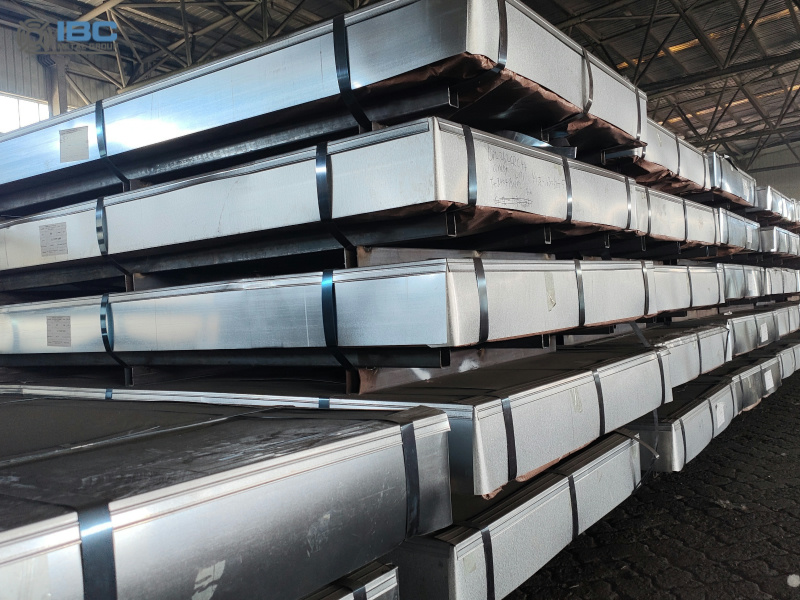

The silicon content of the silicon steel sheet is controlled between 0.5% and 4.5%. It has the characteristics of high permeability, low coercivity and large resistivity. So the hysteresis loss and eddy current loss are small. In addition, its surface is smooth, flat and uniform thickness, good punching property, surface insulation film adhesion and weldability is good. It can prevent corrosion and improve punching property.

These characteristics make this steel plate an indispensable metal functional material in the power, electronics and military industries. It can prepare the iron core of various electric power equipment such as motors, generators and transformers. Therefore, it has become a key material for power equipment to improve efficiency and reduce energy consumption.

Operating Steps

- slice

It is usually supplied in the form of a whole volume. So it first needs to be cut according to specific needs. This is usually done using hydraulic shears or laser cutting machines to ensure the accuracy and surface quality of the cut.

- stamping

Silicon steel sheets need to be stamped into specific shapes and sizes to meet the needs of different equipment. During the stamping process, the silicon steel plate is placed in the mold and formed by the punching machine to achieve the shape and size of the design requirements.

- weld

In processing, workers need to connect different parts. At this time, the welding process will be used, usually using arc welding, gas shielded welding or laser welding methods to ensure the robustness and quality of the welding.

- Surface treatment

In order to improve the corrosion resistance and electromagnetic properties of steel plates, surface treatment is usually required. Common surface treatment methods include hot dip galvanizing, spraying, electroplating, etc. These treatments can protect the silicon steel plate from oxidation and corrosion, while improving its magnetic permeability.

Applications of Silicon Steel Sheet

- Power and electronics industry

It is an indispensable magnetic material in the power, electronics and military industries. It is widely used in motors, transformer cores, relays and various power electronic components and other devices, accounting for more than 90% of the total amount of magnetic materials. As a medium material for magnetic conversion, this steel plate plays a key role in improving the efficiency of electrical equipment and saving energy.

- Special purpose

In addition to conventional applications, it has some special uses. For example, non-oriented and oriented silicon steel strips of specific thickness are commonly used in medium and high frequency motors and transformers, as well as pulse transformers. High-strength cold-rolled silicon steel plates are used for new high-speed motor rotors, while low-carbon silicon steel hot-rolled thick plates and cold-rolled plates are used for magnetic shielding such as medical MRI tomography scanners and high-energy accelerator electromagnets.

- Material preparation

It is also used in the production of silicone rubber, silicone resin, silicone oil and other silicone materials. Silicone rubber is often used to make medical supplies and high temperature gaskets because of its good elasticity and high temperature resistance. Silicone resin is used in the production of insulating paint, high temperature coatings and so on.

- Semiconductor and alloy manufacturing

It is also used to manufacture high-purity semiconductor materials, which are particularly important in the manufacture of modern large-scale integrated circuits. In addition, it is also a key material for the preparation of alloys, such as silicon aluminum alloy. It plays a role in improving the utilization rate of deoxidizer and purifying liquid steel in the steelmaking process.

Contact with us today!