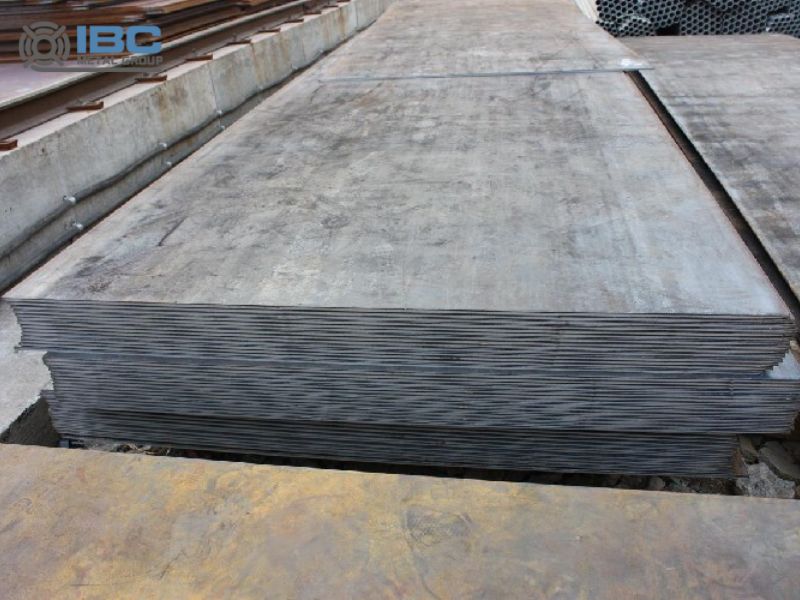

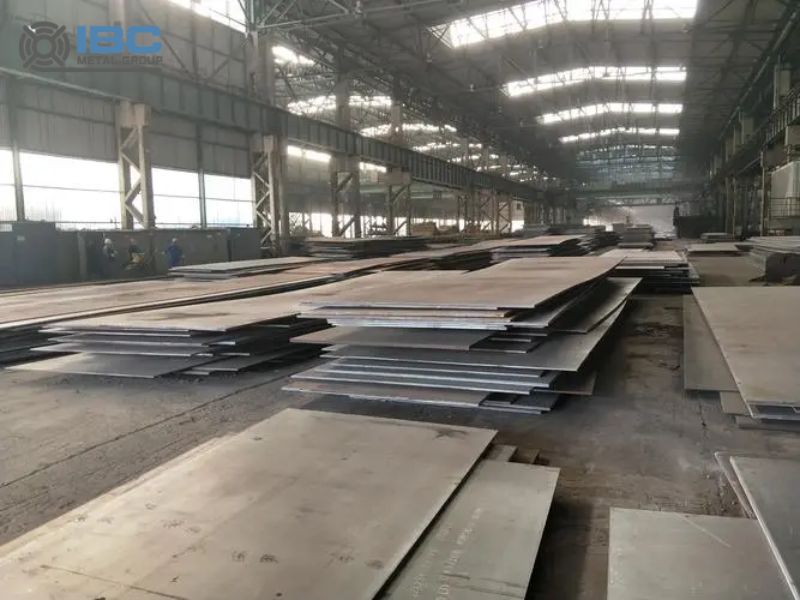

Wear resistant steel plate is a sheet product made of a layer or multiple layers of alloy wear-resistant layer with high hardness and good wear resistance by surfacing welding on the surface of ordinary low carbon steel or low alloy steel with good toughness and plasticity.

It consists of two parts: low carbon steel plate and alloy wear-resistant layer. The wear layer of the alloy is generally 1/3 ~ 1/2 of the total thickness. When working, the matrix provides comprehensive properties such as strength, toughness and plasticity to resist external forces. The alloy wear layer provides wear resistance to meet the requirements of the specified working conditions. If you want to know more, please contact IBC Group!

How to Make Wear Resistant Steel Plate 1

1. Raw material screening: strictly control the content of chromium between 12% and 27% to ensure the excellent wear resistance of the material. At the same time, select the raw materials that meet the requirements, including steel, alloy elements, etc.

2. Melting and continuous casting: raw materials such as molten iron and alloying elements are melted into molten steel in a high-temperature melting furnace. The molten steel is then poured into a continuous casting machine. It is cooled and solidified to form a billet.

3. Heating and rolling: Workers will heat the billet to a certain temperature, so that it has good plasticity and ductility. Rolled billets become steel plates of the desired thickness.

4. Heat treatment: Heat treatment of the rolled steel plate, including heating, insulation, cooling and other treatment, in order to change its mechanical properties and organizational structure, improve the hardness and wear resistance of steel. The general factory will use the quenching and tempering process. Tempering is heating the product to a certain temperature after quenching. And cool it after holding it for a period of time to reduce hardness and improve toughness. At the same time, the stress caused by quenching can be eliminated.

How to Make Wear Resistant Steel Plate 2

5. Cutting and forming: Steel plate heat treatment, cutting, punching, bending and other processing to meet customer needs. This step can be done by cutting, gas cutting, plasma cutting or laser cutting. In the molding process, workers should pay attention to prevent cracks, peeling and other defects on the surface. For thick steel plates, heat forming can be used. This can reduce the hardness of the material and improve the molding quality.

6. Surface treatment: In order to improve the wear resistance and service life of steel, workers can carry out surface treatment. Spraying, hard chrome plating and particle strengthening can all accomplish this step.Spraying is to spray the material with good wear resistance on the surface of wear-resistant steel to improve its surface hardness and wear resistance. Hard chromium plating is to soak the surface of the product in a solution containing chromium. The product is then coated with chromium by an electrochemical reaction. This can improve its surface hardness and wear resistance.

Main Function

1. Improve the service life of the equipment: wear resistant steel plate has high wear resistance and high strength characteristics. It can effectively resist material impact and wear, thereby extending the service life of the equipment.

2. Reduce maintenance costs: Due to its long service life, this can reduce the maintenance and replacement frequency of the equipment, thus reducing maintenance costs.

3. Improve production efficiency: This steel plate can maintain the long-term stable operation of the equipment, reduce the production interruption caused by equipment failure, so as to improve production efficiency.

4. Protect the environment: Its long service life can reduce environmental pollution and waste of resources, in line with the requirements of sustainable development.

Applications

1. Thermal power plant:

Due to long-term wear, wear resistant steel plate can be used to replace or reinforce the parts of the cylinder liner of the medium speed coal mill, the nest shell of the fan impeller and the inlet flue of the dust collector.

Operation: During the operation of the thermal power plant, it is necessary to regularly check the wear of these parts. And install and replace the wear-resistant steel plate according to the actual situation.

2. Coal yard:

The lining of the feeding groove and funnel, the bushing of the hopper, the blade of the fan, etc., need to withstand the high-speed impact and wear of the coal material.

Operation: In the operation of the coal yard, these parts should be checked regularly for wear and replace or reinforce with steel plates if necessary.

3. Cement factory:

Chute lining, cyclone dust collector, separator blade and other parts, due to long-term erosion and wear of cement materials, also need to use it.

Operation: In the cement production process, it is necessary to regularly check the wear of these parts. And install and replace the steel plate according to the actual situation.

4. Loading machinery:

The chain plate, hopper liner plate, grab blade plate and other parts of the unloading mill need to use wear-resistant steel plate to improve the service life because of the long-term impact and wear of the material.

Operation: During the use of loading machinery, it is necessary to check the wear of these parts regularly and replace the steel plate in time.

Contact with us today!