There are some differences between hot-rolled and cold-formed steel sheet piles as finished products, but both products have proven their worth over time and under various circumstances. In the past, hot-rolled sheet piles existed in flat profiles before evolving into U-shapes and Z-shapes. It takes about 50 years for cold-formed sheet piles to be in service – a good reason to be confident about their design and integrity. Aside from their identical physical and mechanical properties, hot-rolled and cold-formed sheet piles are highly recyclable as well.

A hot-rolled steel sheet pile manufactured by heating solid steel or pre-rolled steel to temperatures over 1,2000C and shaping them into the desired profile without delay. What sets them apart is their manufacturing process. A cold-rolled steel sheet pile formed by heating steel coils, then left to cool before being fed through mills to form sections. In spite of the fact that both products considered instrumental in delivering successful projects, gathered data has revealed the following clear advantages of each product:

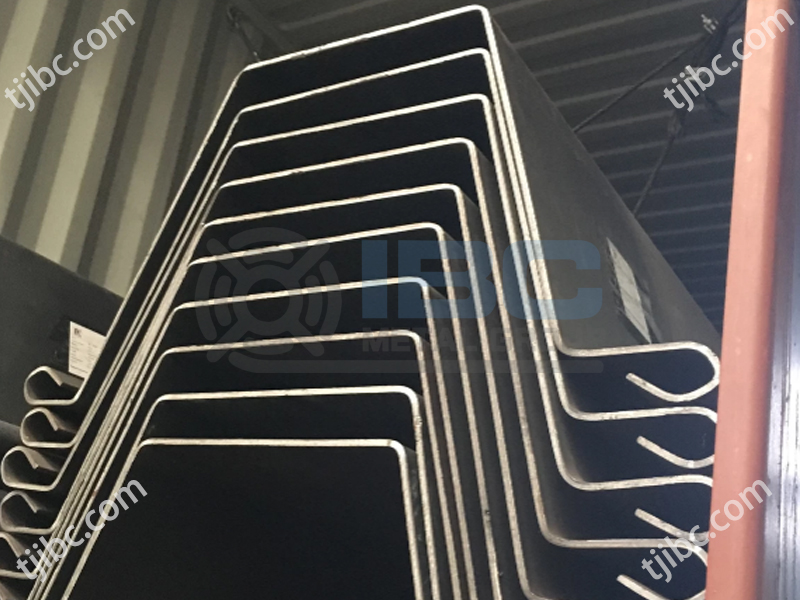

Steel Sheet Piles Made From Hot-Rolled Steel

It appears that Larssen’s interlock is the tightest, as it allows multiple driving and pulling out before it wears out.

This makes them suitable for pile driving in tough ground conditions such as hard soil strata due to their thicker and tighter interlocks than cold-rolled sheet piles.

Hot-rolled sheet pile walls have better water resistance due to tight interlocks.

Interlocking is the major advantage of hot-rolled sheet pile, if not the only one.

Steel Sheet Piles Made From Cold-Formed Steel

Because cold-formed sheet piles are lighter than hot-rolled profiles, they are cheaper and easier to transport compared to hot-rolled ones. Due to the looser interlocks, these preferred by some users and for temporary use.

In spite of the fact that hot-rolled sheet piles are less readily available, cold-rolled sheet piles are more readily available, and millers producing cold-rolled sheet piles greatly outnumber millers producing hot-rolled sheet piles. This provides customers with a shorter lead time and faster material delivery due to the proximity of the sources.

Hot-rolled steel sheet piles typically produced in lengths up to 60 feet. Cold-formed sheet piles come in a range of sizes and sections that allow customers to select the closest, if not exact, sheet pile unit that meets their design requirements. You can order cold-formed steel sheet piles up to 100 feet in length.

When repositioning is necessary due to underlying obstructions, cold-formed sheet piles offer the advantage of allowing up to 25 degrees of alignment.

We offer over 15 series and over 400 profiles in hot rolled sheet piles, cold rolled sheet piles, and cold formed sheet piles in various steel grades and production standards.

Conclusions

IBC sheet piles have been making an impact across the globe for over two decades, on every continent even Antarctica. Their dedication towards meeting delivery timelines and their consistent track record of providing customers with satisfaction make them a go-to supplier for Sheet Piles globally. Be it port and harbor structures, river revetments, retaining walls, cutoff walls, slope protection or cofferdams – IBC has got you covered.

Get in touch with us at [email protected] or T: +86-15222480985 for more info!

Contact with us today!