What is ERW Steel Pipe Seamlessness?

ERW steel pipe seamlessness technology divided into geometric seamlessness and physical seamlessness. Geometric seamlessness is to remove the internal and external burrs of ERW steel pipes. With the development of seamlessness technology, The internal burr can be controlled at about -0.2mm ~ O.5mm. Physical seamlessness is to use a medium-frequency induction heating device to heat the weld area to AC3 (927°C), and then perform an air-cooling process with a length of 60m and a speed of 20m/min, and then water-cool when necessary.

What’s the Difference Between ERW Steel Pipe And Seamlessness?

Seamless pipe is formed from a solid steel cylinder that is heated till it is pliable. Then a tool called a mandrel is forced through the center. The cylinder then gets rolled and stretched until it is formed to the specified thickness and diameter.

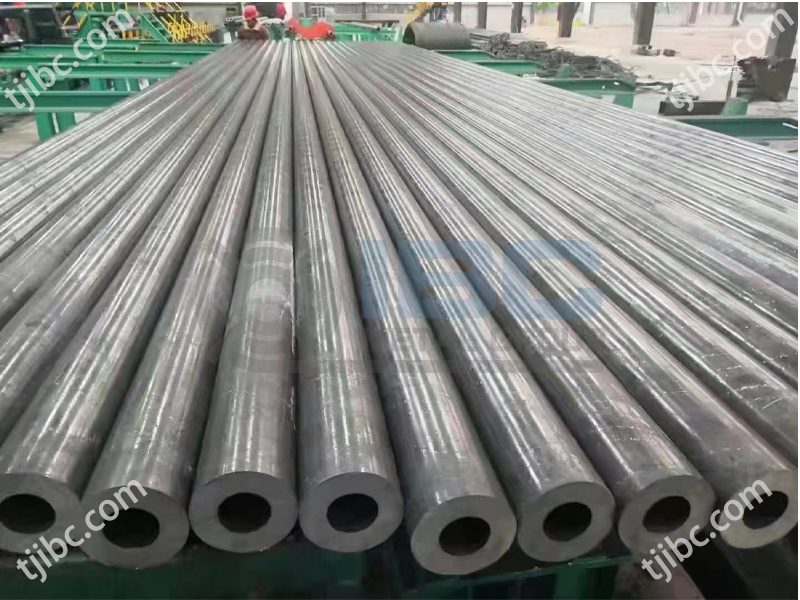

“ERW steel pipe” is straight seam resistance welded pipe, means Electric Resistance Welding, short for ERW, used to transport oil, natural gas and other vapor and liquid objects. The difference between ERW steel pipe and seamless steel pipe is that ERW has a weld seam.

However, welded pipe works a bit differently as it starts as a flat sheet of steel that’s molded into a pipe shape. The two sides of the sheet are welded together, often through a high-frequency electrical current. Although the seams in the electric welded pipe are barely visible, it technically still has a seam.

So far, advanced ERW units in the world have used this method to process welds. The high-quality ERW steel pipe is not only unable to distinguish the weld seam, but also has a weld seam coefficient of 1, which realizes the matching of the weld seam area structure and the base material. Learn more about the difference between seamless pipe and ERW pipe, please have a look at this page “Seamless Pipe vs ERW Pipe”.

We have over 20 years of piping materials making experience and insight into Oil & Gas, Water, Mining, Marine and infrastructure and specializing in the production and sales of carbon steel pipes, alloy pipes, stainless steel pipes, etc., welcome to call us for consultation.

Contact with IBC Metal Group Today!