As a kind of magnetic material with high performance, silicon steel occupies an important position in modern industry with its unique physical properties and wide application fields. Its excellent magnetic properties, low iron loss, high magnetic induction strength and good processing properties make this steel the material of choice in many fields, providing strong support for the development of modern industry.

Performance of Silicon Steel

Excellent magnetic properties: it has extremely high magnetic permeability, low coercivity and large resistivity. These characteristics make it perform well in the magnetic field, and the hysteresis loss and eddy current loss are relatively small, thus ensuring the efficient and stable operation of the equipment.

Low iron loss: This product has a low iron loss. This means that when the current passes through, it produces less energy loss. This feature is important for energy savings, especially in large-scale applications such as power transmission and conversion processes, which can significantly reduce energy waste.

High magnetic induction: Under a strong magnetic field, it shows a high magnetic induction intensity. This enables the core of motors and transformers made of silicon steel to have a smaller volume and lighter weight, thus achieving efficient utilization of materials and reducing manufacturing costs.

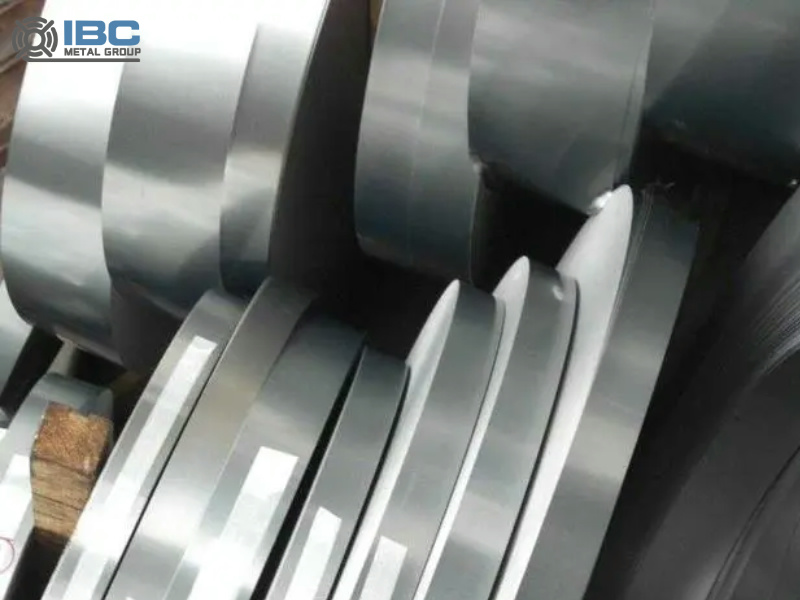

Good processing performance: it needs to have good punching properties, smooth surface and uniform thickness. These characteristics make it easy to meet the needs of various shapes and sizes during processing, while ensuring product quality and stability.

Application in Electromechanical Field

1. Motor manufacturing: It is a key material for manufacturing various types of motors (such as household appliances, industrial motors and automotive motors, etc.). Its characteristics such as low hysteresis, low iron loss and high saturation magnetic induction enable the motor to achieve stable performance with high efficiency and low energy consumption. In the manufacturing process of the motor, this steel, as the main material of the iron core, plays a crucial role in ensuring the performance and stability of the motor.

2. Transformer manufacturing: It is also widely used in various types of transformer manufacturing. By improving the efficiency and load capacity of the transformer, it can reduce the waste and consumption of energy resources. High magnetic orientation silicon steel can effectively reduce no-load loss and transformer noise in power industry applications, and achieve significant energy saving and emission reduction effects.

3. Generator manufacturing: It is also one of the key materials for generator production, which can strengthen the stability and life of the generator.

In addition, this product is also used in the manufacture of various electromechanical equipment such as chokes, electromagnetic mechanisms, relays and measuring instruments. Due to its excellent electromagnetic properties, it is an indispensable magnetic material in the power, telecommunications and instrumentation industries.

Parameter of Silicon Steel

Standard: GB/T 2521-2008

Grades: 50W800, 50W600, 50W470, 65W800, 27Q120, 27Q110, 23Q100, 23Q90, 23Q80

Coating: Organic coating, Semi organic coating, Inorganic coating, Self-bonding coating

Sizes: NGO 0.2-0.65 mm, Iron loss: 2.1–13.0w/kg; GO 0.15-0.35 mm, Iron loss: 0.58–1.3 w/kg

As a leader in the industry, IBC Group has always been customer-centric and committed to providing customers with excellent products and services. In the field of steel products, with deep technical accumulation and strict quality control, we have successfully achieved a comprehensive upgrade of product quality, so as to provide customers with higher quality steel products.

IBC Group adopts advanced production technology and equipment in the production process of products. We have introduced internationally advanced smelting and rolling technology by precisely controlling key parameters such as temperature, pressure and speed in the production process. This ensures uniformity and stability of the product. At the same time, we also use advanced surface treatment technology to improve the corrosion resistance and wear resistance of steel products. This also further extends the service life of the product.

Contact with us today!