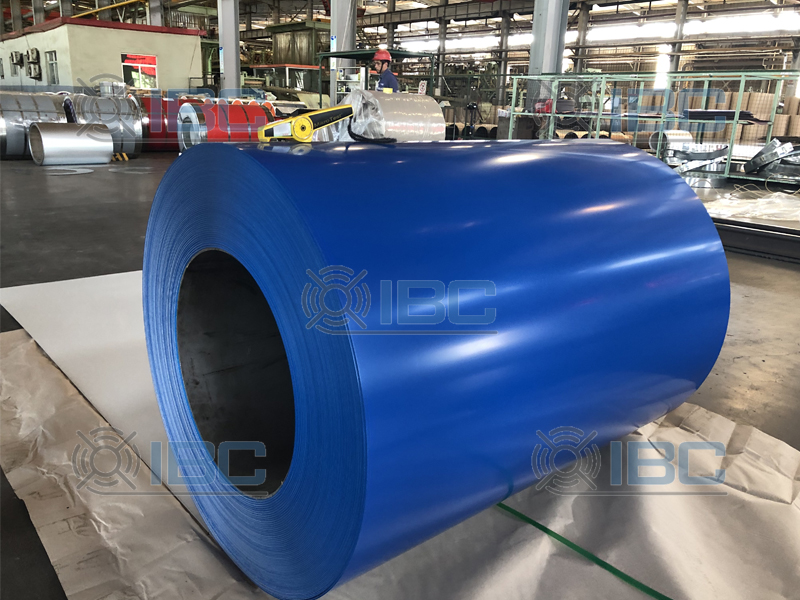

Galvanized Steel Strip Slitting Manufacturing Process

Galvanized Steel Strip Slitting is a metal manufacturing process wherein a galvanized coil slits into the lengths and widths specified by the end user according to their application. As the material runs through the coil slitting machine, the steel rolls are moved through extremely sharp circular blades, making the cuts.

We must apply substantial compressive forces in order to make the slice. It will slices when the forces exceed the tensile strength of the material. The end product is long strips of material cut to the buyer’s specifications.

A steel slitting line machine comprised of three major parts. One is the uncoiler. The second one is the slitter, and together with the recoiler. In order to ensure that the quality of the process is optimized, each element must be precisely aligned during setup.

Our customers appreciate the high level of precision and quality we offer in our slitting process, as it eliminates the excess material waste that can be produced by their own manufacturing processes creating real value.

Strip slitting not only could apply on galvanized coil, it could also used in other material. Such as zinc coating coil, aluminum steel coil, ZAM steel coil and even for stainless steel slitting. For more information, please leave your message.

Production Process of Coil Slitting

Hyrdaulic → Carrying coil car → Hydraulic single arm decoiler → Feeding guide plate fitting → pinching machine, coil shearing → Front looping table → Side guiding fitting → Disc shear → Curling machine → Back looping table → Tension table → Recoiler → Discharging car → Hydraulic control → Electric control

What Does the Steel Strip Used For?

You’ll find steel strip used in many appliances. For example roofing tile, rolling shutter door, house wall panel, vent duct, refrigerators, washers, and dryers. The unique properties of strip steel have also made it a popular material for building and construction materials.

IBC (Tianjin) Industrial Co., Ltd supply a broad range of cold- rolled, galvanized and hot -rolled sheet and plate which have been cut from coils. These sheets and plates can then slit into multiple narrower widths used to fabricate flat bar, tubing and lip channel, or cut to custom lengths to suit fabricators’ and engineers’ specific requirements.

What is Precision Galvanized Steel Strip Slitting

Precision coil steel slitting is a process by which wide coils of steel are fed through a slitter and cut into narrow strips of material. Each of these cut strips known as a strand. And then recoiled to create width narrow slit coil.

Our range of slitting capabilities puts our customers at ease. As they know that we have the right equipment to quickly process their orders. Our customers appreciate our high level of precision in the slitting process, as it spares them from having to deal with excess material waste in their own manufacturing process.

Steel Strip Slitting With Galvanized Longitudinal Edges

We offer hot-dip galvanized slit strip with strip-galvanized longitudinal edges from widths ranging from 58mm to 435mm. That means the steel strip receives all-round corrosion protection. And in combination with very high zinc coatings of up to 1,200 g/m² (Z1200) or zinc-magnesium of up to 1,000 g/m² (ZM1000). It is suitable for the most adverse environments. What is corrosion? Corrosion refers to the surface change or destruction of a metal. This caused by a chemical reaction of a moist steel surface with the oxygen from its ambient air. The material oxidises and forms rust.

In Conclusion

IBC (Tianjin) Industrial Co.,Ltd manufacturer & Supply all kind of strip slitting coil for all over the world. In the metal processing world, every new contract comes as a new and customized challenge. Increased demand for steel coils with finer width and length parameters have ushered in an era of more robust precision slitting – with technological advancements in slitting equipment, software, and tooling practices fueling the wave. We, IBC do the steel products all according to your requirements. No matter what you need, from the little accessories to the large pipes or pipe fittings. We could find the suitable products for you for a whole projects.

Contact with us today!