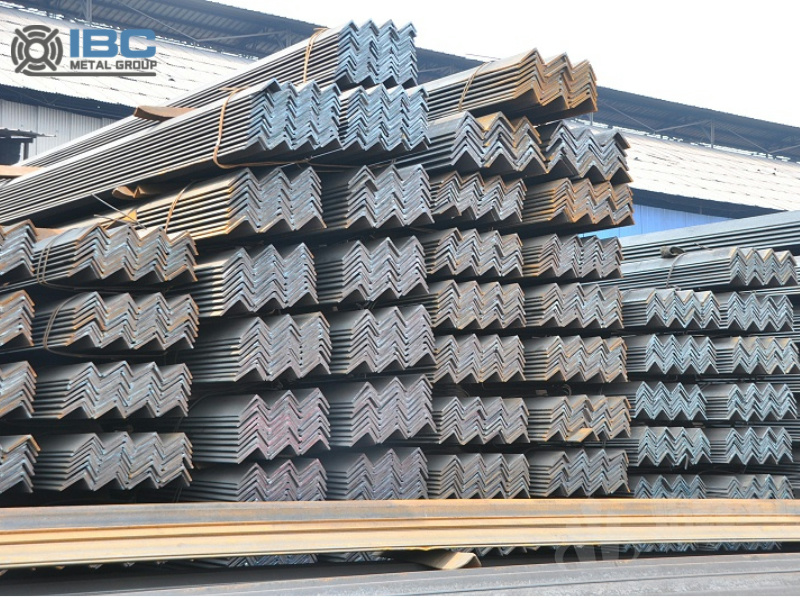

Performance Profile of Hot Rolled Steel Angle

- High strength

Hot rolled steel angle is rolled at high temperature during the production process, and its molecular structure is more compact, so it has higher strength. This high strength makes it able to withstand greater pressure and bending stress, providing stable support for various buildings and mechanical structures.

- Good plasticity

It not only has high strength, but also has good plasticity. When bearing large loads, it can disperse the stress through plastic deformation and reduce the local stress concentration of the structure, thus improving the bearing capacity and stability of the structure.

- Strong corrosion resistance

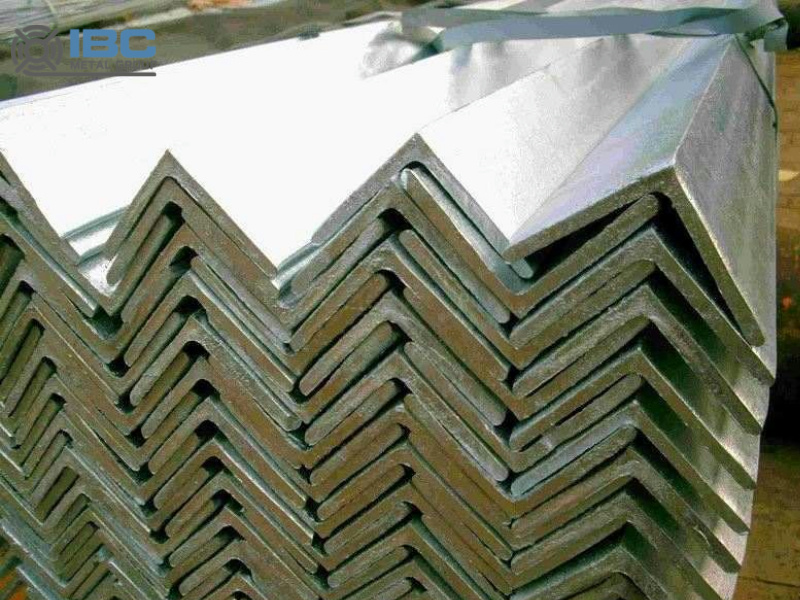

This Angle steel is treated with surface oxidation in the production process. And its surface can resist a certain degree of corrosion. At the same time, the steel treated by hot-dip galvanizing also has good anti-corrosion properties, which can further extend its service life.

- Easy to process

It has a regular “L” shaped section for easy welding, bolting and machining operations. This makes the application of this Angle steel in the construction site more flexible and convenient.

- Good stability

Its cross-section shape is reasonable, the structure is stable, and it can provide more stable and reliable support. In the building structure, this Angle steel can be used as the support of beams, columns, walls and other structures. This can improve the bearing capacity and stability of the building.

- Moderate price

Compared with other high-strength steel, its price is relatively low, making it an ideal choice for low – and middle-income people. At the same time, its wide range of applications also reduces the cost of production and use.

Applications of Hot Rolled Steel Angle

1. Construction field

This product plays an important role in the construction industry. Construction of building frames, supports and other fields are also inseparable from it. Because it can withstand a large load, and can ensure the stability and safety of the building structure. This can enhance the stability and earthquake resistance of the building.

2. Machinery manufacturing field

In machinery manufacturing, it is widely used in the production of various spare parts, lifting mechanisms, bearing supports and so on. These mechanical parts often need to withstand large forces and need to maintain a long service life, and its excellent mechanical properties make it an ideal choice.

3. Industrial equipment field

In the field of industrial equipment, hot rolled steel angle is an important material for making processing equipment and conveying equipment. Its excellent pressure resistance, wear resistance, acid resistance, corrosion resistance and other characteristics make it play a key role in these equipment.

4. Bridge and road laying field

It also plays an important role in the construction of Bridges and roads. Because of its ability to withstand large loads and ensure the stability of the structure, this steel is often used to manufacture structural parts such as the main beam and bridge panels of Bridges to improve the bearing capacity and durability of Bridges. In road laying, it can also be used to build road support structures and guardrails.

IBC Metal Group

- Pre-sales service:

To provide customers with detailed product information and parameter description, to answer customers’ inquiries and questions.

Provide product samples and samples according to customer needs, so that customers can better understand product quality and performance.

Develop suitable product use plans and precautions for customers to help customers better use Angle steel products.

- In-sale service:

Arrange the production and delivery of orders in a timely manner to ensure that customers can receive products on time.

Order tracking service is provided to keep customers informed of the status and location of orders.

Timely answer and deal with the problems encountered by customers in the process of order execution to ensure the smooth execution of orders.

- After-sales service:

Set up a special after-sales service team to provide customers with timely technical support and service guarantee.

Conduct regular customer return visits and satisfaction surveys to understand customer feedback and suggestions on products and services.

To deal with and solve customer feedback problems in a timely manner, improve customer satisfaction and loyalty.

- Value-added services:

Provide product training and technical support services for customers to help customers better grasp the use of products and skills.

Provide customized solutions and consulting services according to customer needs to help customers solve the problems and difficulties encountered in the use of the process.

Establish long-term cooperative relationship with customers, provide customers with preferential policies and preferential activities information, reduce customer procurement costs.

Contact with us today!