Operation Procedure

1. Processing and cutting:

The steel flat bar is cut using shears or saws, depending on the desired length. Ensure that the cutting surface is smooth, without obvious burrs or bumps.

If the steel needs to be bent to fit a particular shape or structure, it can be done using a pipe bender or a manual bending tool. During the bending process, it is necessary to ensure that the steel does not break or significantly deform.

2. Installation and connection:

When this kind of steel is used in a building or mechanical structure, it is usually necessary to fix it in the proper position by welding, bolted or riveted.

When welding, it is necessary to ensure the quality of the weld, avoid defects such as slag inclusion and non-fusion, and carry out necessary anti-rust treatment.

Workers choose F-type bolts, select appropriate bolts and nuts, and tighten them according to specifications.

3. Inspection and maintenance:

Check the joints regularly for loosening or rust, and deal with them promptly if necessary.

The factory should take anti-rust and anti-corrosion measures to extend its service life.

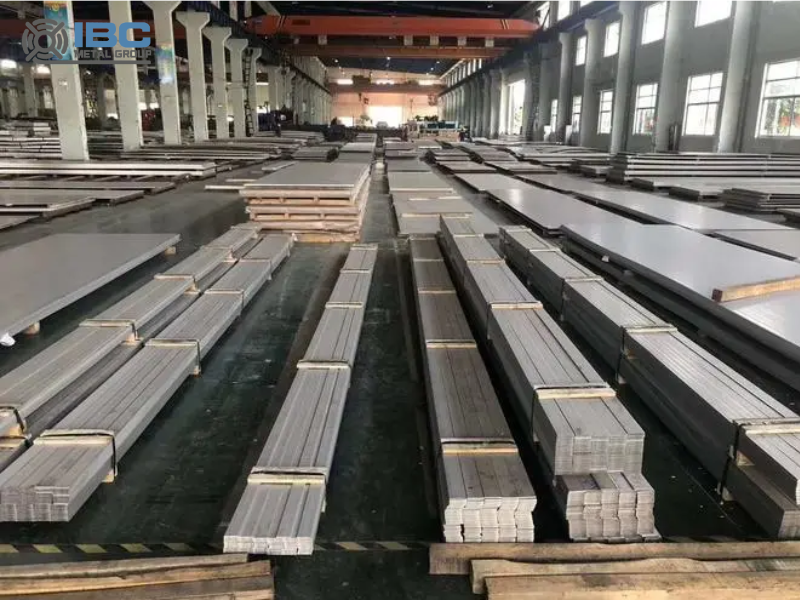

4. Storage and handling:

Workers should store it in a dry, ventilated warehouse to avoid contact with corrosive substances.

In the handling process, be careful to handle gently to avoid scratches or impact resulting in deformation or damage.

Performance of Steel Flat Bar

High strength and excellent toughness: it has a high tensile strength and yield point. And it can withstand large loads, to ensure the safety and stability of the structure. At the same time, it has good toughness and can withstand shock and vibration without breaking, further ensuring the safety of the structure.

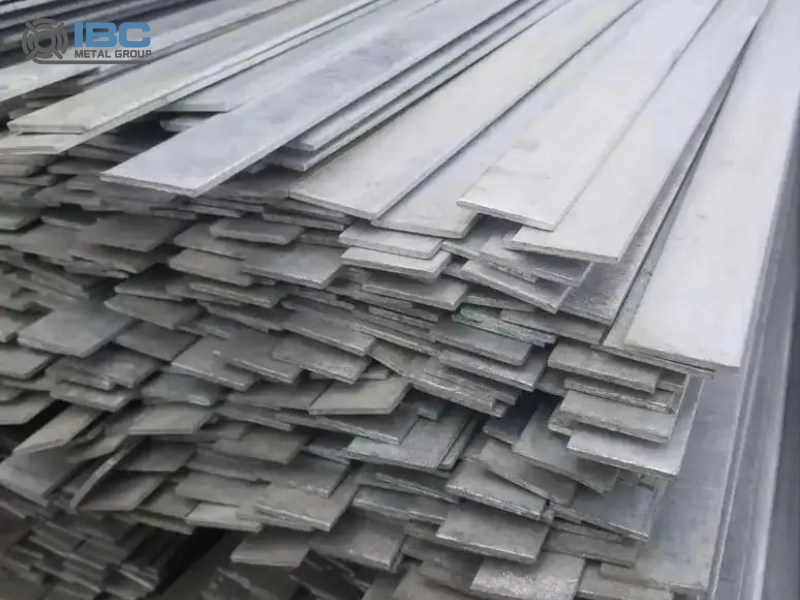

Section shape and size: Its section is rectangular, which helps to reduce the weight of the steel itself and improve the efficiency of use. At the same time, its size is accurate, the surface is smooth and flat, and it is easy to process, weld and install.

Processing performance: Steel flat bar can be easily shear, bending, welding and other processing operations, reducing the difficulty and cost of manufacturing. This ease of processing allows it to be machined into different shapes as needed. The construction of various building structures is inseparable from it. This material can improve the safety and stability of buildings.

Economy: Compared with other high-performance materials, its price is relatively reasonable and has a high cost performance. This makes this steel has been widely used in various fields.

Buy Steel Flat Bar Through IBC Group

1. High quality steel supply:

IBC Group has advanced production equipment and processes, and can provide customers with high-quality steel products to ensure that the strength, toughness, wear resistance and other properties of steel meet the actual needs of customers.

The Group strictly abides by international and domestic quality standards, and carries out strict quality testing and monitoring for each batch of steel to ensure stable and reliable product quality.

2. Personalized customization service:

The Group understands that each customer’s needs are unique and therefore provides a personalized, customized service. Customers can customize steel products with specific specifications according to specific application scenarios and performance requirements.

The group has a professional R & D team and technical personnel, according to the special requirements of customers, to develop and produce customized products to meet customer needs.

3. Technical consultation and support:

We not only provide products, but also provide professional technical advice and support. Customers can consult the Group on the selection, processing, welding and other aspects of steel, and the Group will provide professional advice and guidance.

In the process of use, if customers encounter any technical problems, the group’s technical team will also respond in time to provide customers with solutions.

Contact with us today!