

Stamping plates need to produce with cold-rolled plates with lower carbon content. In recent years, with the development of furnace technology. So a large number of cold-hard plates used to directly produce stamping plates. The carbon content of the original plates required for different groups of stamping plates required. Different from impurity element requirements.

We use structural steel original plate to produce the structural plates. Which have a high carbon content and some alloy elements, so the strength is high.

Firstly, Full Hard Galvanized Steel Sheet.

The full plate refers to a product produced by galvanizing using a chilled plate. Which completely recrystallized and annealed on the galvanizing line. And heated to only 550 degrees to reach a semi-annealed state. Its performance characteristics are relatively hard, similar to chilled boards, generally used in special occasions that do not require processing.

The applications of steel sheets in daily life are constantly expanding. Coated steel products such as IBC Steel Group‘s galvanized steel sheets have enjoyed particularly strong growth in fields where corrosion resistance and cost reduction by process omission are important.

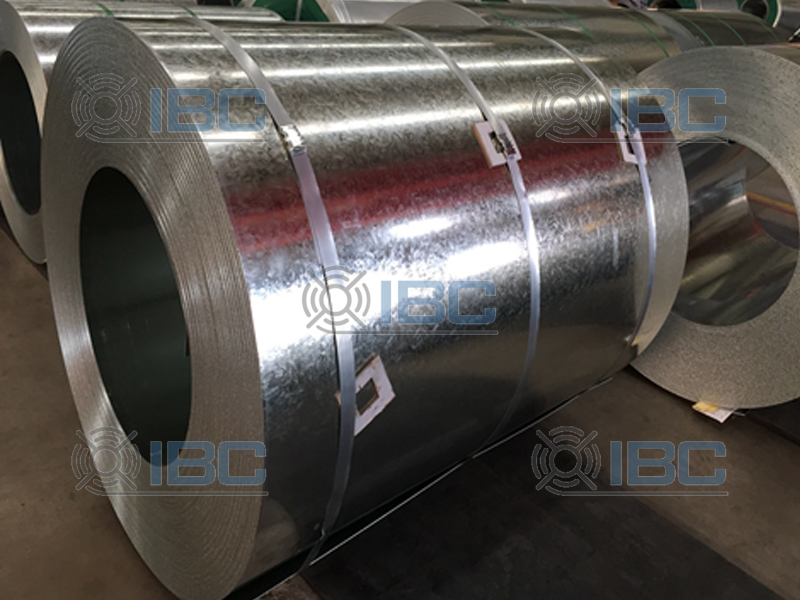

Secondly, Building Material Galvanized Sheet.

Commercial grade building board refers to the production of chilled sheet. Galvanized after recrystallization annealing on galvanizing line, the performance level is commercial grade, characterized by better overall performance. It can be easily deformed. And it has a certain strength, which can meet the needs of most industrial and agricultural applications. Commonly used galvanized sheet product. And also used as a raw material substrate for color coated sheets.

Our coated steel sheets offer superior economy in construction and automotive applications, electric appliances, and electronic equipment. IBC Steel Group, who holds ISO 9001, QS-9000 and ISO 14001 certifications. We made an effort for development and production of various kinds of hot dip galvanized products. Thanks to most modern facilities and long time accumulated technologies.

Thirdly, Stamped Galvanized Sheet.

Stamped galvanized sheet is mainly using in two major categories of home appliances and automotive panels. The home appliance board generally produced by the original board similar to 08A1. Heated to about 800 degrees in the heating furnace, and its performance level is stamping grade. Automobile panels generally produced using gap-free atomic steel as the original plate. Heated to about 850 degrees in a heating furnace, and its performance is deep-drawing and ultra-deep.

IBC Steel Group’s wide range of hot dip galvanized products include pure zinc coated, alloy coated, and unique high corrosion resistance chemically treated steel sheets which respond to the increasingly advanced and diverse needs of changing markets. As the results, we have got sincere reliance from the domestic and overseas customers. Understanding the excellent characteristics of IBC products aiming future progress.

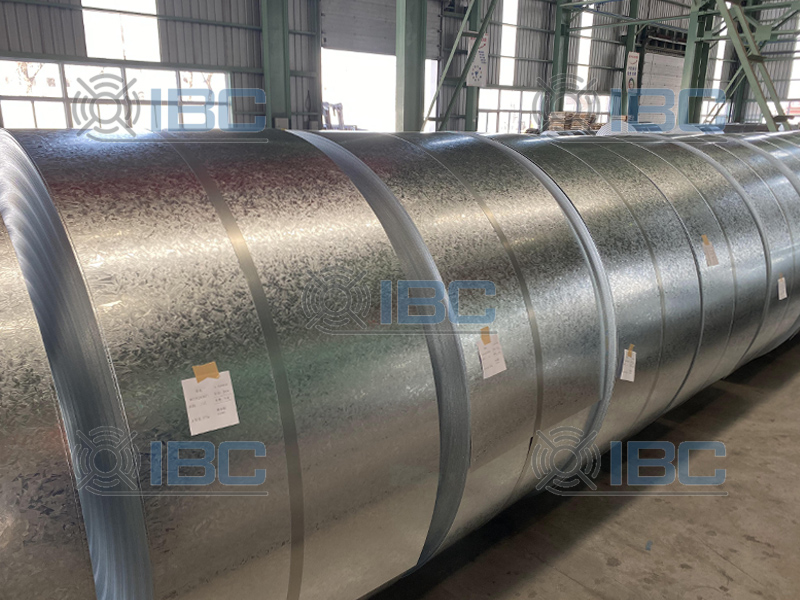

Fourthly, Structure galvanized.

Structural galvanized sheet making from structural high-carbon steel. Even alloy steel plate as raw material, fully recrystallized and annealed after galvanizing on galvanizing line. And its performance characteristics are yield strength and resistance. The tensile strength is higher. And the elongation is slightly lower. Because of the use of engineering structures and the like.

In conclusion, IBC Steel Group products have superior corrosion resistance. Thanks to a thicker coating layer than thin coated sheets with high formability and weldability. Produced by the continuous galvanizing line. Products has good coating adhesion and formability, combined with excellent corrosion resistance and lubricity imparted by various chemical treatments.

If you want to import GOOD QUALITY Steel Coils from China, please contact us at:

- Mobile: +86-15222480985

- Tel: +86-22-27168866

- E-mail: [email protected]