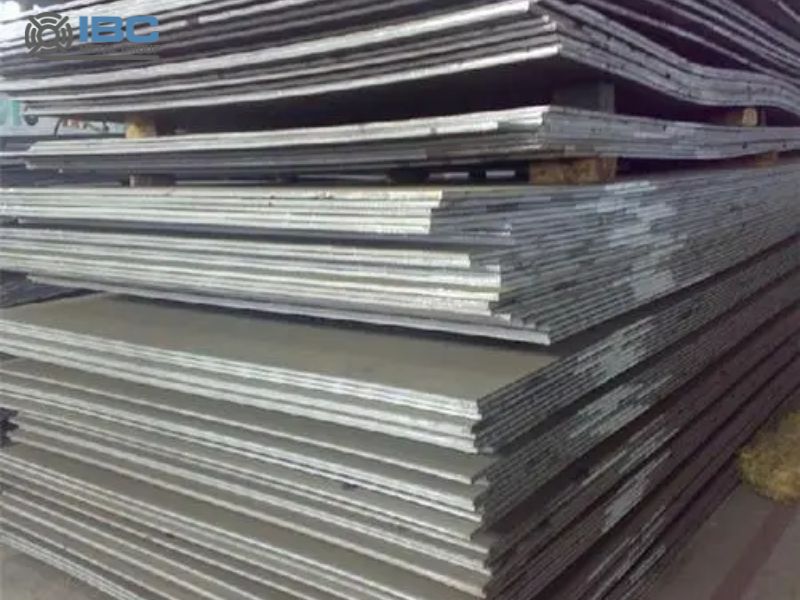

AR200 steel belongs to the wear-resistant steel family and is commonly used in applications requiring high wear resistance and some impact toughness. This steel in the manufacturing process, by optimizing the proportion of alloying elements and heat treatment process to achieve excellent wear resistance and sufficient strength. This kind of steel usually has high hardness and good machinability.

Specifications of AR200 Steel

Product type: Mill Plate, Temper Leveled Plate, Coils

Thickness: 0.500-1.250; 0.100-0.500; 0.188-0.500;

Width: 72-103; 48-96; 60-96;

Length: 120-1020; 72-720;

IBC Group is known for its high quality steel products. The quality of steel directly affects the production efficiency and product quality of customers. So customers are more inclined to choose suppliers with reliable quality and stable performance.

Steel market demand is diverse, customers often need different types and specifications of steel to meet their production needs. IBC Group is able to offer a diverse selection of products that make it easier to meet the specific needs of its customers.

Operating Recommendation

Cutting and processing:

Use appropriate cutting tools and cutting parameters to avoid excessive wear or damage to the tool.

Before processing, workers should fully preheat and cool the steel to improve cutting performance and reduce deformation.

Pay attention to control the cutting speed and feed rate to obtain the best machining results and extend the tool life.

Welding and connection:

Select welding materials and welding processes that match AR200 steel to ensure the quality and strength of welded joints.

Before welding, steel should be cleaned and preheated to remove oil and oxide and improve welding quality.

During the welding process, pay attention to controlling the welding temperature and welding speed to avoid cracks or deformation.

Heat treatment and surface treatment:

According to the specific application needs, the appropriate heat treatment of the steel, such as quenching, tempering, etc., to adjust its mechanical properties and wear resistance.

Workers can sandblast and spray paint the steel surface to improve its corrosion resistance and beauty.

Storage and maintenance:

Steel should be stored in a dry, ventilated environment to avoid moisture and corrosion.

Regular inspection and maintenance of steel, timely repair and replacement of damaged parts to ensure its normal operation and extend service life.

Advantages

Excellent wear resistance

After special smelting and heat treatment process, this steel has excellent wear resistance. This enables it to maintain long-term stability and good performance in high-wear environments, extending service life and reducing maintenance costs.

Good strength and toughness

It has excellent strength and toughness and is able to withstand heavy loads and high impact forces while maintaining stable performance. This makes it perform well under complex stresses and high loads, and is suitable for a variety of harsh working environments.

Excellent processing properties

It has good machinability and can meet various complex processing needs. Whether it is cutting, welding or forming, it can achieve high precision and high quality processing effects, and improve production efficiency.

Environmental protection and energy saving

It pays attention to environmental protection and energy saving in the production process, adopts advanced smelting technology and equipment, and reduces the pollution to the environment. At the same time, its efficient performance also reduces energy consumption, in line with the requirements of modern industry for sustainable development.

Contact with us today!