What are the Applications of Structural Steel in the Construction Industry? Depending on its use, structural steel can be formed into different configurations. View it as the backbone of your construction projects, as it’s highly versatile and reliable. There are two main elements of structured steel: iron and carbon. The more carbon added, the stronger the steel. Other chemicals can also be added to enhance strength, reduce cost, or increase ductility.

What are the Applications of Structural Steel

Structured steel is one of the most important resources in the construction industry. Here are some of its most common uses:

Bridges

It is important for bridges to be built from materials that can withstand pressure stress, since thousands or millions of cars pass over them every day. Structured steel has the benefit of being able to be made stronger to serve its purpose, and this is one of its biggest advantages. The construction of bridges requires steel girders, box girders, H girders, truss girders, pipe arch girders, Bailey bridges, accessories, and other miscellaneous items.

High-Rise Buildings

Because steel is strong and flexible, high-rise buildings will not be damaged by wind, earthquakes, or other natural disasters. In addition, steel can be used to speed up the construction process when building high-rise structures.

Industrial Buildings

Structured steel buildings are highly durable and have a high strength-to-weight ratio. The pre-fabricated parts are easy to assemble, and they are also cost-effective. These two factors made structural steel an ideal material for industrial structures, such as workshop plants, processing plants, and power plants.

Residential Buildings

Light gauge steel is the best material for residential buildings that are located near coasts or earthquake faults, as they will last for many years.

Commercial Towers and Public Building

Due to its track record of delivering cost-effective and high-quality structures, structural steel is a great choice for commercial towers and public buildings. In addition to being able to withstand extreme weather conditions like rainstorms, hurricanes, and earthquakes, structural steel is also adjustable and very flexible.

A variety of sizes can be accommodated depending on the building’s design. Its flexibility allows for greater expansion than traditional construction. For example, shopping malls, airport terminals, railway stations, stadiums, museums, art centers, theme parks, etc.

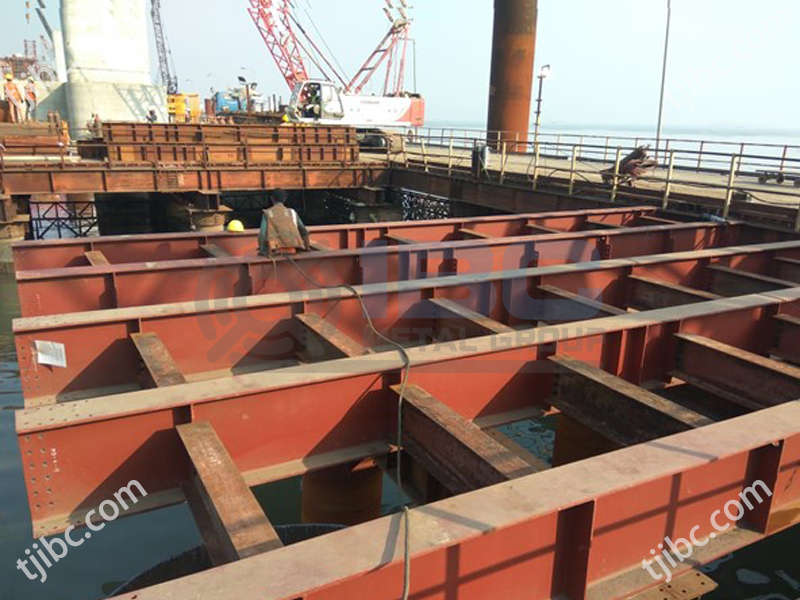

Port Structures and Marine Works

Steel is a suitable choice for port infrastructure and marine structures due to its design load capabilities. It is necessary to put in place a maintenance system as corrosion can occur when exposed to oxygen and salt water. Steel is preferred over reinforced concrete due to the high cost of labor associated with concrete structures. Examples of these structures include pontoons, gangways, headstocks, pile heads, mooring dolphins, berthing dolphins, dredging jackets and accessories, as well as navigation beacons.

Hydro Power & Wind Farm

Construction of hydro power plants and wind farms requires steel. Without it, it would be impossible to create a renewable energy source such as a wind turbine or water power plant. It plays a crucial role in all renewables, especially wind and solar — both require tons of steel. Penstocks, water gates, trash racks, pile legs, towers, foundation embedment.

Modules & Offshore Platforms

Modules & Offshore Platforms – Offshore structures, large oil ducts and drilling structures are made of steel. Usually, the joining material is the same as the base material. Marine structure modules, processing modules, floating modules, subsea modules, platforms, risers and jackets.

Steel Structure Fabrication

It is important to handle steel fabrication correctly, as there are risks involved. A structure’s long-term viability may be compromised if it does not meet industry standards for composition and tolerances. In the US, steel grades are regulated by ASTM International. A third-party fabricator will adhere strictly to industry standards, so you should hire them.

The fabrication process requires the cutting, bending and assembling of steel. Welding is a key part of the process, helping to reinforce structural strength. Among its many benefits, steel is very adaptable and affordable for building projects. Additionally, it’s 100 percent recyclable so it offers a great environmental choice too. To ensure that your project is up to standard, it’s wise to enlist the services of an expert fabricator such as a third-party specialist with years of experience in this field. IBC Steel Structures is the world’s leading supplier of structural steel fabrications. Our goal is to consistently provide high-quality, on-time delivery of our products.

Contact with us today!