The main difference between seamless & welded pipes lies in the inclusion of a seamline in the former construction. In addition, differences can be seen in their pressure capacity and cost. Seamless pipes have higher pressure bearing capacity than their welded counterparts, generally 20% more. Therefore, vendors who need to transport substances under high pressure will prefer to use seamless varieties. On the other hand, welded pipes may seem suitable for heavy stress applications; however, as they have a weld seam vulnerability to failure is increased if the heat-affected weld zone is prone to intergranular corrosion. When we talk about the difference between seamless & welded pipe, we should know what the seamless pipe and welded pipe is.

What is a Seamless Pipe?

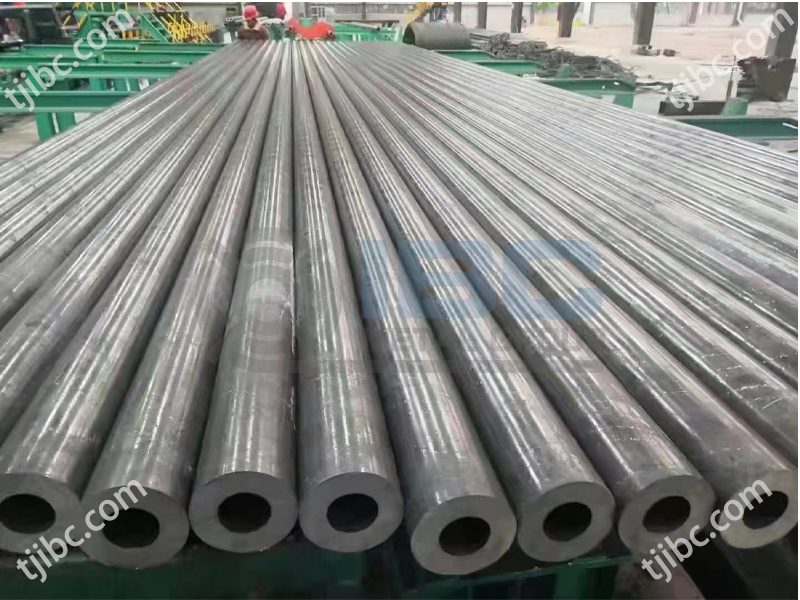

Seamless pipes are created from a solid cylindrical hunk of raw steel known as a round steel billet. The billet is first heated and then stretched or forced over a form, followed by piercing it through the centre with a die and mandrel, thus increasing the inside diameter while decreasing the outer one. Although these pipes can be formed in numerous sizes, their production price rises with an increase in pipe diameter. The name ‘seamless’ comes from its lack of seams. Seamless pipes are extensively used within process piping, pressure vessel construction, power piping, shipbuilding and chemical industries. The Mannesmann method, used to create seamless steel tubes, is a suitable choice for mass production. It is capable of making large diameter pipes with thick walls, and can preserve the original properties of the material. However, the dimensional accuracy of this manufacturing technique isn’t particularly precise.

What is a Welded Pipe?

Using a roller or plate bending machine, flat strips, sheets, or plates are cold formed into welded pipes. A high-energy source is used to weld pipes with or without fillers. Welded pipes are available in large sizes without any size restrictions. They are typically used to transport large quantities of water, oil, or gases. Rather than bar billets, welded pipe materials typically use steel strips (coils). For instance, when it comes to seams welded with resistance welding, the process involves an uncoiler to pull out the steel strip and shape it into a cylinder.

Then, a high-temperature state is created at the joint point that allows for strong rolling and resistance welding. This procedure does not require any welding wire as it uses its own material. After melting welding, we move onto eliminating the excess weld metal (weld bulge) before cooling and straightening/drawing processing. This method is perfect for small batches due to its versatile size configurations and superior dimensional accuracy.

Price Difference Between Seamless and Welded Pipe

The price of welded pipes, due to their metal plates and efficiency of production, is more economical than that of seamless pipes. Seamless pipes require a more laborious manufacturing process which leads to higher costs. Additionally, the pressure capacity of seamless pipes is higher, and they also have fewer chances corrosion; which brings them at higher prices than welded pipes. In conclusion, these cost differences are caused by their method of manufacture, benefits offered, and overall performance.

The Seamless and Welded Pipe Manufacturing Process

Welded pipes are manufactured from metallic sheets with a stated wall thickness that is required by the buyer. The length of the sheet before welding must be cut to match both the inner and outer diameters of the pipe, according to what has been specified. For welded pipes, there are various ASTM standards that must be adhered to during production, usually agreed upon by manufacturers, suppliers, and buyers alike. Seamless pipes require more complicated processes which involve heating the alloy and molding it into a cylindrical shape using a solid billet. This cylinder is then rolled with a piercer point placed in its center so that an even hollow is created. Once complete, any deformities are eliminated through further procedures in order to produce seamless pipes that are smoother and more durable for use in high pressure environments and corrosive settings.

Seamless and Welded Pipe Application

Pipes primarily transport materials, so the right choice of product for any application depends on a number of factors – cost and strength, but also what is being moved and whether the alloy is corrosion-resistant in the operating environment. Different industries utilize pipes including pharmaceuticals, construction, food & beverage, nuclear power, and petrochemicals/natural gas – the latter using them most extensively. Temperature and pressure must also be considered.

And Other Differences

- Strength. In comparison to seamless pipes, welded pipes are believed to withstand 20% less pressure and load as a result of welding.

- Length . Seamless pipes are relatively short in length due to manufacturing difficulties. Welded pipes can be manufactured in long continuous lengths.

- Size. A seamless pipe is typically manufactured in a nominal size of 24 inches or less. Welded pipes are not restricted in size.

- Corrosion Resistance. The sealless pipes are less prone to corrosion, which means they are more corrosion-resistant. Welded pipes, on the other hand, are more prone to corrosion attacks.

- Surface Quality. Seamless pipes have a rough surface due to the extrusion process. Welded pipes have a smooth, high-quality surface.

- Economical. Seamless pipe is more expensive than welded pipe.

- Tests. Welded pipes must be tested before use for weld integrity. Seamless pipes do not require weld integrity testing.

- Availability. The availability of various materials is less, the types of materials are limited, and the delivery time is longer. The availability of various materials is readily available; the delivery time is shorter.

- Wall Thickness. Seamless pipes have inconsistent wall thickness over their length. Welded pipes have more consistent wall thickness.

- Ovality. Seamless pipes provide better ovality and roundness than welded pipes.

- Internal surface check. It is not possible to check the internal surface of welded pipes before they are manufactured.

Have a Project That Needs Steel Pipes?

Whether constructing an edifice or a bridge, steel pipe piles provide the solid foundation necessary to support the load. Seamless pipes can tolerate higher pressure, but this comes with a cost and little versatility. For considerable construction projects, welding offers superior precision while containing costs. For any queries regarding steel pipes for your project, please do not hesitate to reach out to our team.

Contact with IBC Metal Group Today!