How Do I Choose the Right Steel Pipe Pile for My Project?

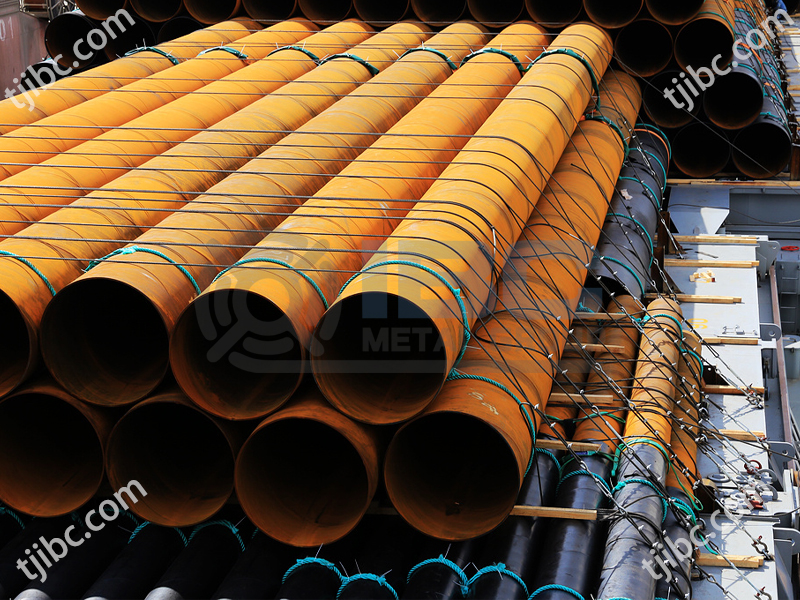

In order to assist you in choosing the right material, IBC Group asks you to provide us with your project information. Our team provides you with the most professional assistance based on all technical aspects, including cost considerations. We can supply pipes in diameters ranging from 21mm to 4267mm with thicknesses ranging from 2.1mm to 100mm. In addition to LSAW pipe, SSAW spiral pipe, and ERW pipe, IBC has delivered thousands of tons of pipe piling globally.

What Type and Grade of Steel Pipe are Used for Piling Works?

The ASTM-A252 specification governs seamless and welded steel pipes used for piling. It can be used as a load bearing pile or as an encasement for concrete piles. A-252 pipes have three grades: Grade 1 (minimum yield strength of 30 ksi or 207 MPa); Grade 2 (minimum yield strength of 35 ksi or 241 MPa); and Grade 3 (minimum yield strength of 45 ksi or 310 MPa). For pilings, Grade 3 is usually preferred.

What is a Friction Pile?

Because friction piles do not anchor in rock layers or hard strata, they are referred to as floating piles. Friction piles are strong and stable due to their adhesion to the mounting soil. By friction, they transmit loads throughout their entire driven height and cylindrical surface to the ground. They are suited for deep soil layers that cannot be reached economically or practically. Because open-ended pipe piles cut through and do not push away surrounding soil, they have the best bearing capacity by friction.

What is an End-Bearing Steel Pipe Pile?

Bottom end of end-bearing pile is anchored into rock or dense soil. A pile’s load-bearing capacity is primarily developed at its toe. In contrast to friction piles, these piles transfer loads to the stable strata where they rest, bypassing softer soil layers. They are no different from columns in that they act as columns. Heavy structures are supported by end-bearing piles.

What is “Plugging” and How to Avoid It?

A soil column forms inside open-end pipes during pile driving. The soil column produces sufficient resistance to prevent further soil intrusion and the pile becomes “plugged”. It is necessary to periodically remove soil plugs to aid in driving, but it is not necessary to do so, especially when the pile will not be filled with concrete, sand, or grout. It is still possible to fill or grout the pipe pile without removing the plug, unless the design does not permit it. A significant concern has been the fact that soil plugs make the pipe pile act like a closed-end pile.

What is the Purpose of Open-end Steel Pipe Piles? When Are They Used?

In cases where material fragments, boulders, and rock layers are expected, open-ended pipe piles are used. To increase its toe capacity against stress and damage, open-ended pipes are usually fitted with special driving shoes. As long as soil plugs do not cause problems during pile driving, they do not need to be removed from open-ended pipe piles. Open-ended pipe piles are mainly used in land and offshore structures such as oil and gas platforms and wind turbines. Strong winds, tidal and vessel impacts are examples of situations where they require resistance to horizontal loads and bending moments. Because pipe piles have a constant radius of gyration, they are a good option for jetties and berths that need freestanding columnar strength.

When Are Closed-End Steel Pipe Piles Used? What Are Their Purposes?

If the entire pile toe is required for bearing, the piles can be closed with either a flat plate or conical tip. In loose sands, pipe piles behave as displacement piles but also function as friction piles. It is still possible to use pipe piles as high-capacity end-bearing piles, whether they are driven open or closed ended.

For pipe piles to penetrate soil layers with rocks or boulders, a 60 degrees conical point is advised. By bringing the reaction force to the centroid of the pile, this tip allows for it to navigate through obstructions and hard strata more easily. This pointed tip also helps safeguard against distortion during driving in challenging conditions.

Contact with us today!